Other Parts Discussed in Thread: OPA388, OPA320, LM8272, LM8261, LM8262, LM7321

Hello,

I'm working on a design to "digitize" an old analog vehicle sensor and running into some issues that I believe are tied to trying to drive the SAR ADC in the ECU.

The OEM sensor (see figure below) takes in +5V (provided by ECU) and runs that voltage through a fancy voltage divider and outputs a signal between 0.25V and 4.7V. This output voltage is sent to the ECU which has some R's and C's before it hits the SAR ADC.

I started a design which gets rid of the analog voltage divider and replaces it with a custom CCA which at its heart is a ATMEGA328P Microcontroller. The air flow sensor provides data to the microcontroller which I then use to tell how much voltage the DAC should output.

Originally I had the output of the DAC connected straight to the ECU (i.e. no OpAMP) but during my design I took some amperage measurements on the OEM sensor and saw that the sensor to ECU line had as much as ~115mA on it.... Note that I don't have a ton of confidence in this number, we measured one car and the amperage was 30mA and then measured a second car and and got 115mA... I need to verify these measurements using better equipment but either way since the DAC is only able to output 25mA max, I decided I needed to buffer the output of the DAC.

After doing some research and speaking with TI support I decided to use the TLV4111, a main reason is that I wanted to ensure I could swing close to the rails (same voltage I'm powering the Op Amp with).

I built the digital version both ways, with and without the Op Amp. On the bench, I use a potentiometer to load the output and take voltage and amperage measurements to see how they perform. As expected the one with the DAC starts to drop voltage well before 25mA while the design with the Op Amp can pull nearly 250mA before dropping voltage.

The interesting thing is that when these two devices were installed on a vehicle, it was the "no Op Amp" version that did better. Unfortunately I wasn't present during the testing and don't have any voltage/current measurements but the vehicle without the Op Amp digital design was able to drive (still ran rough) while the Op Amp design was only able to idle and you couldn't even rev up the engine.

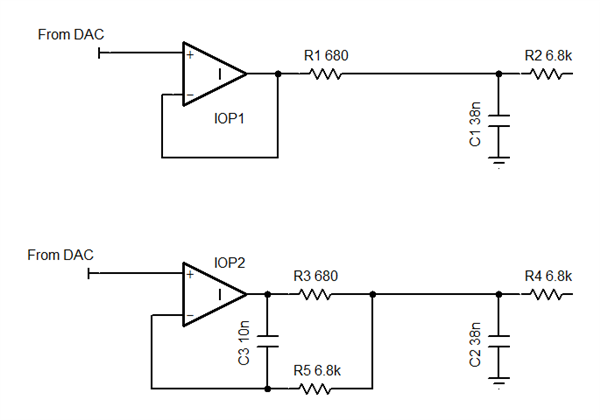

Since I was unable to get any measurements, I decided to get some more data on the ECU (which was unfortunately an unknown at the time) and took it apart to get some data. It turns out the ADC in the ECU is a SAR ADC (Siemends 80C515) that has a 25 to 45pF capacitance. There is a flywheel circuit in front of this ADC which consists of a 38nF cap and 6.8k Ohm resistor. Thus I realized that I was greatly exceeding the capacitance load of the Op Amp (and DAC for that matter too) which is likely causing some instability issues for me. You can see the circuits in the figures attached to this request.

My question is, what are my options here? I looked at circuits to help keep the Op Amp stable, it seems the best one is to put a low value resistor on the output of the Op Amp but I can't do that because I'm trying to swing close to the rails. I started to read about a snubber circuit but I'm not sure if that is suitable here either.