Hello there,

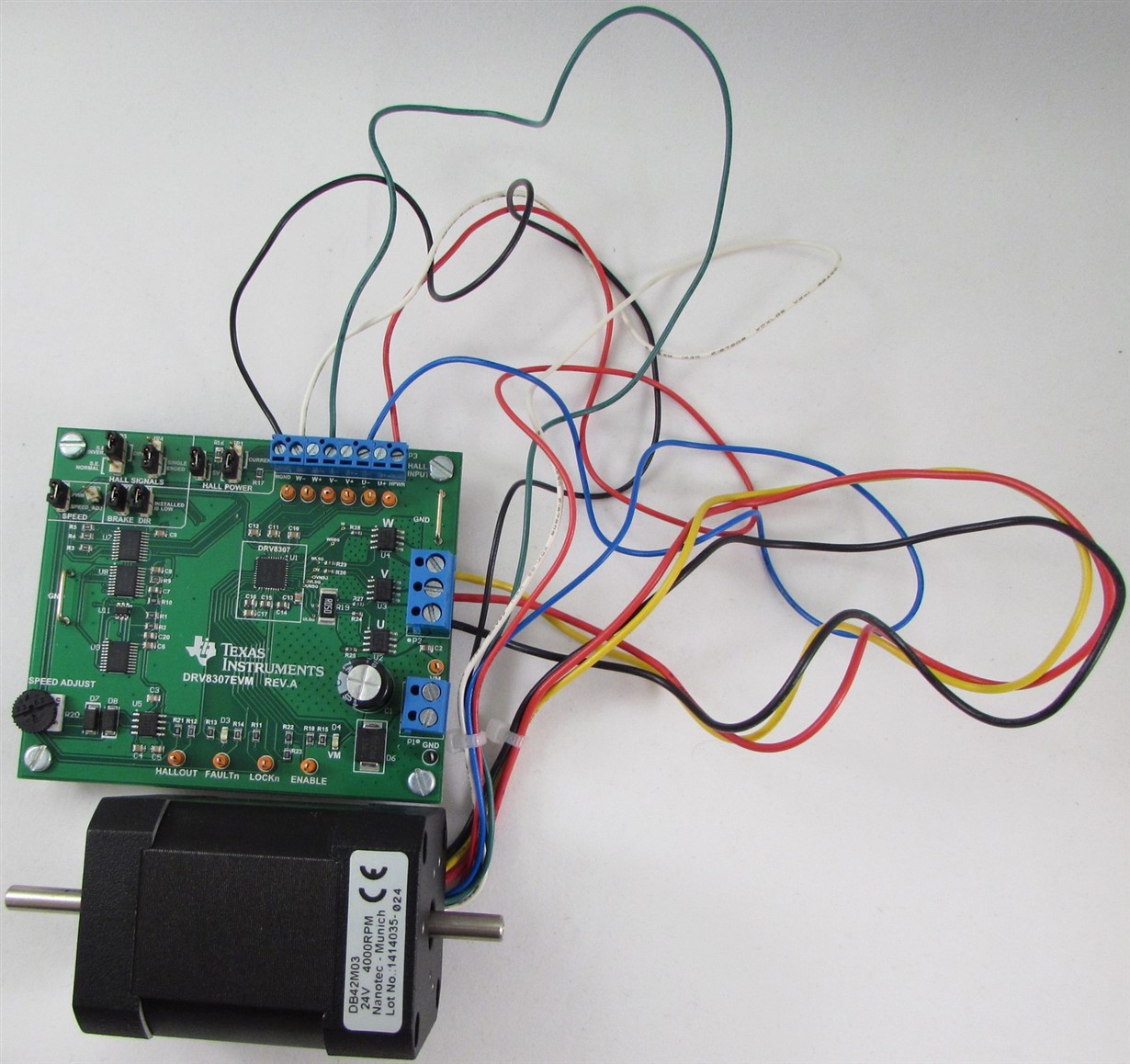

I am currently developing an application which uses DRV8307 to drive Nanotec BLDC Motor DB42M03 (link http://en.nanotec.com/products/633-db42/ ).

Everything seems to be working but one thing: When I change the Direction by connecting DIR pin to VCC the direction is indeed changed but the motor drives slowly (I drive it with 100% PWM) and "coughs".

I really dont know what I am wrong. The way I change directions and stop now are (pseudo code):

// forward DIR = LOW BRAKE = LOW ENABLE = LOW // backward DIR = HIGH BRAKE = LOW ENABLE = LOW // STOP BRAKE = HIGH ENABLE = HIGH break;

Here is a short video showing the faulty behavior. One direction spins correctly, the other one doesnt:

https://www.youtube.com/watch?v=eemiiEDQV3I

Heres the schematic of my controller, i drive it using an MCU powered with 5V:

https://dl.dropboxusercontent.com/u/14154631/mechatronic/BLDC_test_ctrl.PDF