Hi

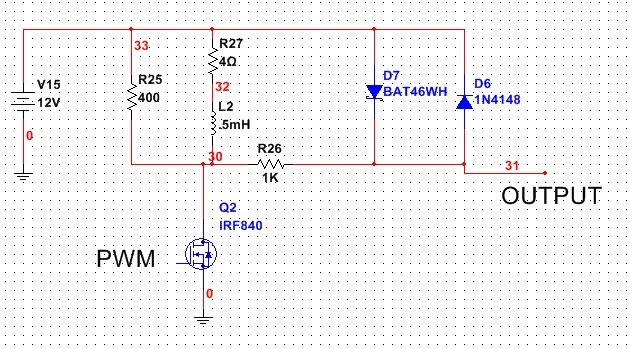

I HAVE A QUESTION ABOUT, VERY WEAK SIGNAL AMPLIFICATION.THIS SIGNAL RIDS ON A 12V DC OFFSET.

THIS SIGNAL COME FROM INDUCTIVE SENSOR.LEAST CHANGE IN SENSOR ENVIRONMENTS MAKE 20 MICRO VOLTS ON OUTPUT SENSOR.SENSOR OUTPUT SIGNAL CHANGE ALONG X AXIS AND EXPONENTIALLY CHANGED IN DIFFERENT CONSTANT TIME AND ALONG Y AXIS NOT CHANGE.

I WANT DIGITIZE THIS SIGNAL WITH 0V TO 5V ADC INPUT RANGE WITHOUT USE CAPACITOR FOR FILTER AND REMOVE DC OFFSET.

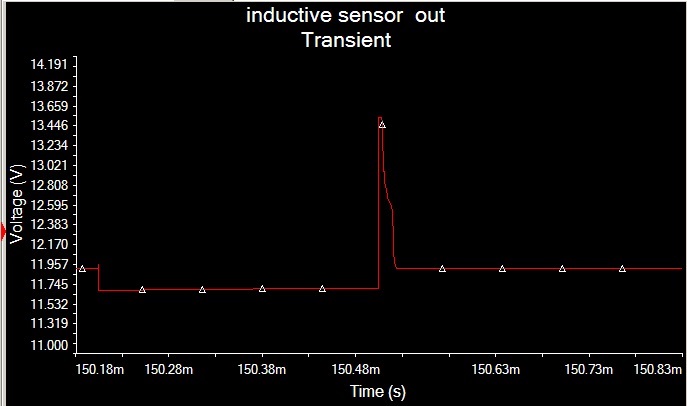

I PUT TWO PICTURE FROM SIMULATOR

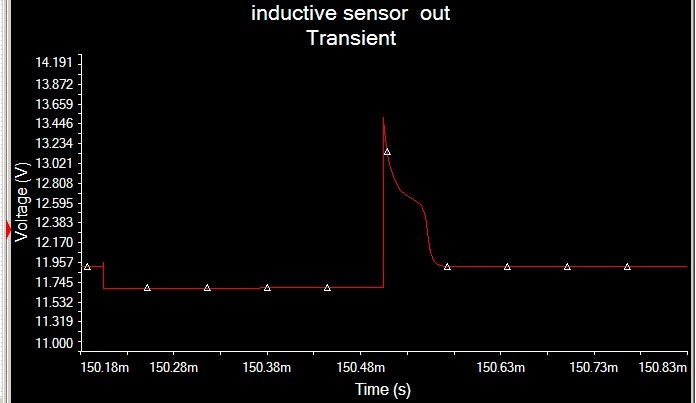

AND OTHER

THESE PICTURES SHOW OUTPUT SENSOR CHANGES .

EVERYONE CAN HELP ME FOR AMPLIFY AND CONDITIONING THIS SIGNAL??

THANKS

SINCERELY.