Dear Sir,

Question1,

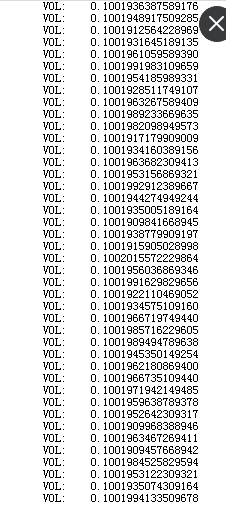

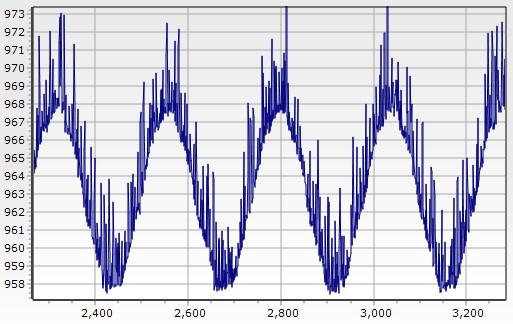

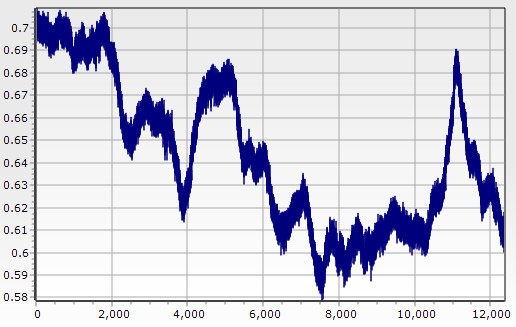

We just finish our PCB to test the ADS1262 performance. But the result is unsatisfactory. The Noise is about (200nV-300nV).

The signal is made by a very stable current source and very low TRC standard resistance. (We use the 7 1/2 multimeter can measure mach less noise than obtain by 1262).

Below is our parameter (reference LT1019A-3.3V; gain-8; chop on; filter sinc4; 2.5sps rates)

WritRegis(REFMUX,REFAIN0_G);

WritRegis(MODE0,CHOP_ON);

WritRegis(MODE1,FILTER_SINC4);///*Sinc4 mode

WritRegis(MODE2, GAIN_8| DR_2_5_SPS);//2.5sps

WritRegis(INPMUX,MUXP_AIN2 | MUXN_AIN3); //

Can you give us some advice for this issue?

Question2,

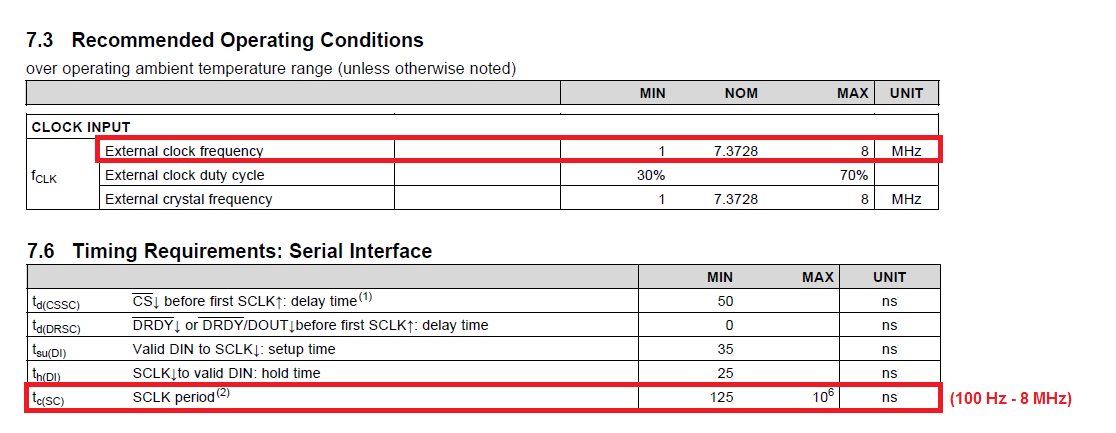

For ads1262 there are two stage filter first sinc5 and second stage variable-order filter.so the question is how to run the first stage filter, I don’t think is the reason of the importance noise.

thank you for your anwer.

Xavier-Pan