Hello,

I am attempting to use 4 DRV8842's to drive 2, 24V 5A Stepper Motors. Since I am new to this device I set it up on a breakout board.

Rough Schematic is here:

https://upverter.com/StanTheMan/ba8f34e22c496180/TI-DRV8842-Breakout-Board/

The Sleep, Reset, I0-I4 Pins, Decay, IN1 and IN2 Pins are set as follows:

Sleep - 5VDC

RESET- 5 VDC

I0 - 5VDC

I1 - GND

I2 - 5VDC

I3 - 5VDC

I4 - GND

Decay - 5VDC

IN1 and IN2 are toggled to a PWM Waveform

I set the 3.3 directly to Vref and set the ISEN resistor to .133 Ohms for a 100% current chopping of 5 Amps.

My issue is that anytime I draw more than 1.2 Amps through the device it goes into it's fault mode.

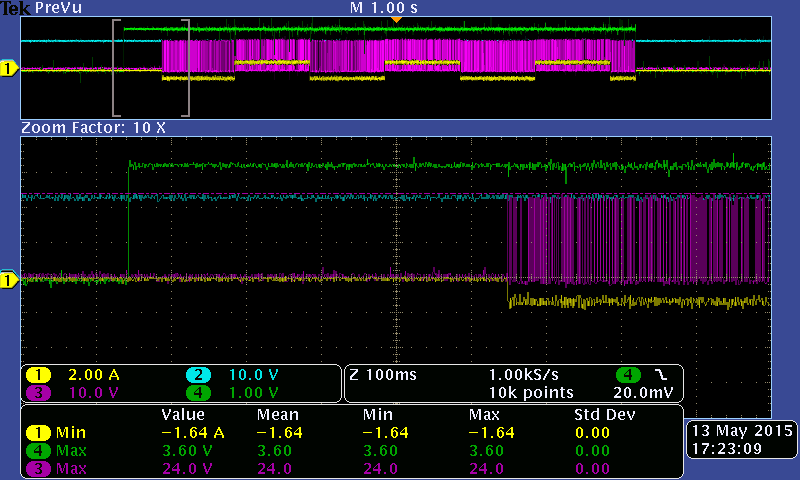

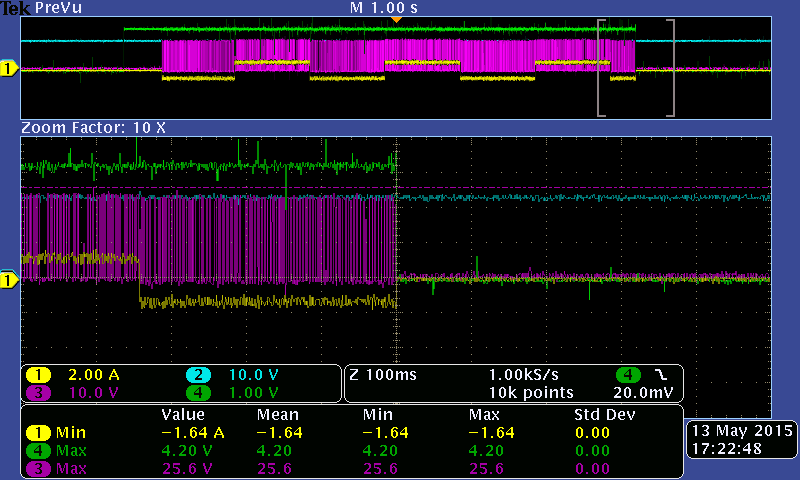

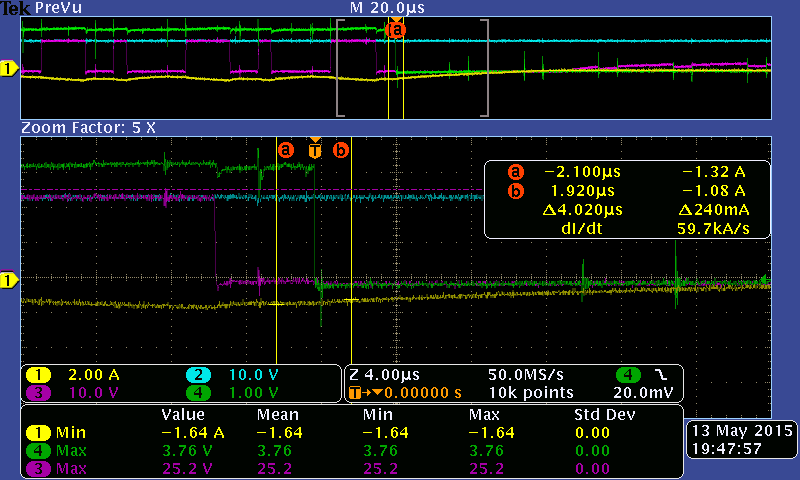

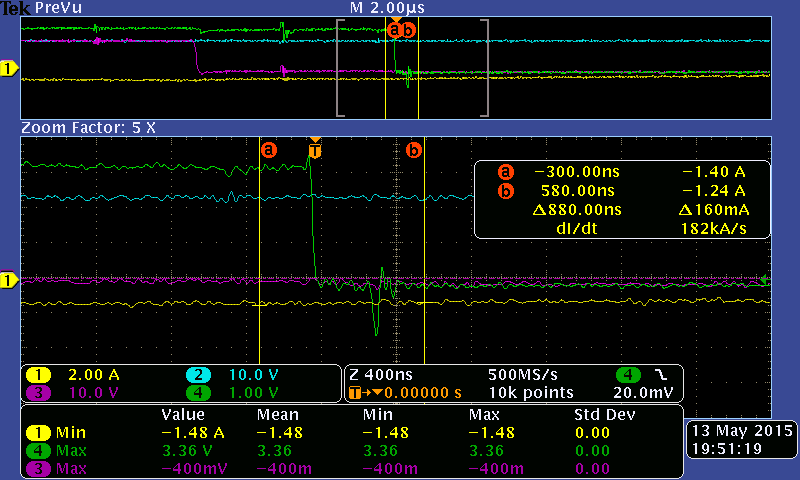

I have the issue across several devices and have confirmed the 1.2 Amps through an oscilloscope

current probe reading and verified it by checking the current drawn from my table top DC Power Supply.

I have ruled out the Under Voltage Lockout as I am supplying at least 14.4 VDC during basic testing.

(I was testing smaller individual DC Motors to see how the drive worked. So I was using 14.4 VDC)

Adjusting the PWM signal's duty cycle and the length of testing have not yet caused the fault to trip.

Also the chip stayed at a nice 29.0 Degree C while I was testing it. With that in mind I can not see how

it could be the Thermal Protection kicking in.

This only leaves me with the Over Current Protection activating at roughly 1.2 Amps.

I can set the PWM to a reasonable setting and vary the duty cycle. However once the chip

sees 1.2 Amps across it, it goes into it's fault mode and I have to reset the chip to continue

testing.

I have this issue across several chips and at this point I am stumped. Is my setup incorrect?

Could I have possibly damaged the chips while soldering them? If so is there a way I could check

for that?

Thank you for your help and time.

-Stanley