Other Parts Discussed in Thread: ADCPRO

I’m currently playing with an ADS1282EVM-PDK and I would like to design a new daughter board. I would use the same ADC, but changing the input stage and some PS and digital stuff details. This would be a prototype to validate a design concept for a future electronics, so that I handle the analog difficulties now while I let the digital design for a later stage.

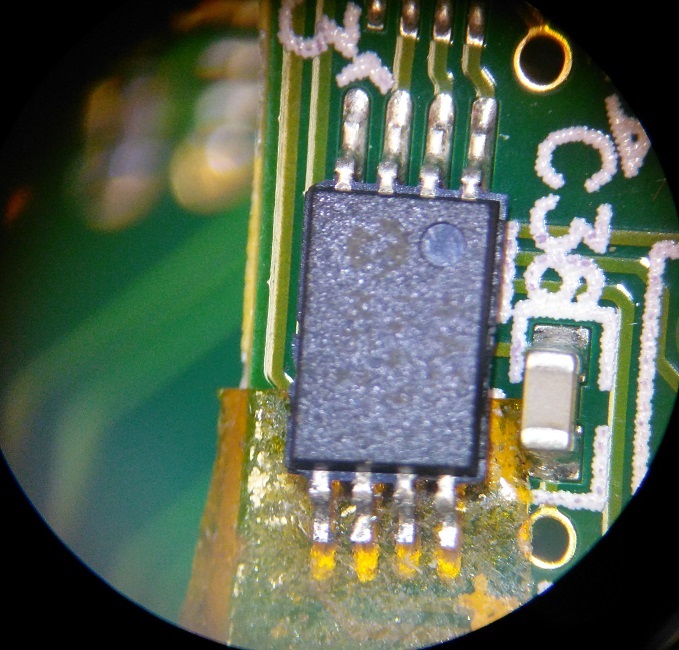

I’ve a doubt. Checking the schematics I see there is an EEPROM in the ADS1282EVM-PDK (U14). If I build my own custom daughter board using the same memory with the same connections, would that work?

In other words, is there any information in the EEPROM, when the EVM is sold, that is critical?

Of course, do not hesitate letting me know if you feel I may find other difficulties while trying to make my new daughter board.

Thanks,