Hello,

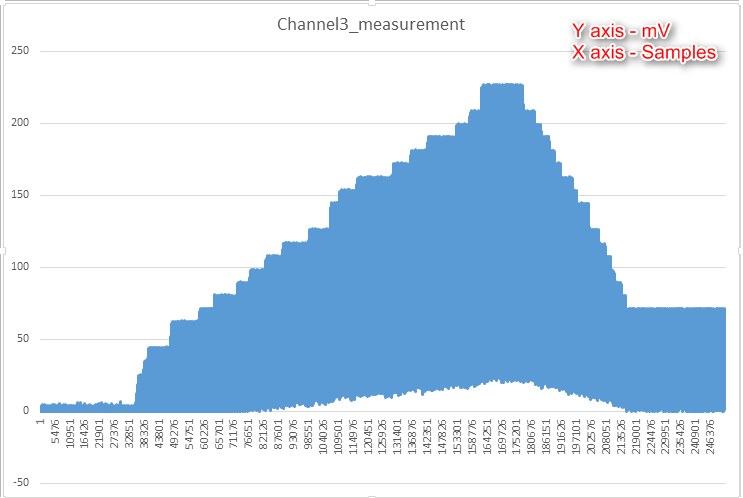

I am using ADS1296 to measure the DC output voltage from the Agilent U8002A single output DC power supply.

I have configured the ADS with the following,

Data rate :- 500 sps

Mode :- High Resolution mode

Gain :- 12

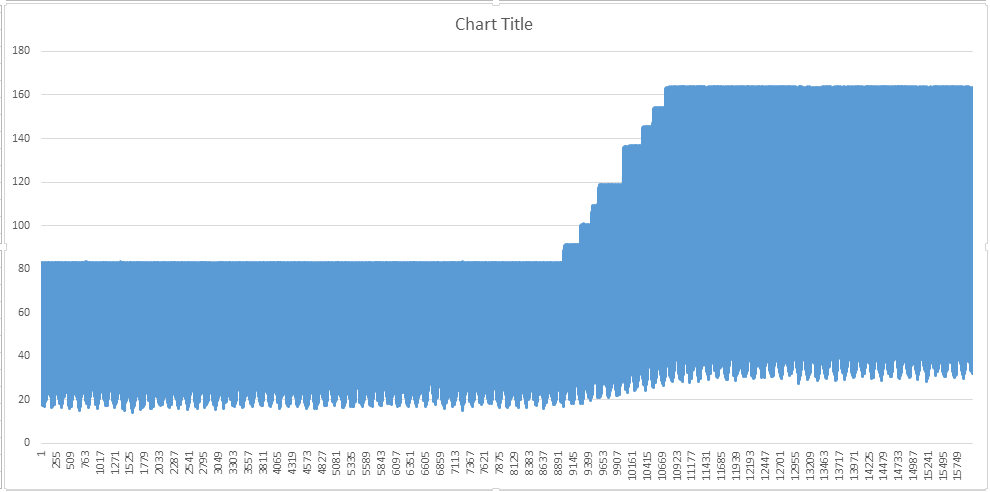

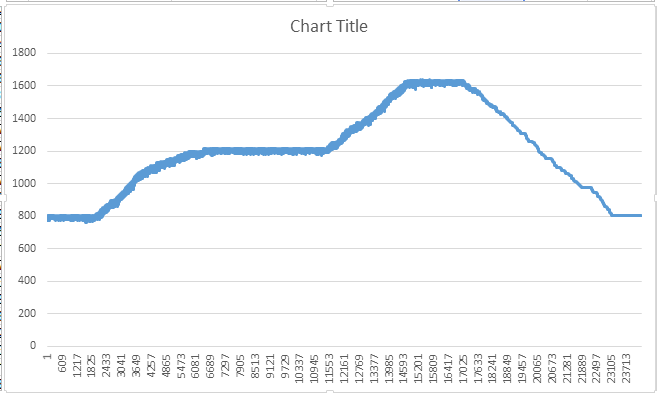

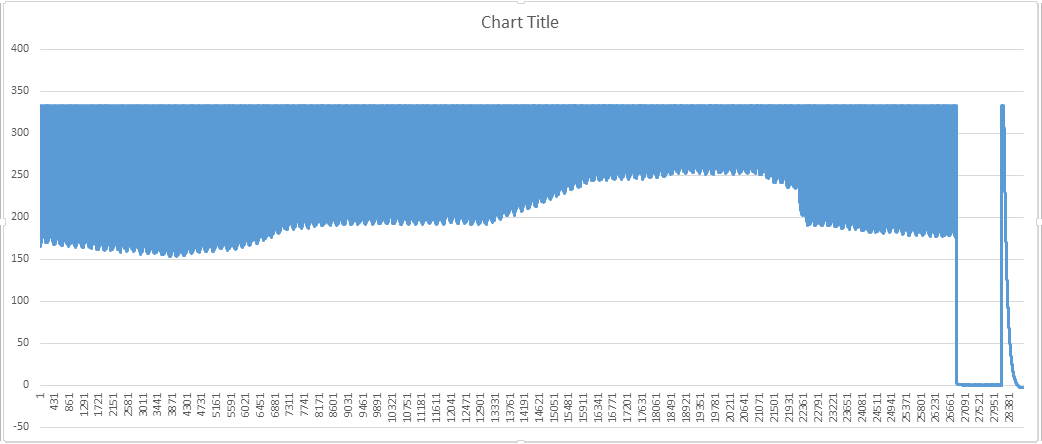

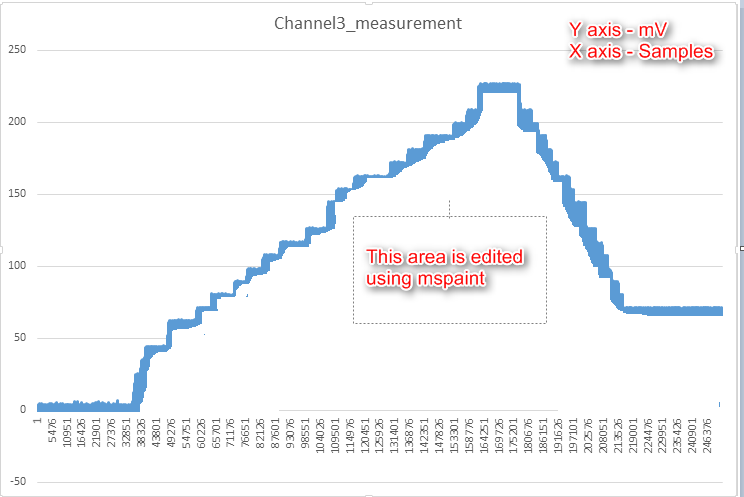

The input voltage was set to 80mV then it was slowly increased from 80mV till 160mV.

The measured values are then plotted in excel sheet. I was surprised with the plotted values.

I wanted to know why there is a fall in value, instead of the value stays constant?

Please comment.

Thanks,

Nimi