Dear All,

I have an issue with my ADS 1248 circuit. I have a simple ratiometric circuit, exactly like a 4 wire RTD setup. 1 mA flows through IEXC1 with 1.2kohm across REFP0 and REFN0. I have put a 430 ohm resistor across AIN0 (positive) and AIN1 (negative).

The controller that I am using is an Arduino Uno with the Flydroid ADS1248 library. I can get all the registers to read. Using the external ref test, the ADS reads about 1.21V across REFP0 and REFN0, which is expected.

I am using a PGA gain of 2.

The measurement precision is >0.05% if I take the result when the device is switched on and sampling, the 24bit value is ~ 5BD3E7. The issue I have is that day to day or when the device is put off and on for an hour or so, the reading of the ADC has a large difference, in the order of 1%.

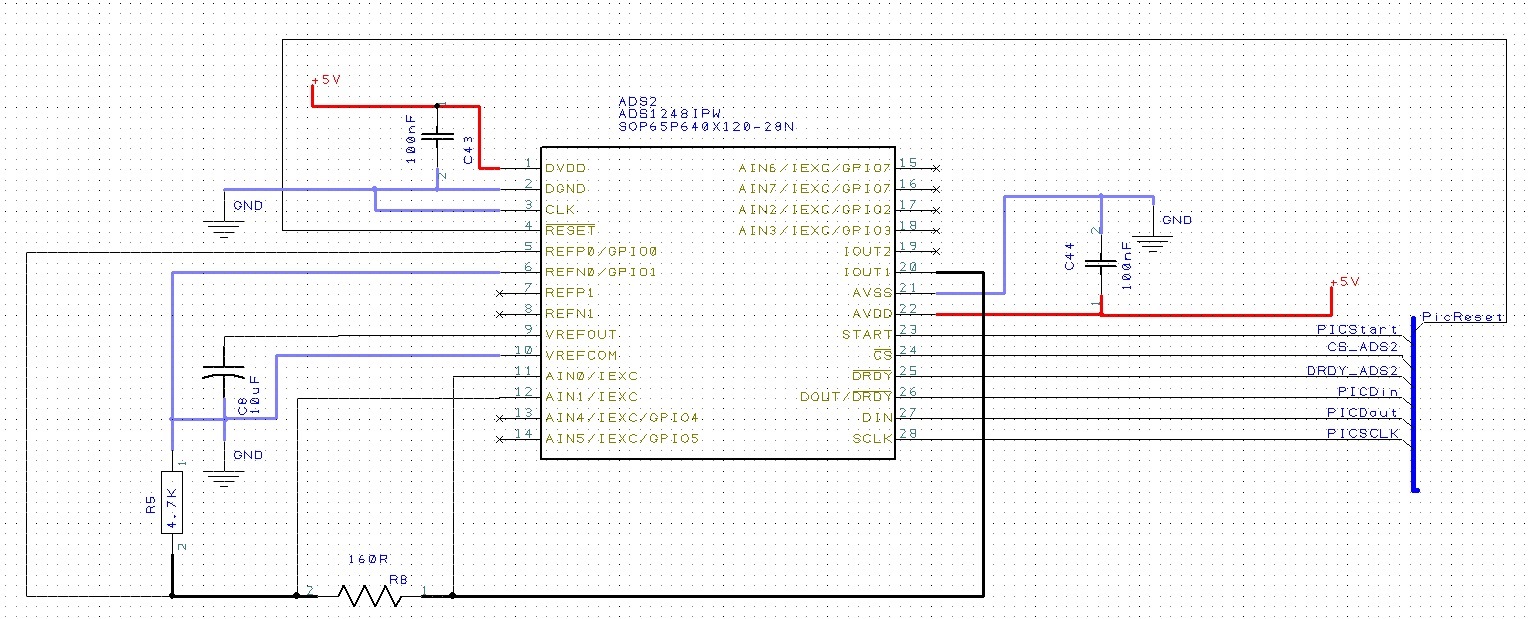

I have built a second circuit with a PIC18 controller on a printed circuit board and I am having the same issue.

Can someone please help?

Kind Regards,

Shiv