We're trying to use the AFE4300EVM-PDK to measure body fat percentage. We want to use a Raspberry Pi to control the AFE using SPI, and have the AFE send body fat measurements via SPI back to the Pi. We've looked at the user guide (sbas586b) and the application note (sbaa202) extensively, and couldn't find how to interface the board with an external device such as the Raspberry Pi.

- Is it possible to set up the AFE4300EVM-PDK to perform the impedance measurements without using the GUI, and solely by interfacing the board for SPI communication with the Raspberry Pi?

- We were also wondering if the ADC_DATA_RESULT register contained the final result of the impedance measurement that we should send to the Pi using SPI? If not, is there a technical reference manual that provides a full documentation of the registers we may need to use?

In the application note, we went through the steps for setting up and performing FWR bio-impedance measurements.

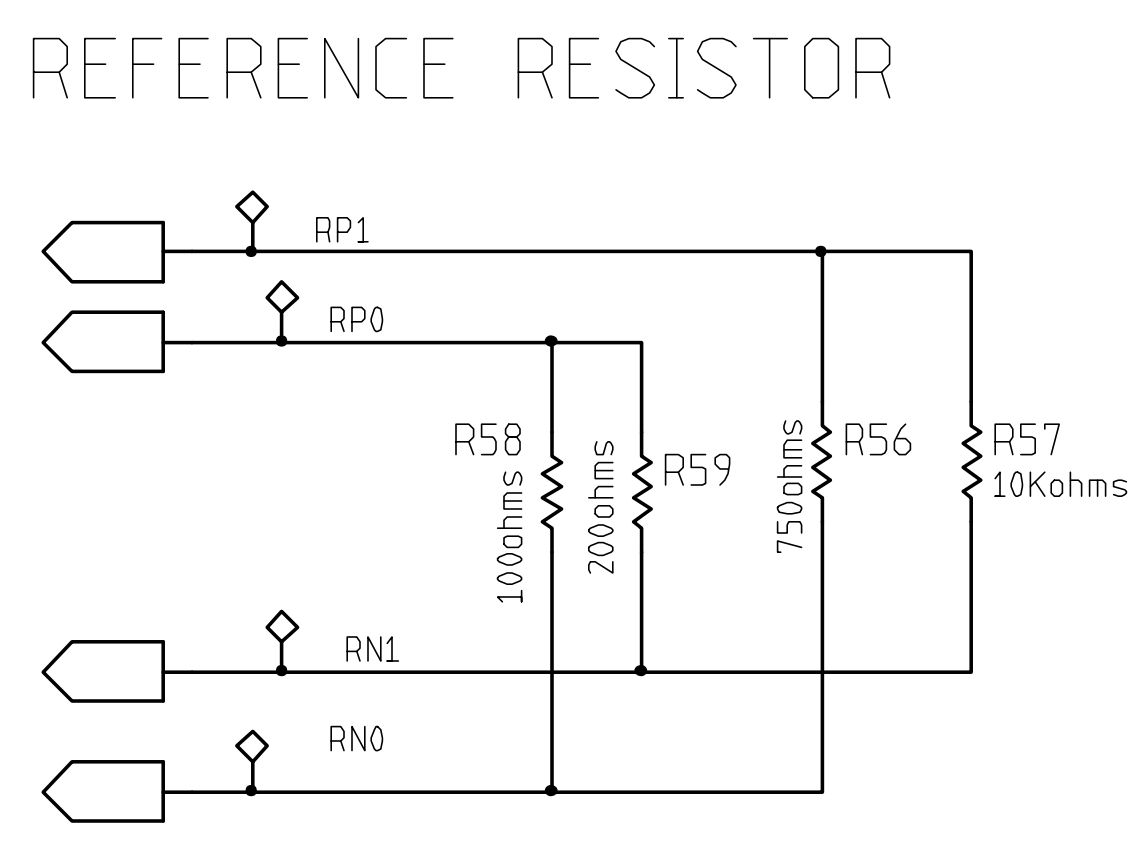

- Is it possible to calibrate the AFE for impedance measurement using resistors that are not the reference resistors (R56-59)?

- In the WriteRegisters.csv file, how does the default value of 4130 correspond to an ADC Data rate of 64sps? And how can we change this frequency value to get a different data rate?

Thank you!