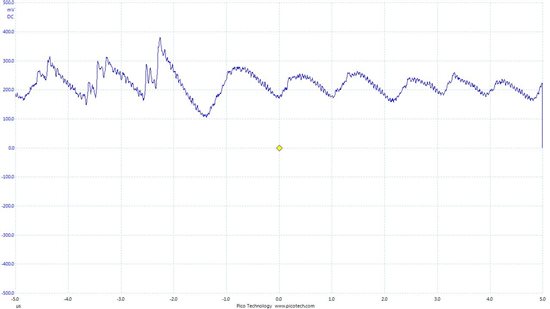

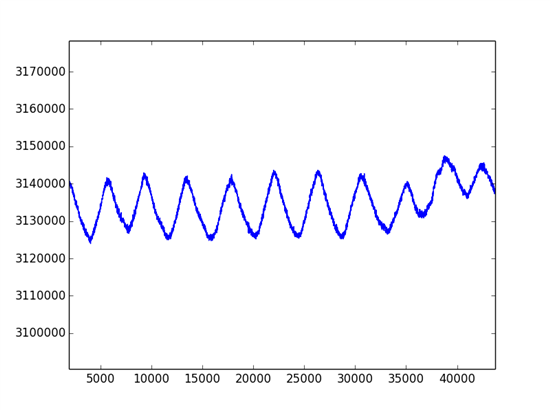

I am developing a respiratory monitoring application using the LDC1000 and an off-the-shelf respiratory inductive plethysmography band. The band contains a coil of wire. The concept of the application is to measure the inductance of the band as the chest or abdomen cause the belt to expand/contract during breathing. The reasons I'm not using the off-the-shelf driver circuit for the band is 1) they're expensive; and 2) they include filters that I don't want to use.

I have managed to get the system working somewhat but it isn't very stable. In troubleshooting I have a few questions that I can't work out from the data sheet:

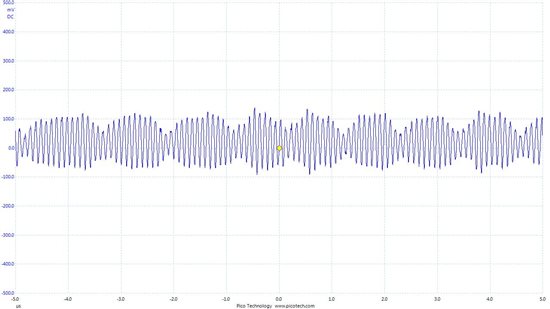

1) Output data rate: I am using the interrupt pin on the LDC to as a data ready pin. When I measure the output data rate on this interrupt pin I have found the data rate to be exactly 1/4 of the data rate that the data sheet specifies. i.e. when I set the response time to 6144, I get a data rate that corresponds to a response time of 1536. Has anyone else observed this?

2) Oscillation frequency of the LDC. What is the difference of changing the oscillation frequency and how do you select an oscillation frequency for a given application? I have an output from the LDC when I use an oscillation of 1V but if I increase it to 2v or 4v, I don't get an output from the LDC.

3) Filter capacitor. i) Does the filter capacitor effect the measurement of inductance or does it only effect the proximity output? ii) I understand how to choose the filter capacitor from the data sheet but I can not get the CFB pin to an amplitude of 1 V no matter how small I make the filter capacitor.

4) Tank capacitor. Would the tank capacitor (I am using a ceramic disc capacitor) effect the series resistance of the LC tank circuit? According to the data sheet I have for the belt I'm using the series resistance should be 2.5Ω (I have confirmed this using a multimeter). However, when I work back from the proximity output of the LDC, I calculate the series resistance to be ~30Ω. This is a problem as to keep the resonant impedance within the range of the LDC, I have to use a LC tank capacitor that creates a resonant frequency of 10MHz (well above the recommended 5MHz limit of the LDC). I know I could add an inductor in series with the respiratory belt, but I'd like to understand why I'm finding such a high series resistance. If it was closer to the belts data sheet then I could get the system working without an extra inductor.

I'm a mechanical engineer by background so excuse me if any of the questions are obvious. Any help would be very much appreciated, I have been trying for weeks trying to understand how to get this chip working in this application!