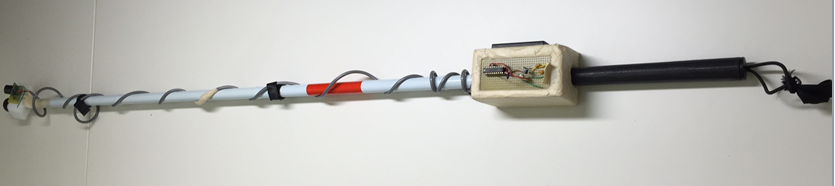

After entering the DIY intern design challenge, my team decided that it would be best to create something that a user could really benefit from. We settled on the idea of an upgraded white cane for the visually impaired that gave variable vibrational feedback to the user. The S.T.I.C (Sonic Technology Integrated Cane) is a white cane that provides a second form of haptic feedback through vibration (Fig. 1). The cane has an ultrasonic sensor mounted on the end to identify objects in the distance, and then convert this information into vibration. This blog will detail how this was achieved, offering you the chance to begin prototyping with an MSP430™ microcontroller (MCU) as well.

Figure 1: Final S.T.I.C design

The concept is very straightforward, as well as the circuitry and required components. In order to build this, we began with a LaunchPad™ development kit for the MSP430G2553 MCU. This provided the means to properly trouble shoot any problems as well as develop our code to provide the variable vibration. By using the Launchpad, as well as a vibration motor and ultrasonic sensor, we were able to get a working prototype up and running.

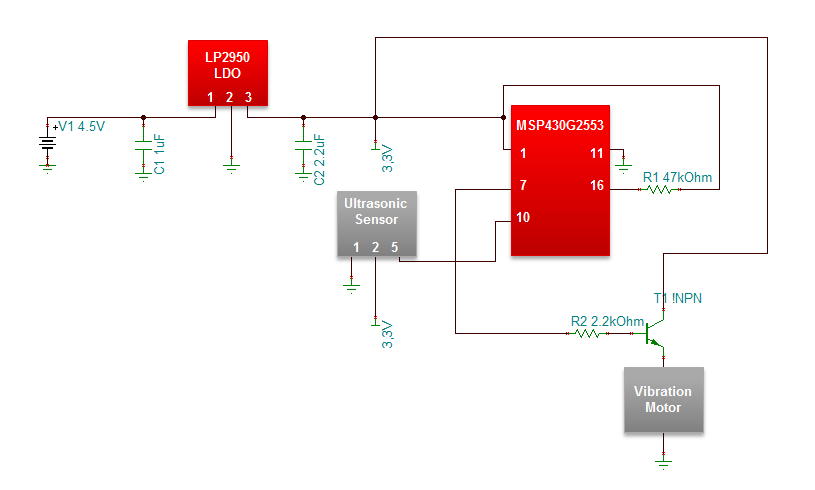

It is easy to see that mounting a LaunchPad kit on a cane is not ideal. To get around this, the LaunchPad kit was used to program the MSP430 MCU, and then the DIP package was removed and mounted on a prototype board to reduce the circuit’s footprint. To input the required 3.3V to the MSP430 MCU, we needed to use three AAA batteries and a linear dropout regulator (LDO) to reduce the voltage from 4.5 to 3.3V. We chose the LP2950 LDO since we needed all through-hole components.

After mounting on a prototype board, an input and output capacitor were used on the LDO to increase stability (1 uF and 2.2uF, respectively). The MSP430 MCU pulse width modulation (PWM) pin was not meant to drive large loads, so we output the signal through a pull up resistor (2.2kohm) to the gate of a bipolar junction transistor (BJT) with the collector going to 3.3V and the emitter connected in series to the vibration motor. The !reset pin on the MSP430 MCU had to be held high during operation, so another pull up resistor (47kohm) was used to link 3.3V to the !reset pin (Fig. 2).

Figure 2: Circuit schematic for S.T.I.C prototype board

Finally, a simple piece of Styrofoam was used to encase the circuit board, batteries and ultrasonic sensor on the end of the cane. The end result is a white cane that will allow the visually impaired to have a second form of haptic feedback when navigating. The vibration is variable, but in our design, we linearly decreased vibration using PWM from 8’ to 6”, changing PWM from 0 to 255 (the max of the MSP430 MCU).

The S.T.I.C offers a very simple project to learn about the MSP430 MCU LaunchPad kit, as well as take it to the next level of actually creating your own circuit using prototyping board. Not only was this a great design challenge, but the end result is something that can be taken further. With more work, this cane could improve the mobility of the visually impaired, and prevent injuries incurred from unseen obstacles such as curbs, walls, etc. Could this be the new standard in white cane technology?

Related Content:

- Get started on developing with the MSP430 MCU LaunchPad development kit.

- Learn more about TI’s DIY intern design page.

- Read the LP2950 datasheet.