Other Parts Discussed in Thread: ADS1262, ADS124S08

Hi,

I am using ADS1248 with PT100 sensors on ports X1-X4 (3-wire RTD measurement). My communication between µC and ADS is ok, cause I read back the register values and all were ok.

I used high precision resistors on the input of the system to test the accuracy. My resistor is 164Ω ±o.1%

I write to registers:

0x01, //Data Byte of MUX0 - burn-out current source off, selected AIN0 and AIN1

0x00, //Data Byte of VBIAS - Bias voltage is not enabled

0x20, //Data Byte of MUX1 - internal oscillator used, internal reference is always on, REF0 selected, normal operation

0x22, //Data Byte of SYS0 - gain of PGA = 4, Data Rate = 20 SPS

0x00, //Data Byte of OFC0 - write 0

0x00, //Data Byte of OFC1 - write 0

0x00, //Data Byte of OFC2 - write 0

0x06, //Data Byte of IDAC0 - DOUT/DRDY pin only used as Data Out, current source = 1000µA

0x01, //Data Byte of IDAC1 - AIN0 and AIN2 are outputs of current sources

0xff, //Data Byte of GPIOCFG - GPIOs applied to AIN

0x00, //Data Byte of GPIOCDIR - write 0

0x00, //Data Byte of GPIODAT - write 0

My equation to calculate the resistance of RTD

R_RTD = (R_ref * final_output_code) / 2^23 // R_ref = 820 Ohm

The problem is that I calculate a resistance of 1639.99912 Ohm . I think the resistance is shifted about one decimal place. Right value would be 163.9... Ohm.

Now my question is, is my calculation wrong or something else ?

Thanks in advance

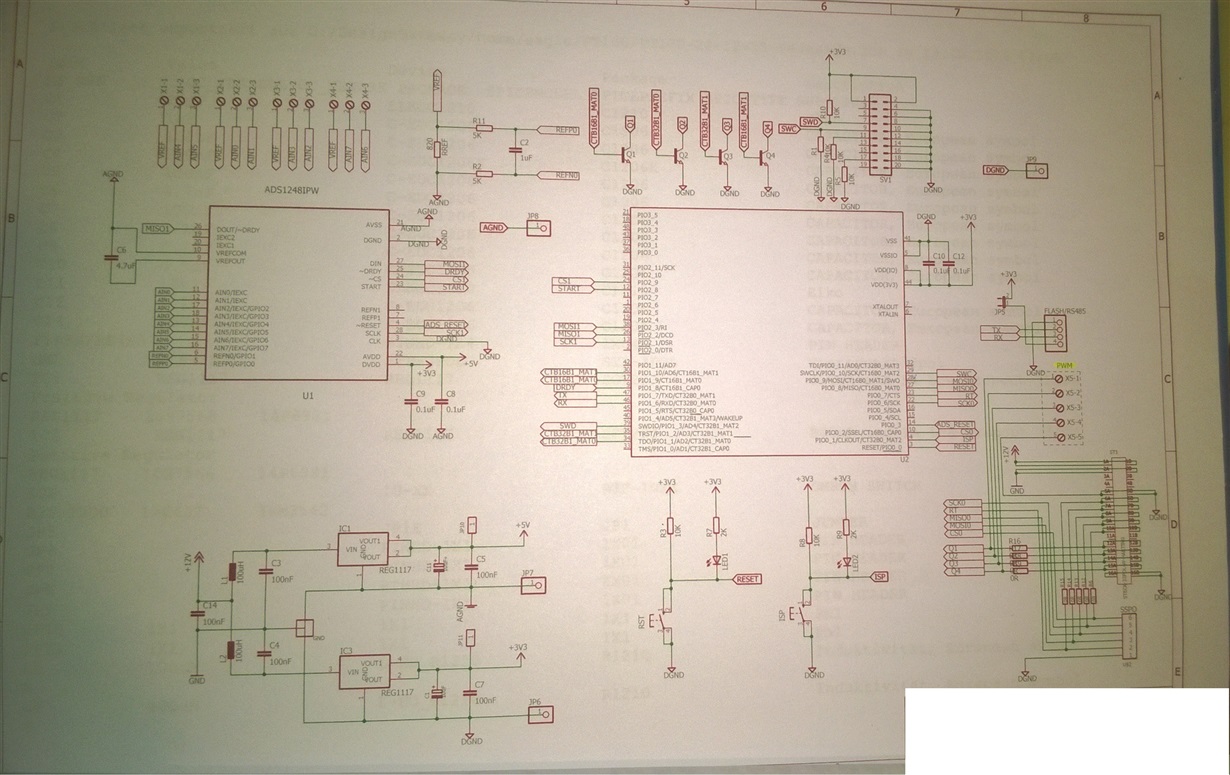

Here my layout: