Hello Bob;

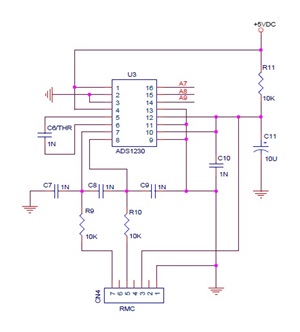

I am having some issues in the power section of ADS1230. The resistor R11 is 1E - 0805 package and C11 is 470uf /16V capacitor. The R11 resistor is burn out (dead) in most cases when i connect the loadcell, is this problem due to power rating of the resistor.

Secondly is there any special no clean flux must be used for better result. Will RF800 liquid flux be suitable, its low solid no clean flux (5% solid).

Thank You