Stubborn vacuum cords, and giant thick AC power plugs for your drill, can be a mess, and can sometimes be hazardous. Enjoying cordless power tools and garden tools used to be an expensive dream, but as Lithium-ion (Li-ion) batteries become more and more popular and less expensive, this dream is finally obtainable!

Clear advantages with using Lithium-ion (Li-ion), Li-polymer or Li-iron phosphate (LiFePO4) chemistries are that they are good in both volumetric (how much energy you get per the size of the battery) and gravimetric (how much energy you get per the weight of the battery) energy density vs conventional batteries. Therefore, you are able to have higher energy without the heavy bulky sized battery of a lead acid, which is ideal if you are thinking of having a power tool or garden tool run off of one. Nevertheless, these chemistries aren’t perfect and are associated with safety concern such as: undervoltage (UV), overvoltage (OV), overtemperature and overcurrent (OC) which can all contribute to accelerating cell degradation and may lead to thermal runaway and system failure.

With the trend of Li-ion battery pack adoption growing and the applications using these chemistries widening, the size of the battery pack itself is growing to demand more power, and so is the number of batteries being built. With widening popularity, people are starting to have more concerns with safety (those mentioned above). Increasing safety concerns has lead designers to consider , more sophisticated protection, monitoring and balancing circuitry in battery-pack designs, while still considering space and thermal constraints.

For this fast pace and growing market in mind, the TI Design, 10s Battery Pack Monitoring, Balancing and Protection Reference Design, provides a tested hardware platform for cell monitoring, balancing, protecting and gauging of a battery pack that uses 10 cells of Li-ion or Li-iron phosphate in series. Such applications include, and are not limited to, power tools, garden tools, robotic and upright vacuums and even drones!

This design consists of:

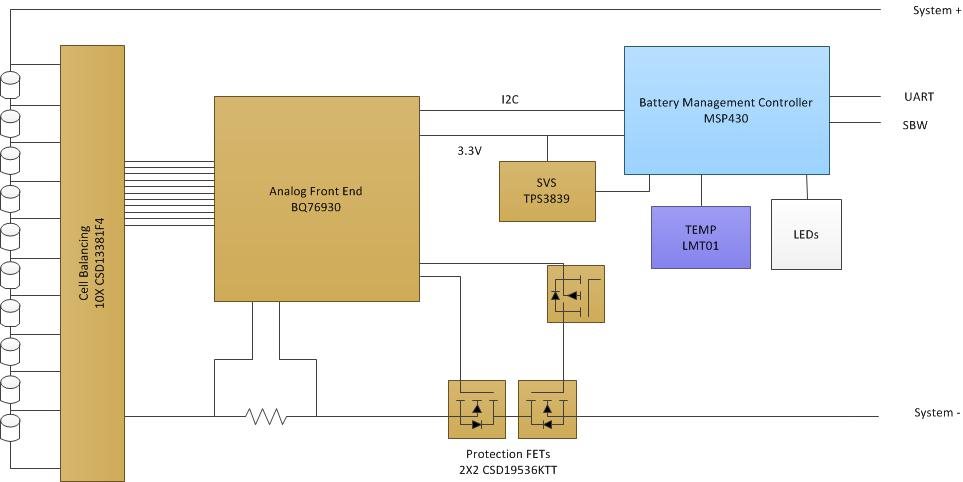

- An analog front end (AFE) that monitors the cell voltage and battery pack, as well as its current and temperature. The AFE includes comprehensive protection, including UV and OV, short circuit, and OC protection. It also drives the cell-balancing circuit.

- A microcontroller (MCU) used as a battery-management controller that enables the configuration of the AFE’s parameters, performing the gas-gauging algorithm and cell-balancing scheme, handling the fault, and communicating with the system outside the battery pack.

- Protection FETs controlled by the AFE that open the circuit when a fault occurs during charge or discharge.

Figure 1: TIDA-00449 System Block Diagram

|

Battery pack configuration |

10S3P (30 to 42V, 12.6Ah) |

|

Maximum continuous discharge current |

50A |

|

Maximum charge current |

10A |

|

UV protection |

2.75V/cell |

|

OV protection |

4.3V/cell |

|

OC protection |

200A for 40ms |

|

Short-circuit protection |

300A for 200µs |

|

Balancing current |

150mA |

Table 1: Reference Design Specifications

When designing battery powered power tools, ensure your pack has the right monitoring, balancing and protection needs against incorrect charging or discharging. With the design guide coupled with this reference design, we have added step-by-step explanations covering component selection, schematics and layout design, and test results including thermal measurements. Get started today and see what power tools you can make cordless!

Additional resources:

- Start desiging today with the 15 Cell Lithium Ion Battery Controller Analog Front End Reference Design.

- Read the application notes for the bq76930.

- Learn more about TI’s brushless DC drivers.