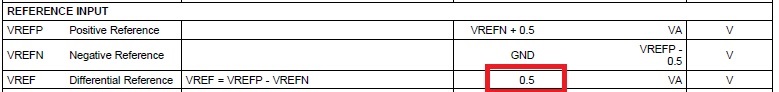

I would like to measure an RTD every period of time (from 1 min to 1 hour) and set the LMP90078 to “Power-Down” mode between measurements.

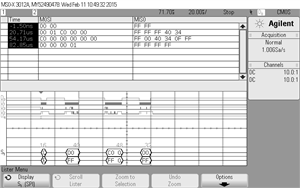

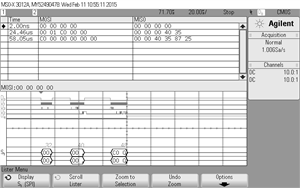

I’ve got the device to measure in “Single channel, Continues scan” but every time I’m setting in to “Active mode” it will wake up but after reading the conversion it fails on CRC check.

My goal is to get the following sequence every minute:

Set to Active mode

Read sample

Set to Power-Down

I’ve attached my register settings. And my circuit is as described in the datasheet figure 65.