Dear , Sir.

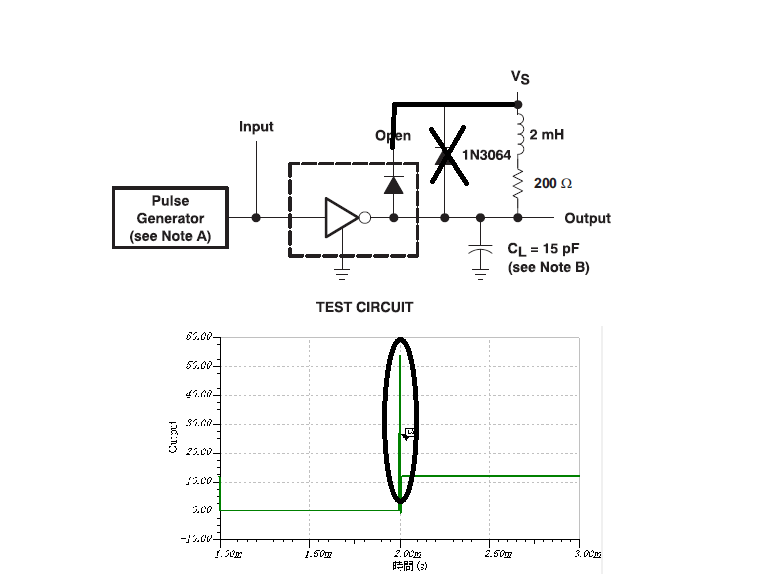

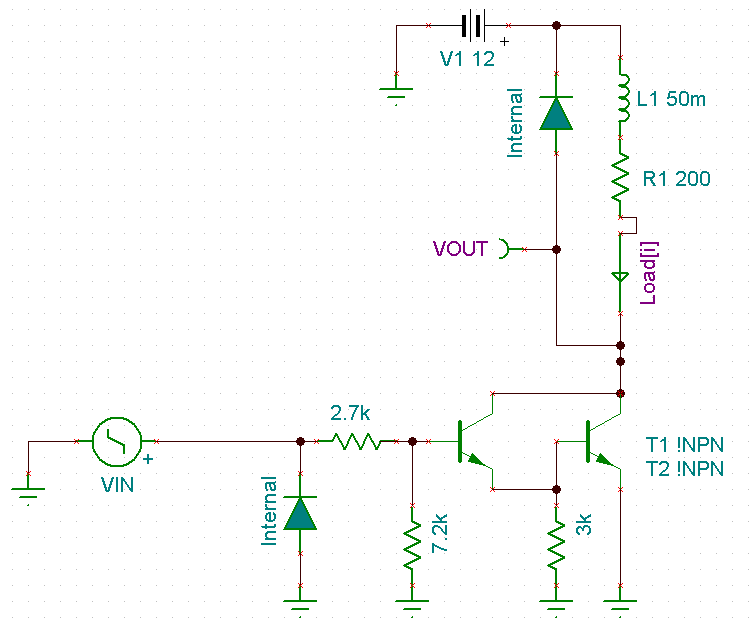

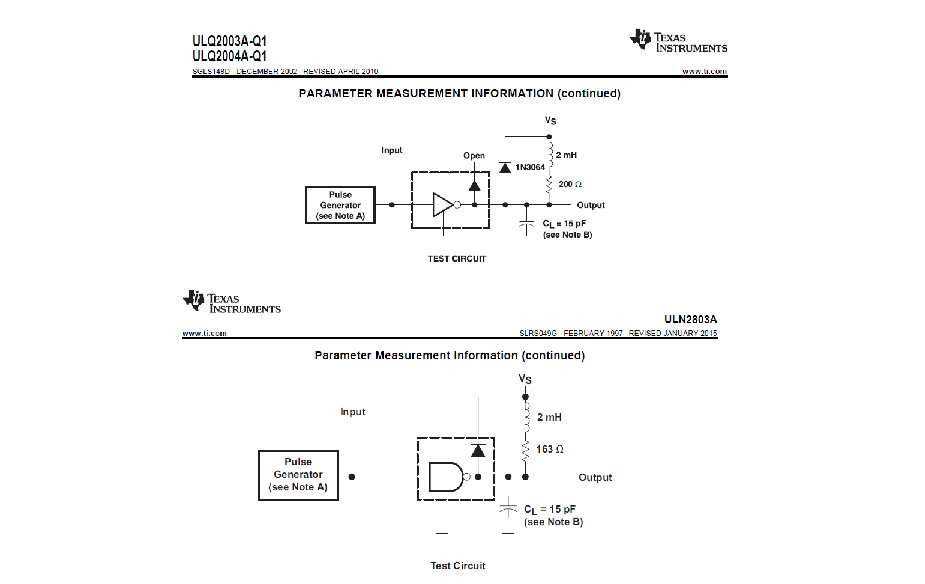

My customer want to utilize ULQ2003A-Q1 internal diode against the reverse voltage

as flywheel. I would like to confirm following 2 things in addition to the question which other person

has been asked already.

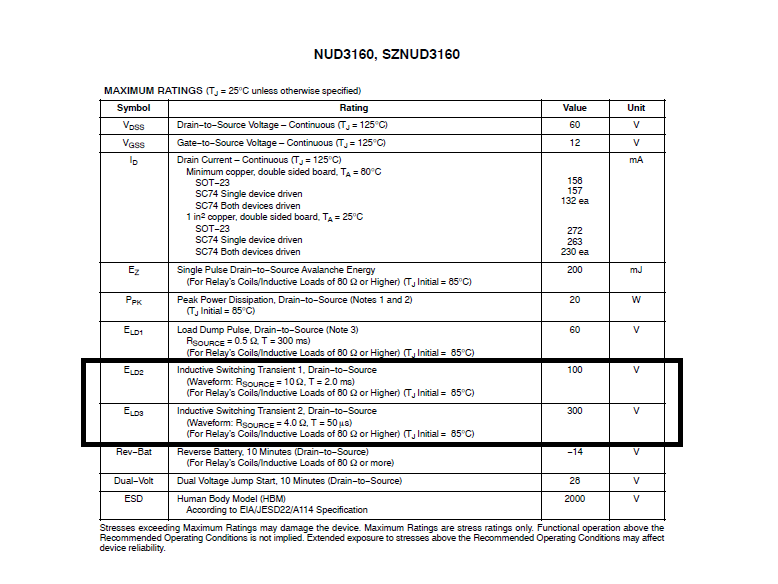

1. I undrstand the break voltage is 50V.

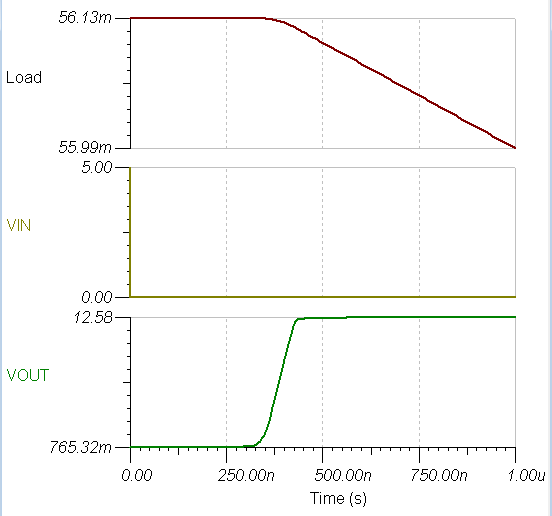

The reverse voltage duration will be quite short time.

Do you have another robustness spec specified just as transient time?

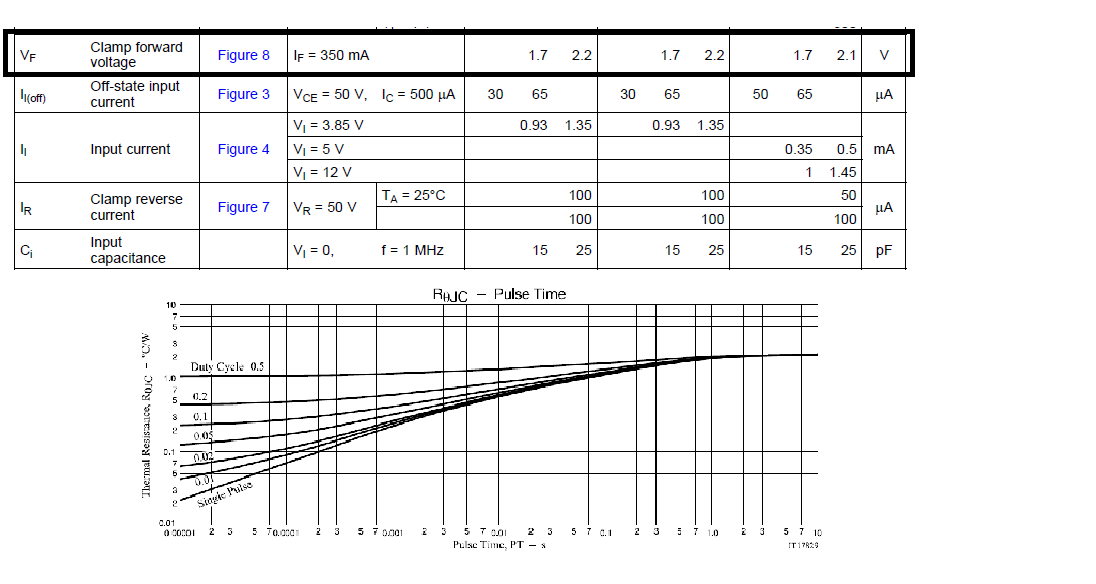

2. I understand the total thermal dissipation for Vf is significant.

The customer don't use it under PWM operation. It means that the flow is just kind of

single and short time.

Do you have the derating factor of power dissipation considering such kind of condition?

I am expecting to get your advice at this time.

Best Regrads,

H. Sakai