Other Parts Discussed in Thread: DRV10975

Hi,

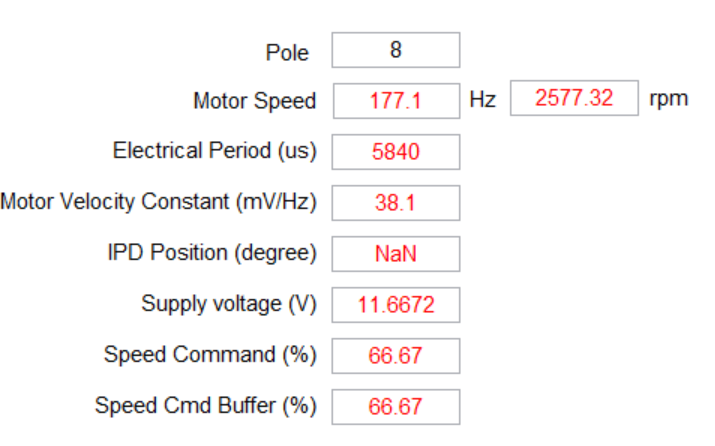

I'm having an issue with the reported speed using the DRV10975 EVM GUI. Here are my motor parameters:

Nominal Voltage: 9v

Nominal Current: 1.06A; Stall Current: 3.06A

No Load Speed; 3720RPM; Nominal Speed: 2060RPM

Phase-Phase Resistance: 2.87 ohm

Phase-Phase Inductance: 1.61mH

Kt: 56.3RPM/V = 35.8mV/HZ

Number of Pole Pairs: 4

My first question is that the automatic conversion from Hz to RPM seems wildly off. For example, I've set the Speed Control register to 100. When I poll the Motor Speed register it comes back as 62.4Hz, which according to the GUI equals 7164.18RPM. The RPM isn't even close to the actual speed (936 using a conversion factor of 15). What is the GUI using to do this conversion?

My second question is in regards to the reported Motor Speed and actual RPM. I'm comparing the actual RPM using a alternative motor controller, which is known good, and the reported speed is off by ~150RPMs. For example, the conversion factor to go from Hz to RPM should be 15, however, it dropped to 14.12 when pumping water. I verified this by comparing flow rates to the alternative motor controller. Any idea what's going on here?