Originally posted in Medical Design Technology magazine

Advances in semiconductor design have opened up the possibility of self-powered medical devices in the near future. Typical use cases would be for personal fitness or medical heath monitoring. A self –powered device would be able to energize itself using ambient energy, giving a fully battery-free design, or use the extracted ambient energy to supplement its own battery; thus extending the run-time before a battery change is needed. In some cases, the device may not need battery changes at all during its useful life. This blog discusses some of these applications, and how medical device designers may be able to take advantage of energy harvesting to power their products.

Electronic medical implants have been around for a longtime. However, developing long lasting products has been a challenge for implant designers. Implants have a pre-determined lifetime, most dictated by the longevity of the power source – the battery that runs them. For example, human cardiac pacemakers batteries last anywhere from four to ten years. In case of drug delivery systems such as implantable infusion pumps, the battery life is quite less due to the complex dosing protocols. Some pumps last from a few weeks to a few months, thus requiring frequent replacements. Fortunately, advances in medical, and semiconductor technology brings hope of perpetually powered electronic implants. After all, the body is a vast reservoir of energy. Movement or motion (both synchronous and asynchronous), glucose, heat are some of the potential energy sources within the human body.

How hot is your body?

Heat is particular appealing. It is ever present. What if there was a way to utilize the heat from the human body itself to power medical devices. Such a system would require a way to first convert the body heat into usable electrical energy. Thermoelectric generators – devices that convert a temperature gradient into electrical voltages have been widely used in industrial applications. They are known to be bulky, ruling them useless for small medical applications. But, recent advances in thin-film technology have led to creation of foil-type thermoelectric generators that can reliably produce electric power from body heat. A small -sized generator (called a harvester in energy harvesting terminology) can be placed subcutaneously such that a temperature gradient between the internal human tissue and the skin is able to produce small amounts of power that can be harvested to recharge small batteries, thus extending the run-time. Designed correctly, such a system can provide perpetual power to small devices such as infusion pumps etc.

From micro-watts to milli-watts

But there is one catch. The power produced is likely to be very small, and will need to be boosted to make any difference. Ultra-low power boost converters (energy management ICs) can play a huge role in the boosting process. Advances in semiconductor technologies have led to a whole new category of ultra-low power semiconductor ICs, including low power microprocessors, energy management ICs and RF transceivers (for the radio link in case wireless data capability is desired). TI’s bq25504, bq25505 and bq25570 are part of a family of ultra-low power energy management ICs that allow the small power produced by the harvester to be extracted, conditioned, and eventually stored in a storage element (battery) for later use. The extracted power can be in the order of micro-watts to milli-watts, but still be enough to power ultra-low power ICs, such as a MSP430F59xx microprocessor.

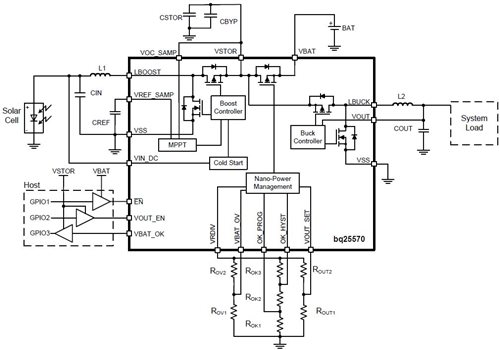

Typical application diagram for the bq25570 nano-power boost charger

Opening doors

Including energy harvesting in implantable electronic medical devices opens the door to “the cloud." Power from energy harvesting can be used to supplement or add new functions previously not possible due to power budget. For example, it may be possible to include energy harvesting in implantable telemetry devices that measure vitals, and upload the data to the cloud for researchers to share. All this with no adverse impact on the power budget of the implantable device, because the extra power needed could be supplemented by energy harvesting.

In addition to implantable devices, there are other categories of medical monitoring products that can benefit from body heat energy harvesting - patches for example. Patches are bandage-like products containing stretchable electronics and very thin batteries. The electronics on the patch performs monitoring and telemetry functions while attached to human skin. Energy harvesting could potentially reduce the size of the batteries on patches, or in some cases completely eliminate them all together.

How about radio frequency power?

While the discussion above has focused on body heat harvesting, energy harvesting ICs are also perfectly suitable for harvesting from radio-frequency. A dedicated radio-frequency source could be used to wirelessly re-charge batteries inside an implantable device, thus allowing the possibility of continuous lifetime operation. Such a system would be of immense benefit where the implantable device also performs data logging function. A perpetually charged battery would eliminate the risk of data corruption or loss due to an inadequately charged or dead battery

Take care of standby power - How active is your monitoring device?

Almost all monitoring devices (or even stimulating devices such as cardiac pacemakers) spend their life in a standby state; periodically waking up to perform the measurement or activity, then going back to standby state. The process repeats for the products life-time. The ratio of active to standby time is critical. As a general rule of thumb, when the ratio exceeds 1:100, the standby current starts dominating the battery life. For energy harvesting to be successful, designers must take care that the product consumes the least amount of power when it is in the standby state, thus reducing the average power requirements. Lowest amount of power in standby state can be ensured by selecting ultra-low power IC for designing the electronic systems. Ultra-low power semiconductor ICs typically consume less that 500 nA in their standby state. Energy harvesting ICs like the bq25570 consume about 700 nA in their active state; and in some cases only 330 nA!

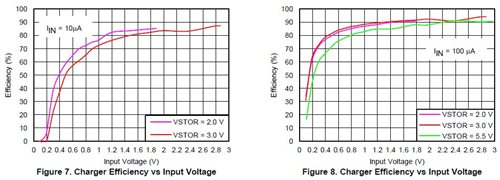

Efficiency for the bq25570

Connecting people and animals with medicine

The days are not far when wearable gadgets like smart watches, bracelets, smart eye wear, and other personal fitness devices will integrate some kind of body sensor to give live feedback to the user. In fact, it is not too difficult to imagine such technology being adopted for life-time animal care, and monitoring. As technology improves, devices will get smaller, facilitating widespread use, ultimately creating sensor networks that will need to be powered perpetually, and often remotely. Energy harvesting will begin to play an integral role in development of these self-powered networks.

Additional resources:

- Download a datasheet or order an evaluation module from the bq25570 nano-power boost controller.

- Check out TI's energy harvesting battery management solutions.

- TI's health tech and medical design applications.