Hi There

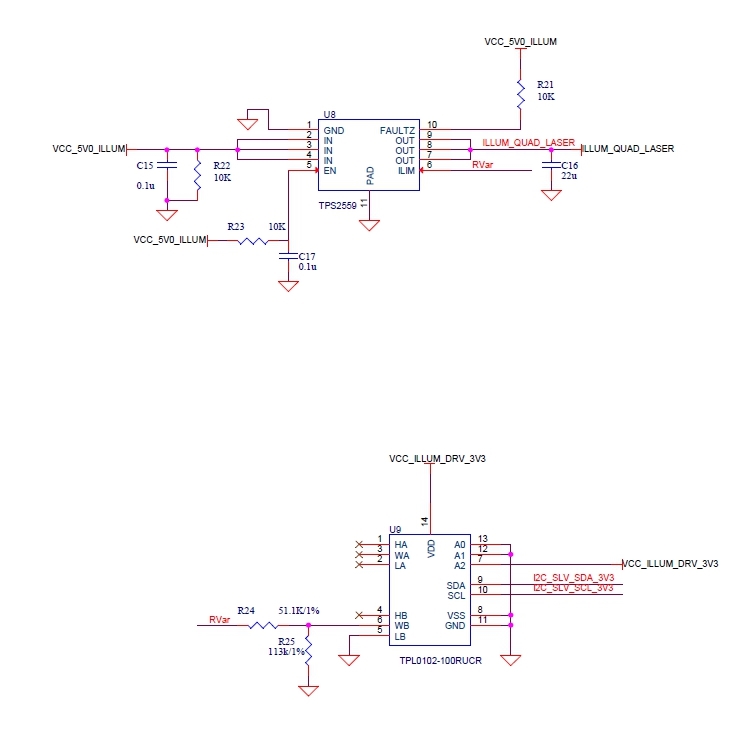

I had used TPL0102-100 as the current limit controller and my application is TOF camera. My schematic is below:

On the same PCB, I had SMT the old part before 2 years ago by sample from Avnet and can work fine. But recently, I buy new item from Mouser and it is not work after SMT on the same PCB.

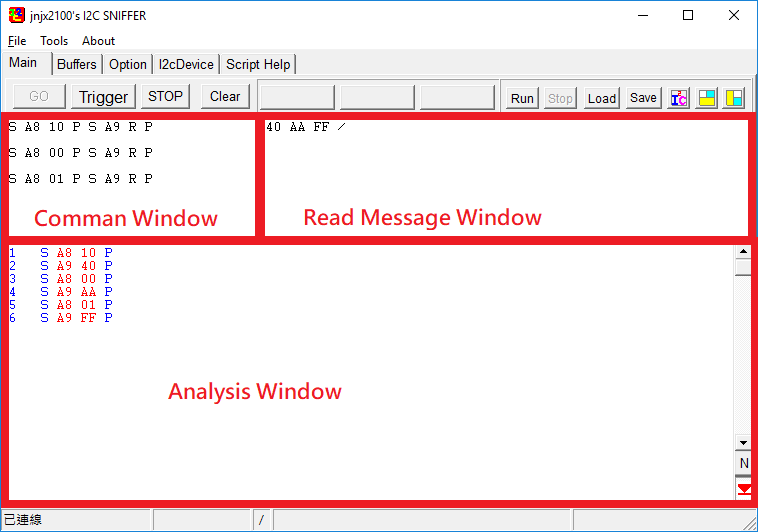

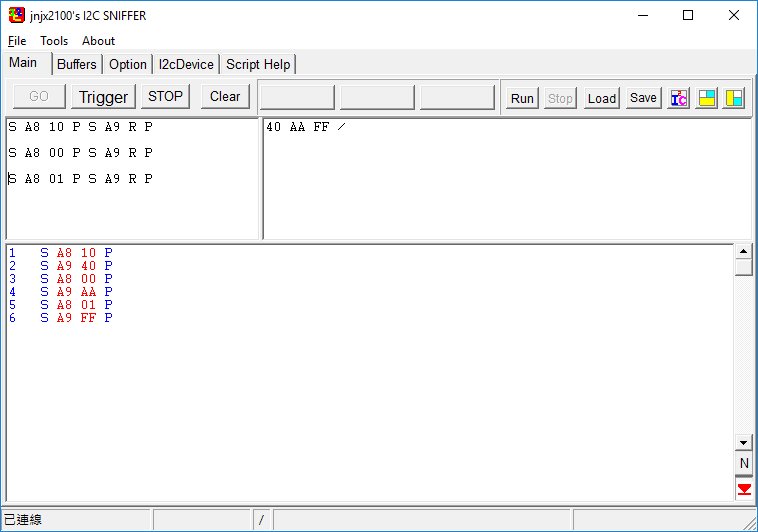

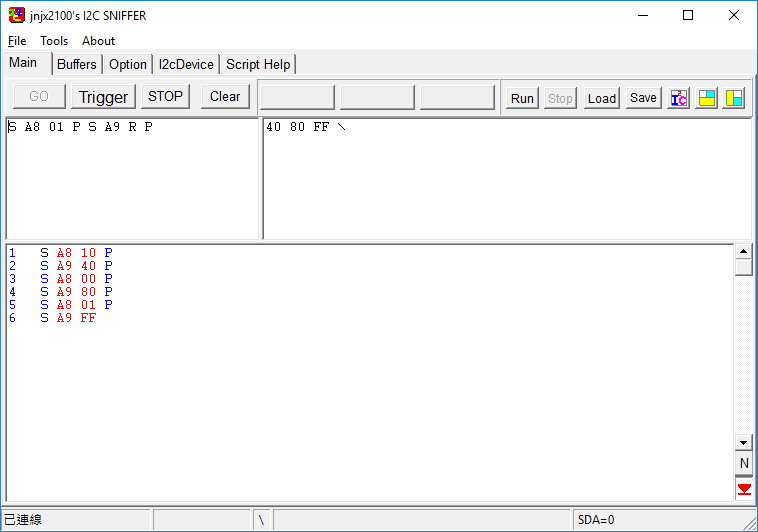

Below is parameter when module operation with Voxel viewer:

Voltage of RVar = 388mV

Voltage of WB pin in TPL0102:

Work fine item: 130mV~188mV (can control by Illumination Power in Voxel viewer(100%~50%) )

Work NG item: 193mV (can't control by Illumination Power in Voxel viewer )

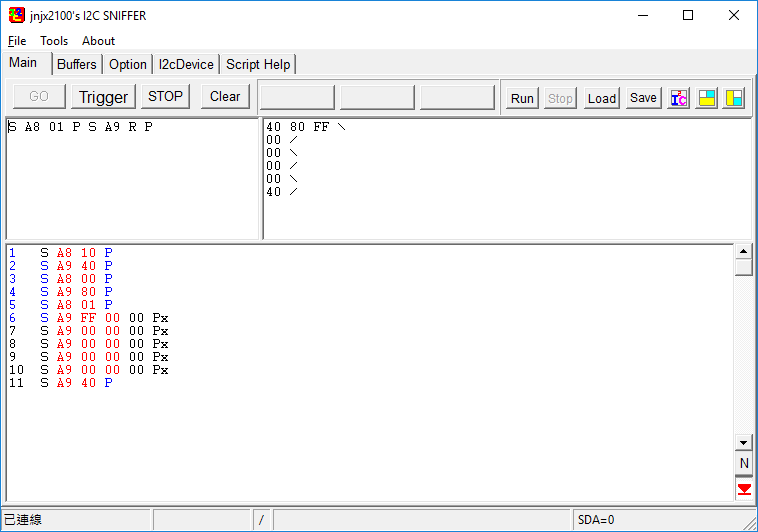

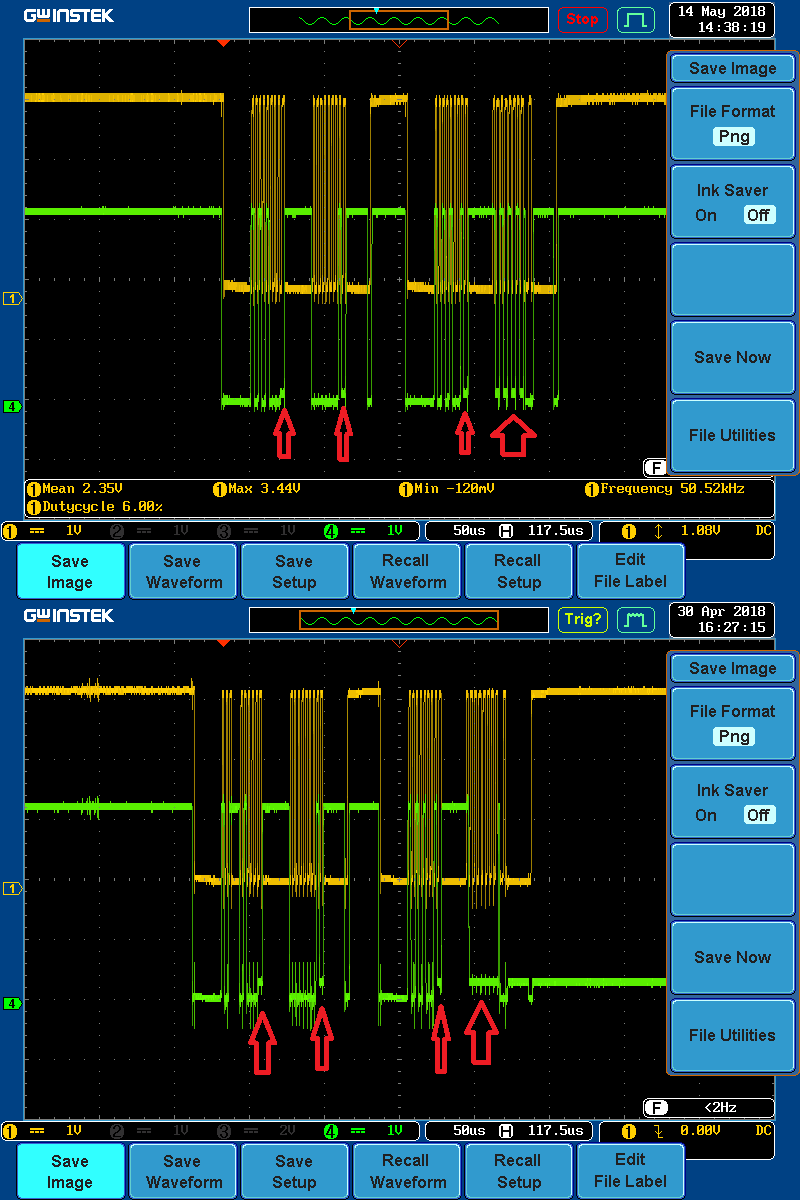

Below is scope capture the I2C pic, Red line=I2C_SLV_SCL_3V3, Green line=I2C_SLV_SDA_3V3:

Could you kindly give me support to clarify if the device defective?

Thanks.

Sincerely,

Nan