Hi,

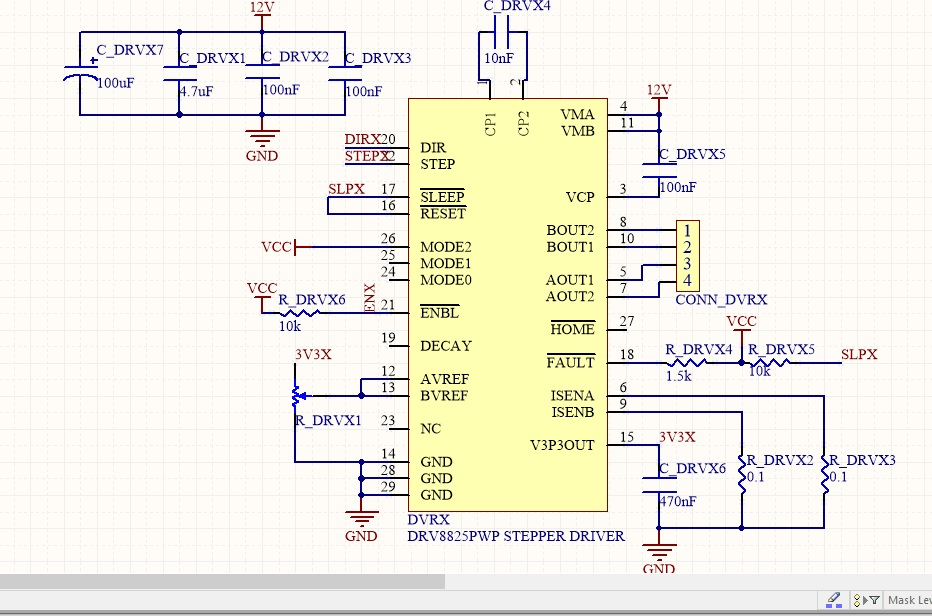

we are using drv8825 drivers for controlling NEMA 17 stepper motor. However, we have an important problem with the fault interruption which the driver internally has, because it turns down when we try to move the motor. We have read a lot of posts which talk about the same problem, but we have not still found the solution. What we have noticed:

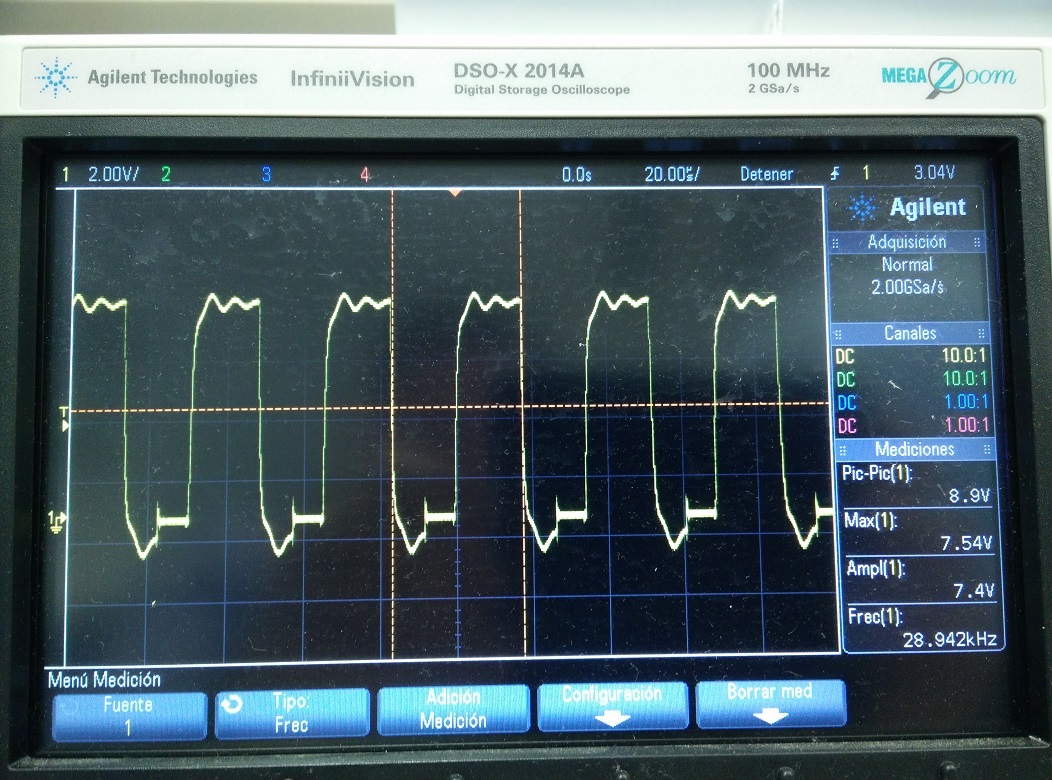

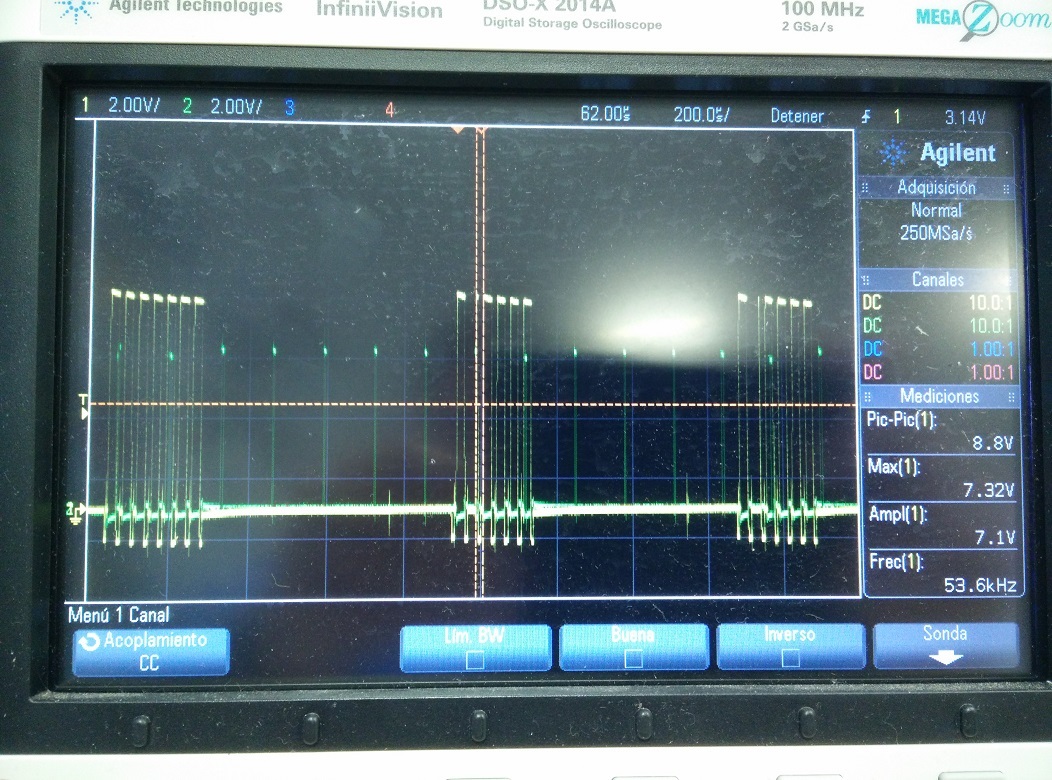

- Fault pin turns down faster with 12 V power supply than 9V.

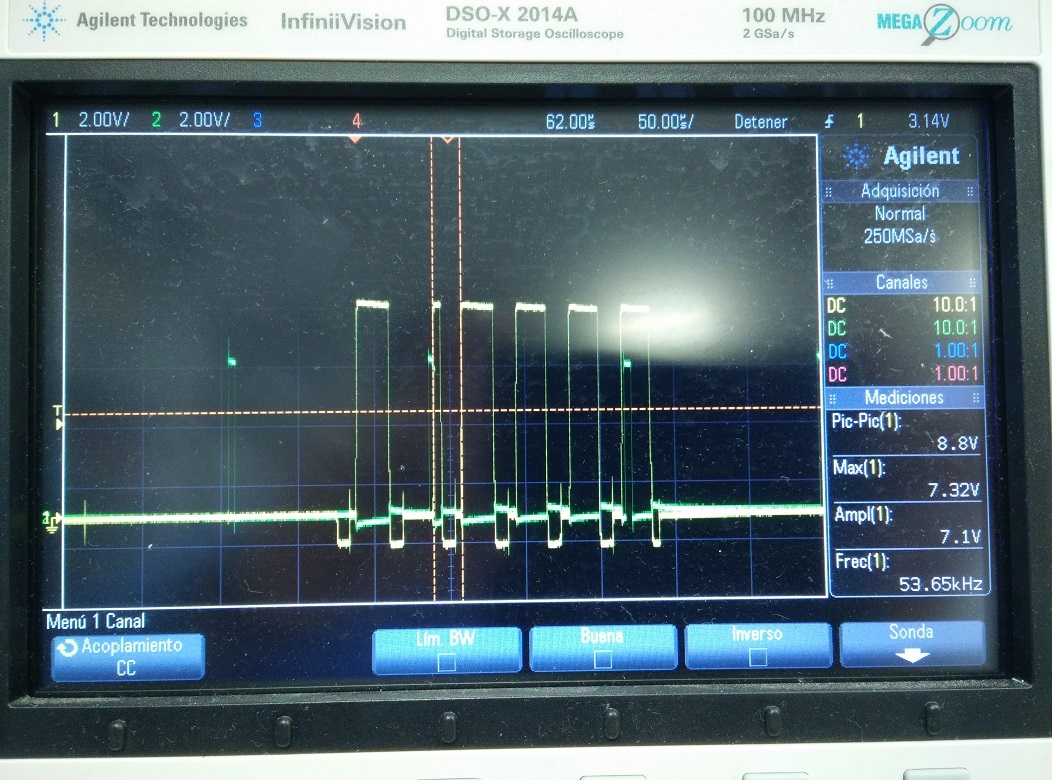

- The current which is supplied to the motors (VMA and VMB) is approximately 0.07A. This value does not change with the potenciometer.

- During some tests, the circuit has a strange behaviour. When the motor is enabled with a 12V supply, the fault pin turns down. However, when we reduce the supply until 5 or 6 V (at this voltage the driver does not work) and then fix it to 9V, the current increases, and this can be managed by the potenciometer. However, the current value does not achieve the expected value (with the reference voltage equal to 3.3V and with 0.3 Ohms sense resistors, the current was only 0.5 A instead near from 2A expected) and the stepper motor tries to move, but not correctly (a lot of little movements in the two directions). This was during some test, but now the circuit behaves as described in the point before.

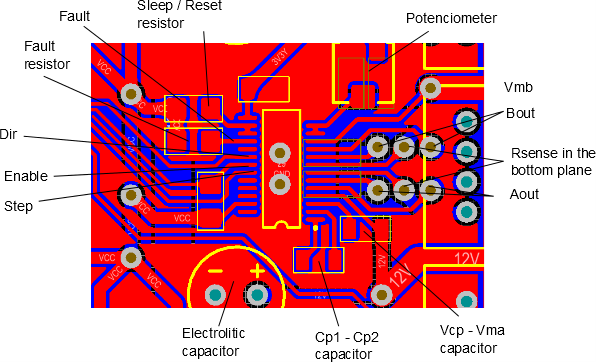

I have attached two photos: driver schematic and driver layout.

I keep waiting anxiosly for answers :)

Thank you very much and cheers,