Hi all,

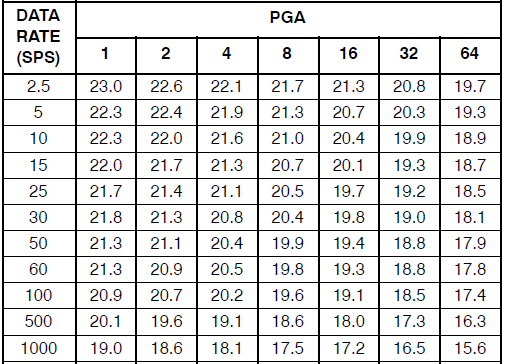

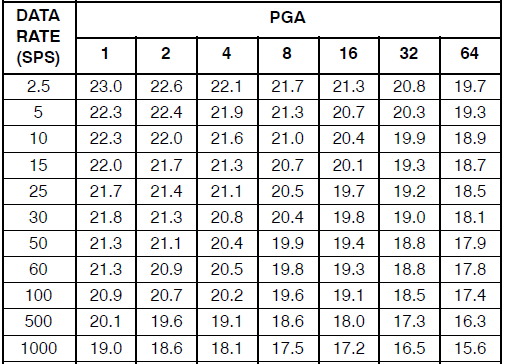

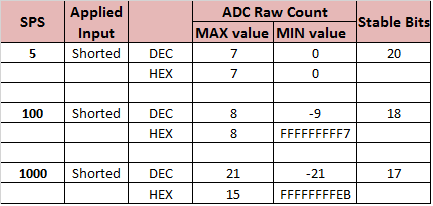

I am using ADS1256 for my application.When i short the ADC input (AIN0 and AIN1) at 1000 SPS I am getting stability of only 17 bits. According to datasheet it should be 19 bits.

My supply is AVDD = +5.0 V , DVDD = +3.3 V and VREF = 1.2 V. What should be the issue for this unstability?

Waiting for yor reply.