Other Parts Discussed in Thread: TPS7A4001

Hi TI Team,

Need Urgent help,.

We are Using INA213AIDCKR in our Design, we are seeing many random failures in our board due to this device.

Number of failures are increasing day by day.

We have observed that Vref(2.5V) which we are giving to the Ref pin has changed in all the field failure returned Boards.

Currently we are providing Reference voltage(2.5V) through voltage divider circuit,10 is attenuated to 2.5V through 30k & 10K resistor.

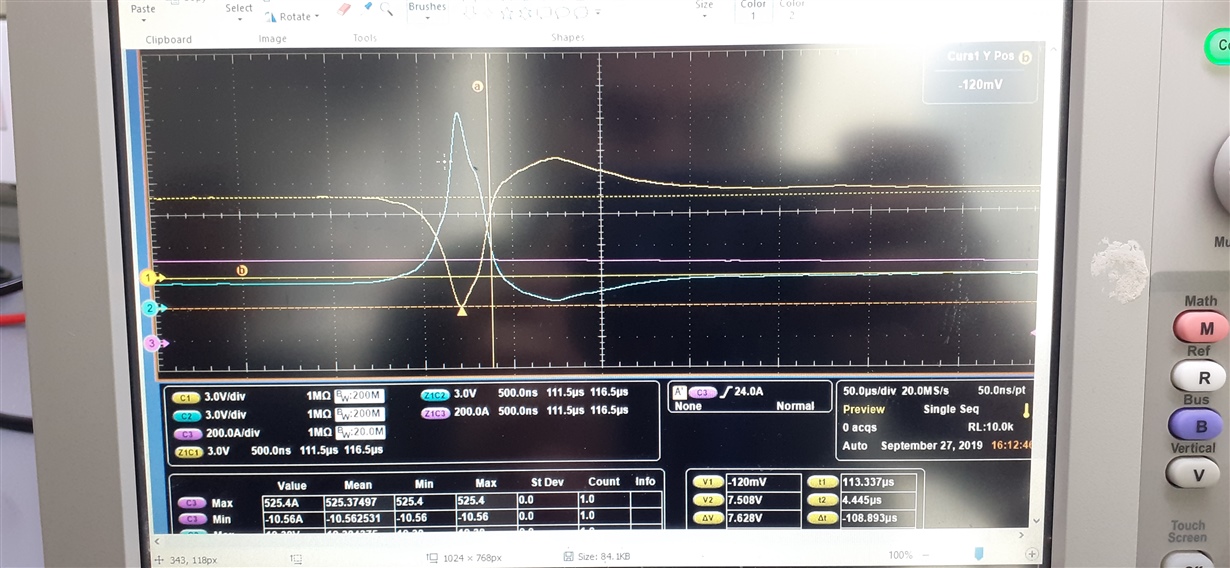

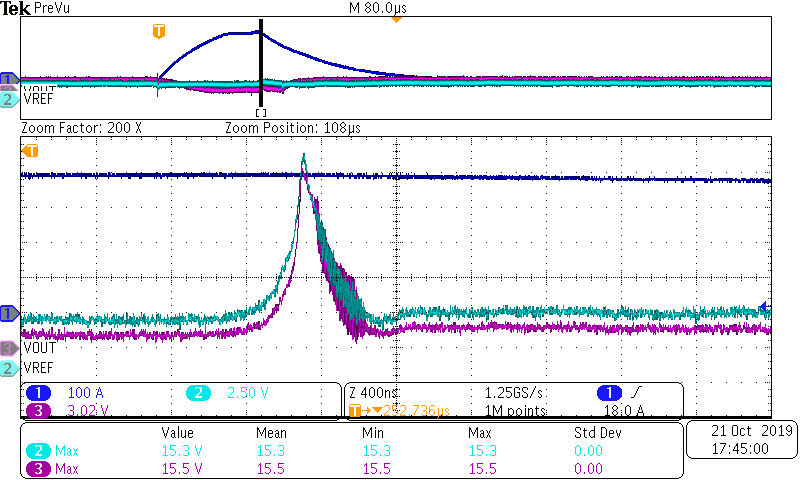

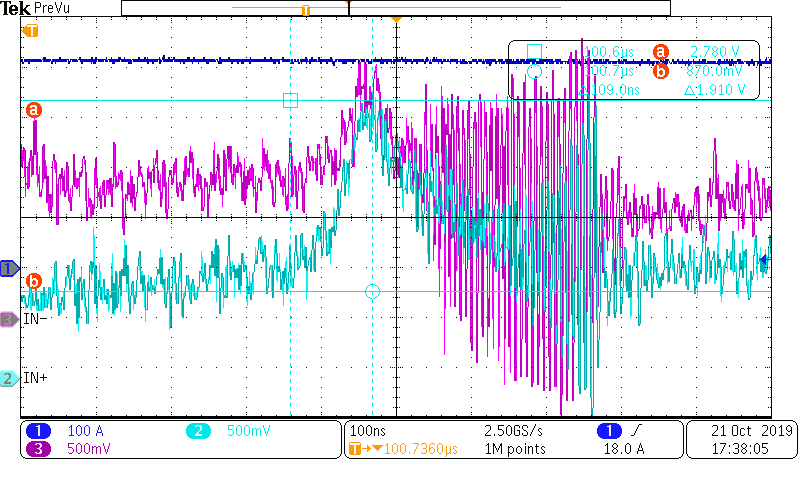

And we observed that reference voltage is changing when sudden interruption of corruption through resistance(100uOhm). Reference voltage is changing from 2.5V to 18V.

We also observed that after the IC is de-soldered & soldered it back sometimes IC is again working fine. I am suspecting during desoldering & soldering because of the high temperature during de-soldering & soldering the property of silicon might be changing.

Kindy help us to solve this issue urgently, Field issues are increasing everyday & we have deployed more than 1500 boards in the field across multiple customers.

Kindly do the needful.