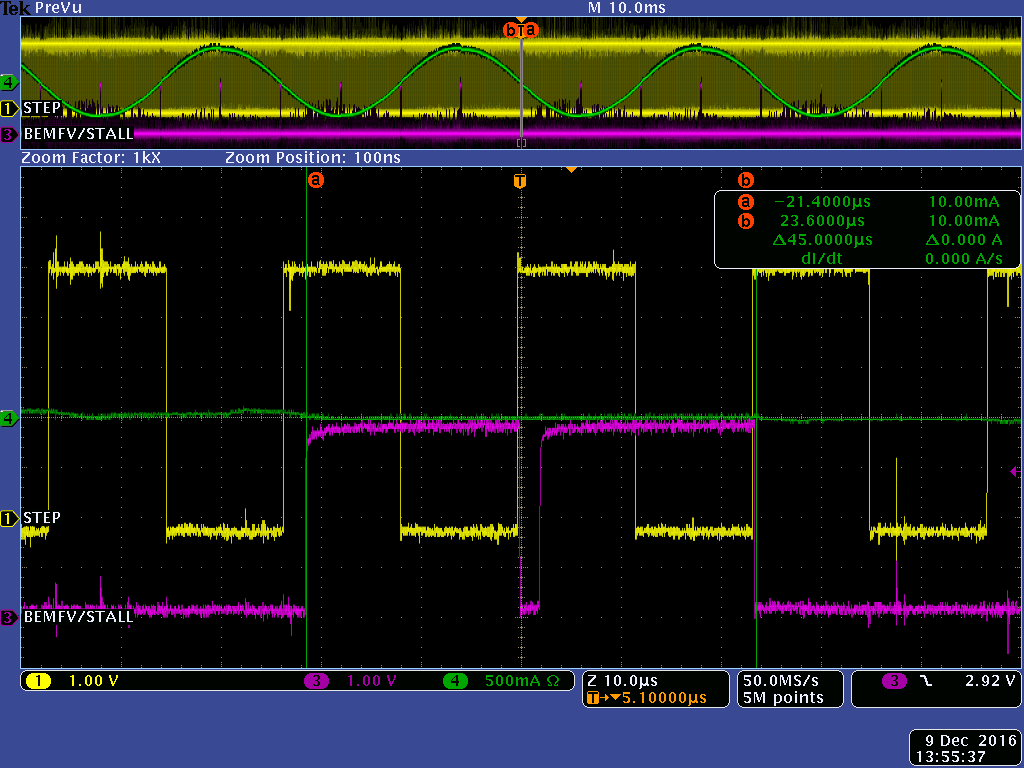

I'm seeing some strange behavior on STALLn / BEMFVn pin 19 with 256 microsteps. In my scope screen shot, purple is the STALLn/BEMFVn pin. You can see it transitions active low twice within 45us. In this example I'm running at 50 RPM which, for my motor, is 42,666 pulses per sec or 23.4us per pulse. That being said, it looks like the DRV8711 is rearming and signalling back-to-back BEMFVn measurements after the zero current step. What would cause this? Am I pushing up against the frequency limit of the DRV8711 by trying to run at 42.6kHz? I don't think I'm even close to the frequency limit because the spin guide talks about running upwards of 400kHz.

If I double the speed so it is 100 RPM, the behavior doesn't change except the two active low transitions occur in half the time. In my scope screen shot, the yellow signal is my SPI clock which is clearly staggered in-between each zero current step, so I'm convinced the double active low transition on the stall pin is not due to me reading/writing to the DRV8711 STATUS:SDTLAT bit to clear the SDT bit and STALLn / BEMFVn pin, in preparation for the next back EMF sample.

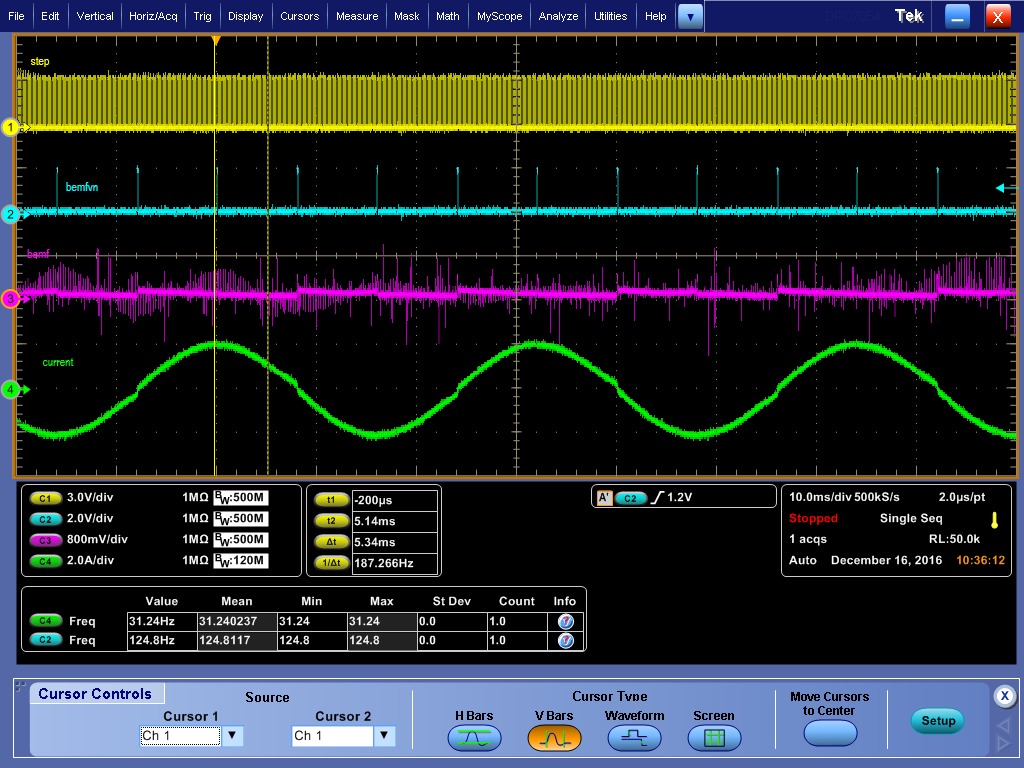

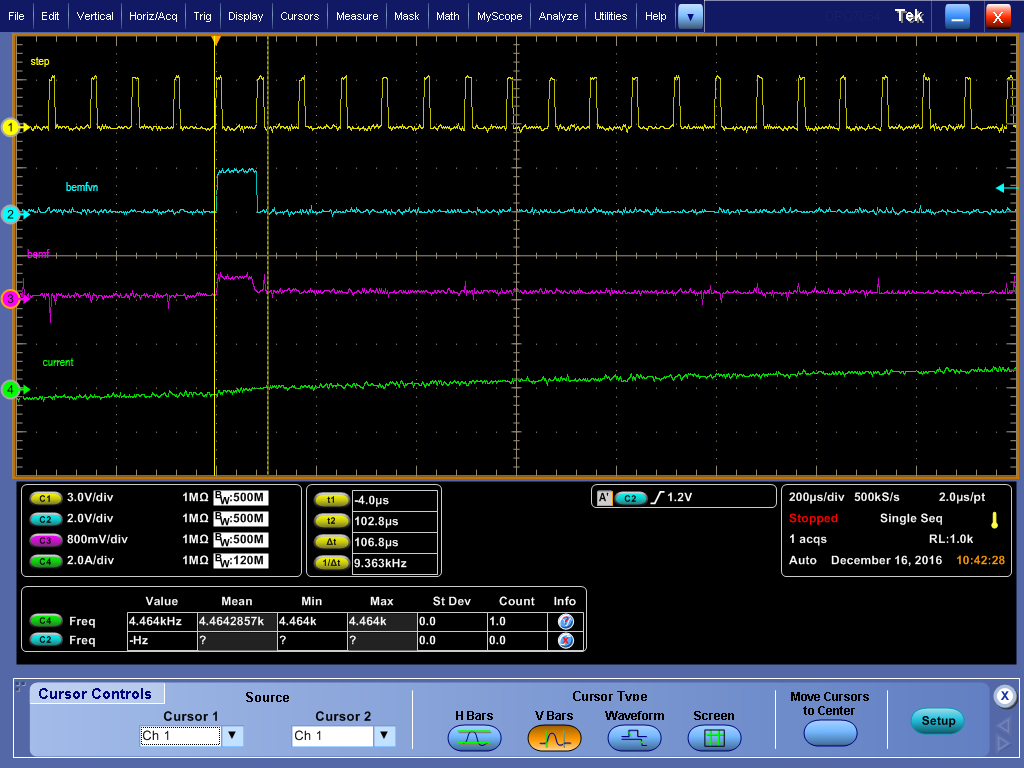

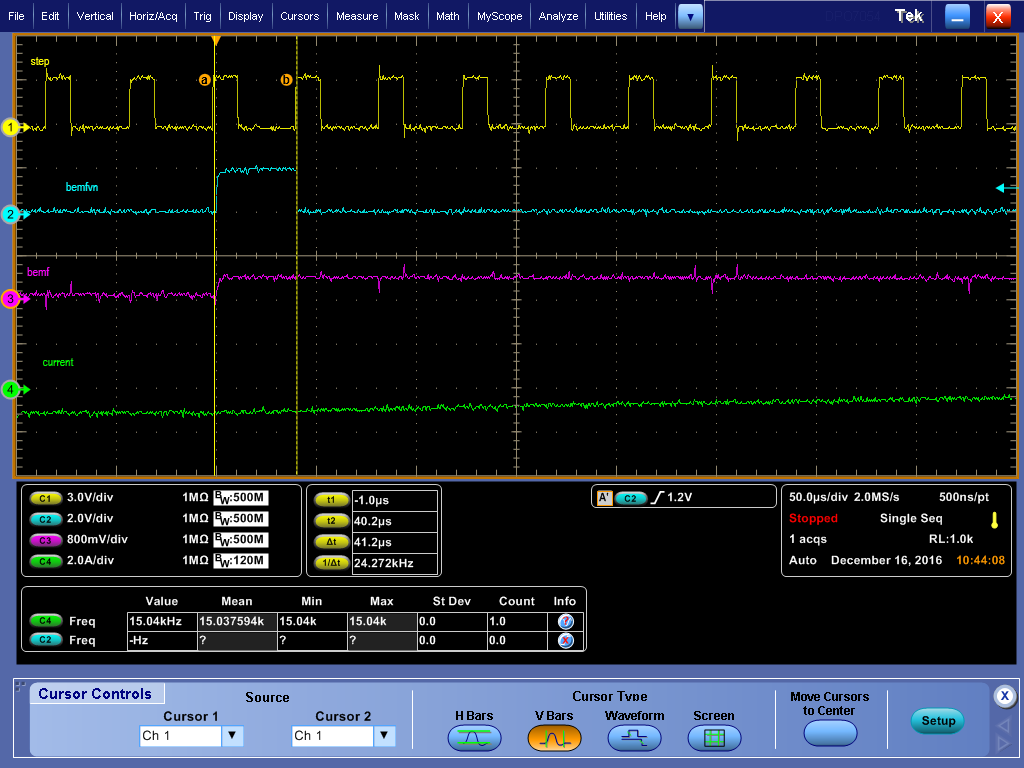

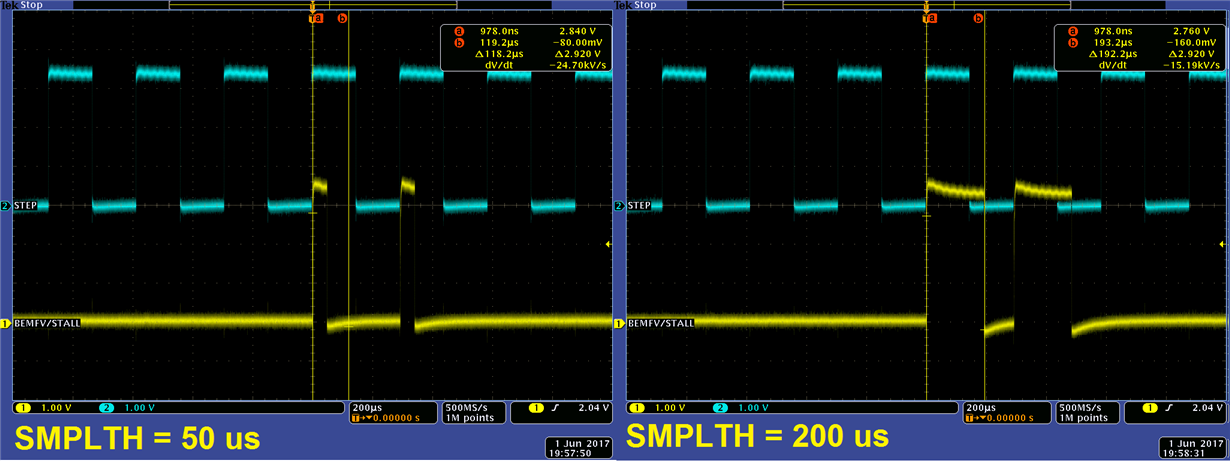

This double active low edge on the STALLn / BEMFVn pin is causing problems in my system because I'm running in external stall mode so my microcontroller is taking BEMF measurements every time it sees an active low transition. I'm using the measurements to adjust torque, so having two adjustments in one step is not ideal for my application, especially since the measurements can not be accurate since one of the active low transitions spans outside of a zero current step. If I change to 128 microsteps but keep the speed at 50RPM, I get a single active low transition at each zero current step like I would expect. Below I have include a second screen shot which shows the STALLn pin (purple signal) in relation to the STEP input (yellow signal) at 256 microsteps 50RPM.

1.) First screen shot: YELLOW = SPI Clock from Microcontroller, PURPLE = DRV8711 STALLn / BEMFVn, GREEN = Current Probe on Motor Coil

2.) Second screen shot: YELLOW = STEP input to DRV8711, PURPLE = DRV8711 STALLn / BEMFVn, GREEN = Current Probe on Motor Coil