Hi,

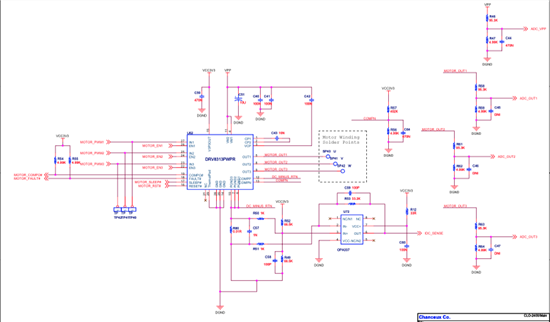

We are using DRV8313 for a new sensor-less BLDC motor with instaspin software on MSP430.

From time to time, the motor would stop and the variable (in MSP430 firmware) Fault_8313 was set to 1.

Here are my questions:

1. What conditions would cause variable Fault_8313 being set? Is there anyway to find out more information about cause of faulty conditions?

2. For now, we can only stop and start the motor to resume operation. Is there any other more graceful way to recover from such faulty conditions?

We did use a bench top power supplier to provide power to the system to reduce any possible effect from over current or over voltage.

With the same BLDC motor, we did try to set up DRV8313EVM with "TI DRV8313 EVM" PC software and the same faulty condition did occur too.