Other Parts Discussed in Thread: ADS1220,

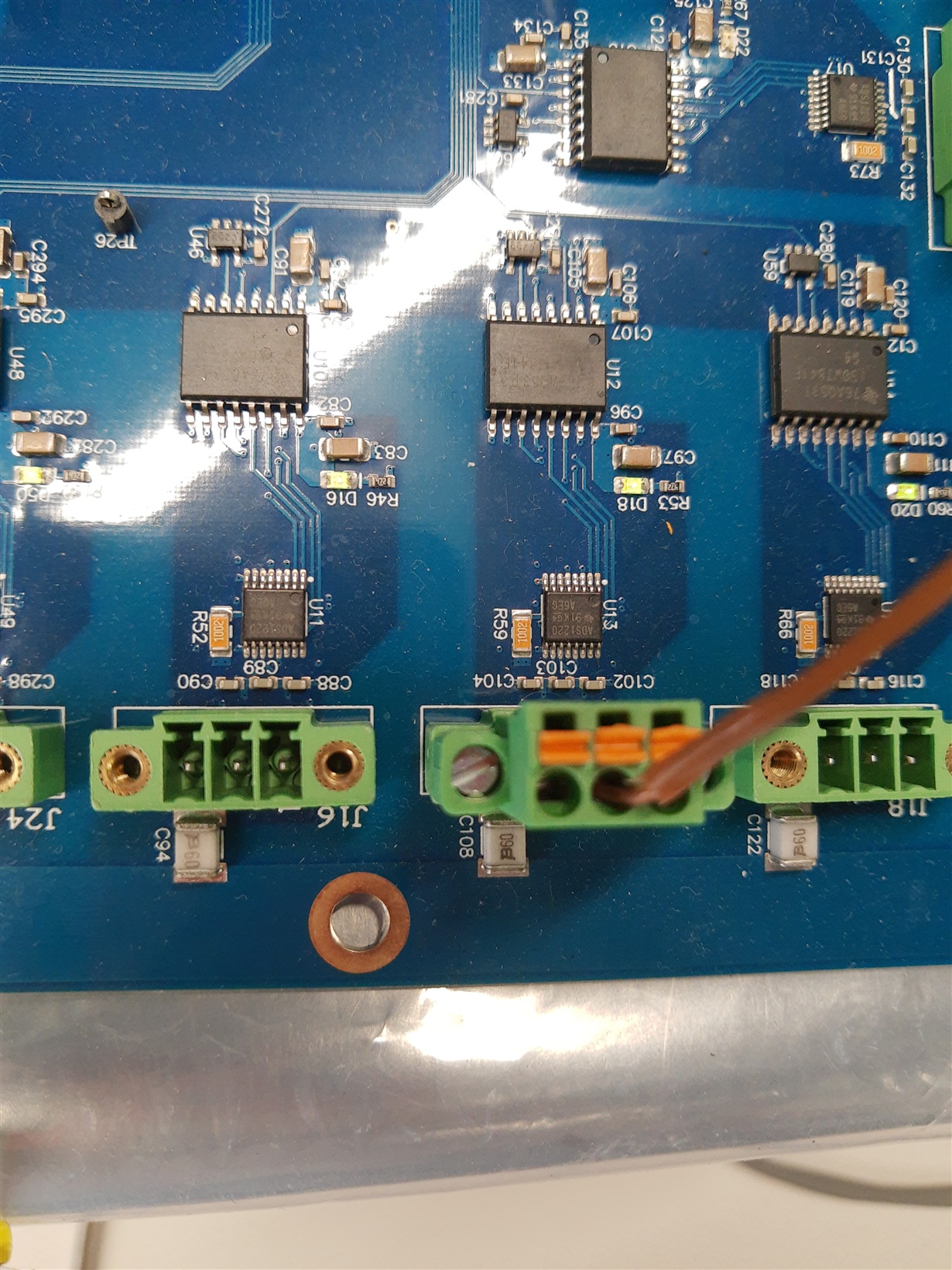

I have inherited a project using the TM4C129ENCPDTI3R to read K-type thermocouples from the ADS1220. I have some example code and will be getting the electrical schematics next week.

I'm able to read and write to ADS1220 and am curious about the values I am recieving. When I read the internal temperature sensor, I get a value of 0x11652e, that is then bit shifted by 10 values and that number is multiplied by 0.03125 from page 31 of SBAS535C document. I get a value of ~35 degrees C.

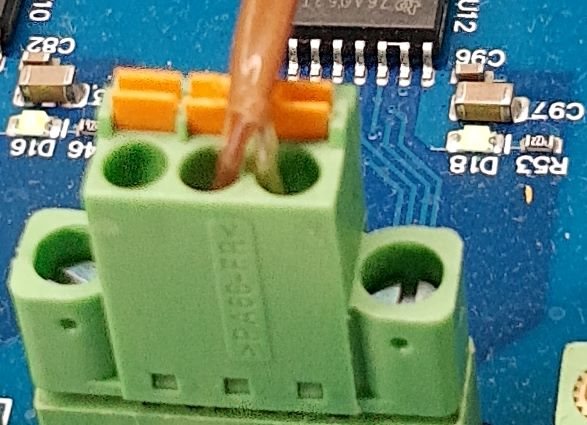

I then attach a k-type thermocouple calibrator to the input and check to see when the ADS1220 is reading around 0, which is when the calibrator outputs 24.6 degrees C.

Is my math correct for the Internal temperature sensor?