Hi everybody

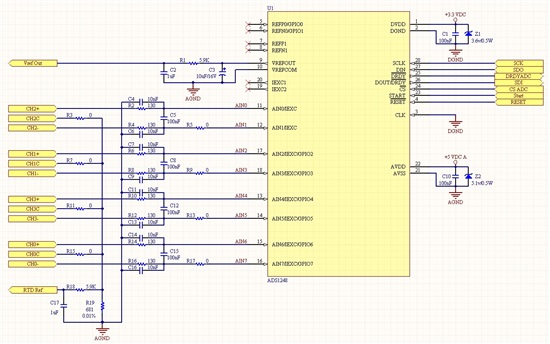

Recently I designed a board that measure Type K & J of TCs. My schematic is according to below figure. and sample rate is 5 S/S.

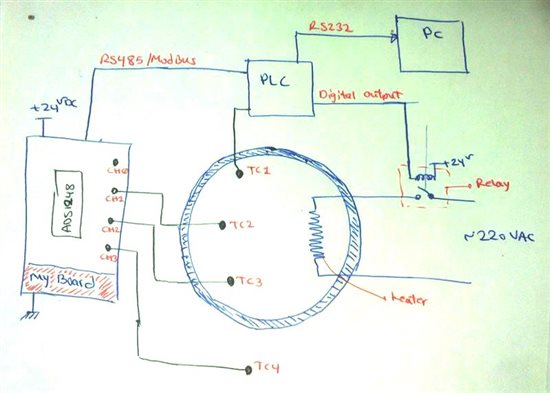

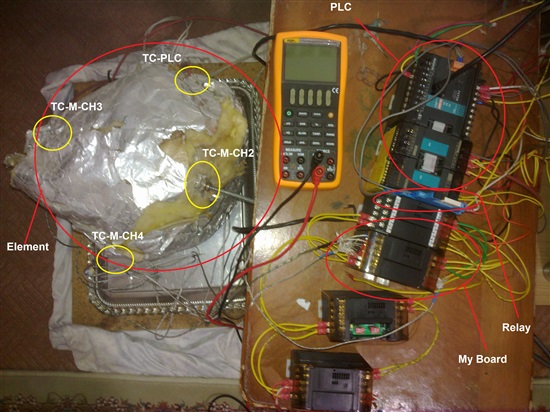

For testing of the operation of my board I use the below configuration.

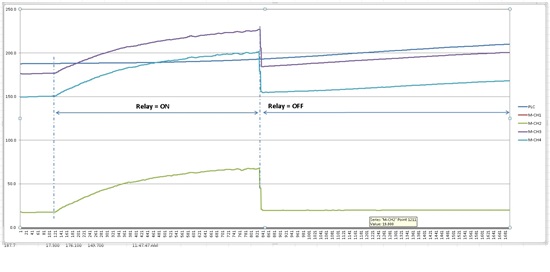

the result is according to the below figures

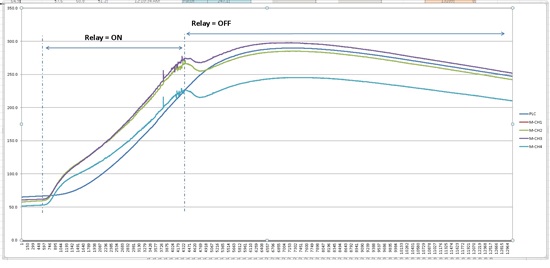

also if I put TC4 to the chamber

as you see on the above figures when we turn on the relay we have an offset and when we turn off the relay the offset is removed!!!

I do my best and test everything but I can't do anything.

can anybody help me??? please

best regard

Mahdi