Dear All,

for a student competition we need to use fast and high-resolution ADCs to sample data with Arduinos. However, after reading through the ADS8689 datasheet several times and trying variuos commands, we were not able to get any reading from the device.

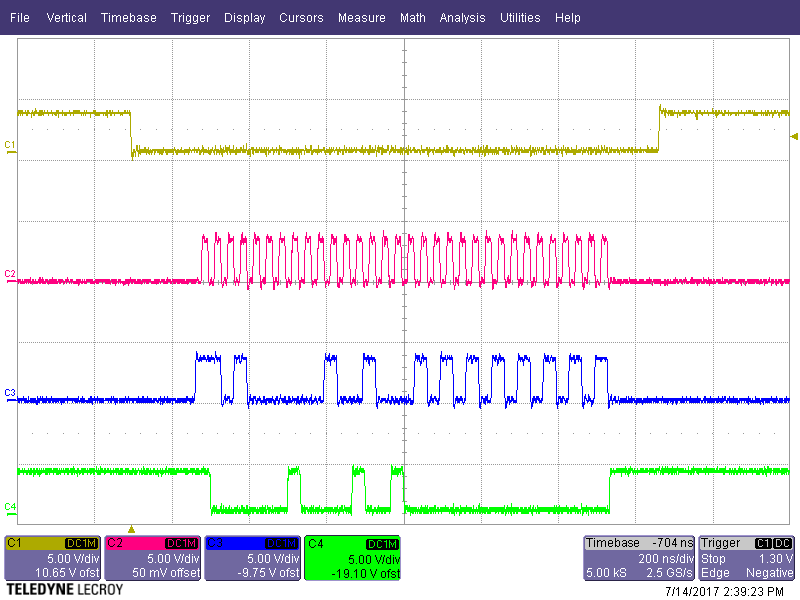

In order to check the data transmission I tried to read the ALARM_H_TH_REG Register to get FFh. So I send the following bytes after puling CS to low:

"01001000" (READ-command plus first bit of Address [48h], In the datasheet, table 5 it sais 01001_xx_<9-bit address>, thats why I added a zero the first byte... (correct ?))

"00100100" (Address for Alarm register [24h])

"00000000"

"00000000" (send zeros and simultaneously read incoming byte [00h])

Then I pull CS high again and wait for 500 milliseconds.

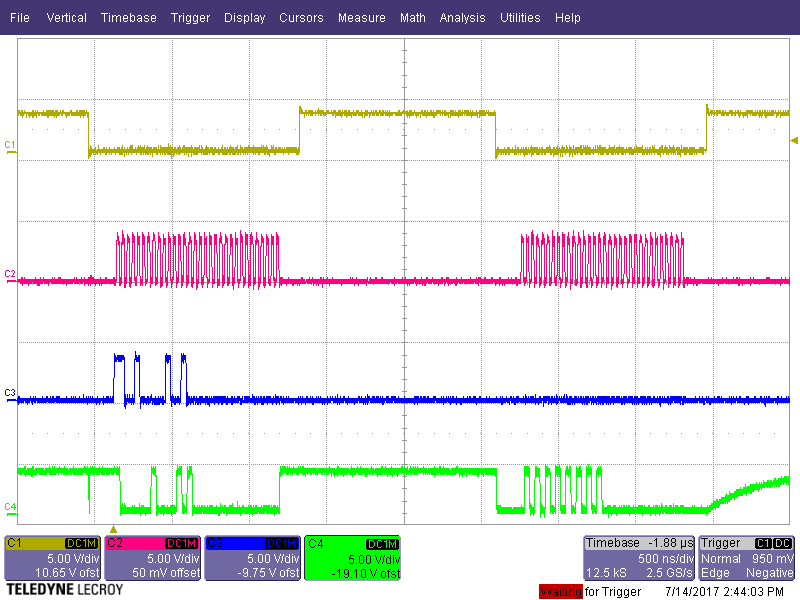

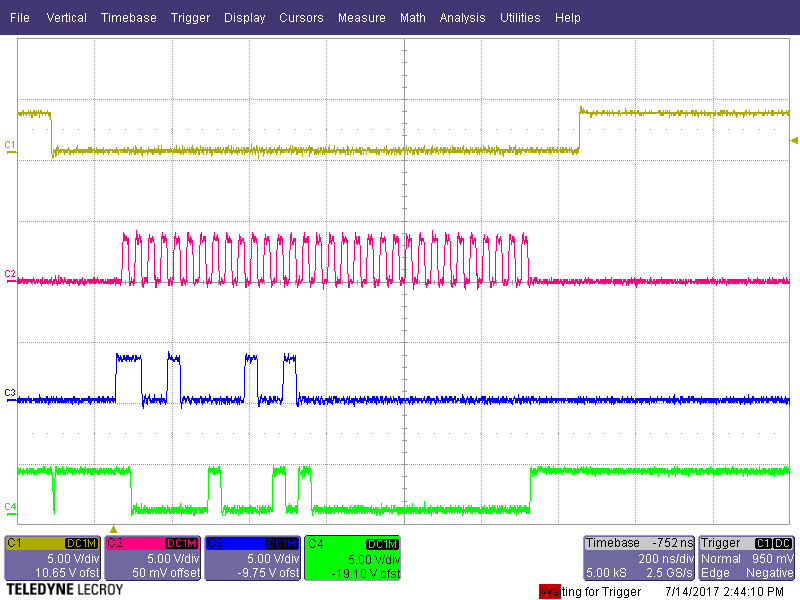

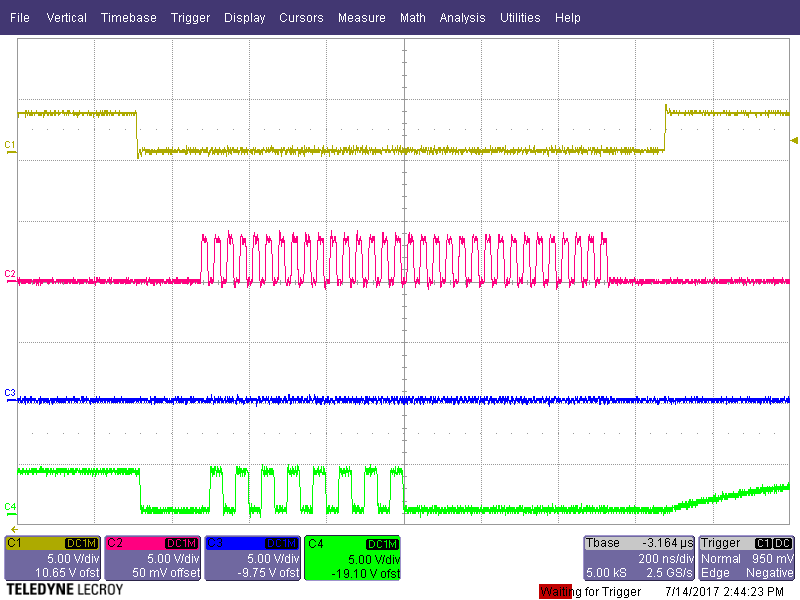

On the oscilloscope I see, that the MOSI bytes arrive, yet on the MISO there iss a byte during the first byte (READ) but zeros uring the next three bytes. So my reading is 00h.

Also, the MISO line doesnt go up after CS goes high. Is that usual? Are my commands incomplete?

Further Information:

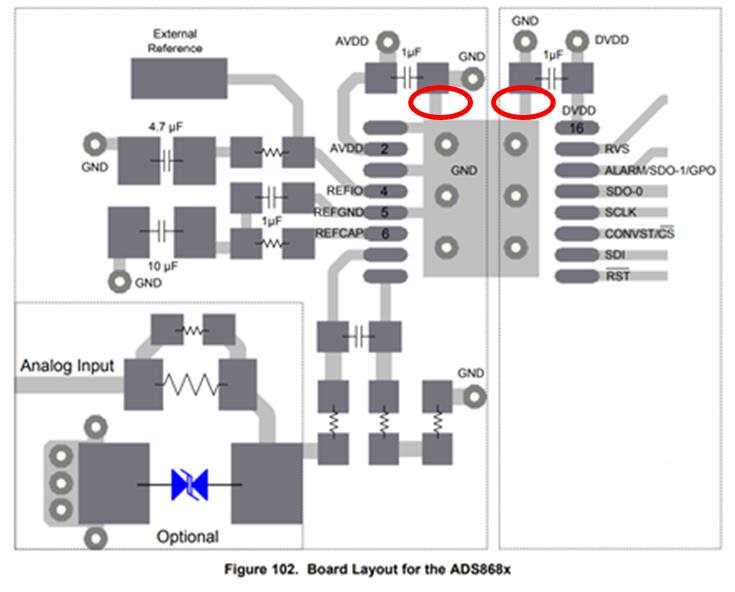

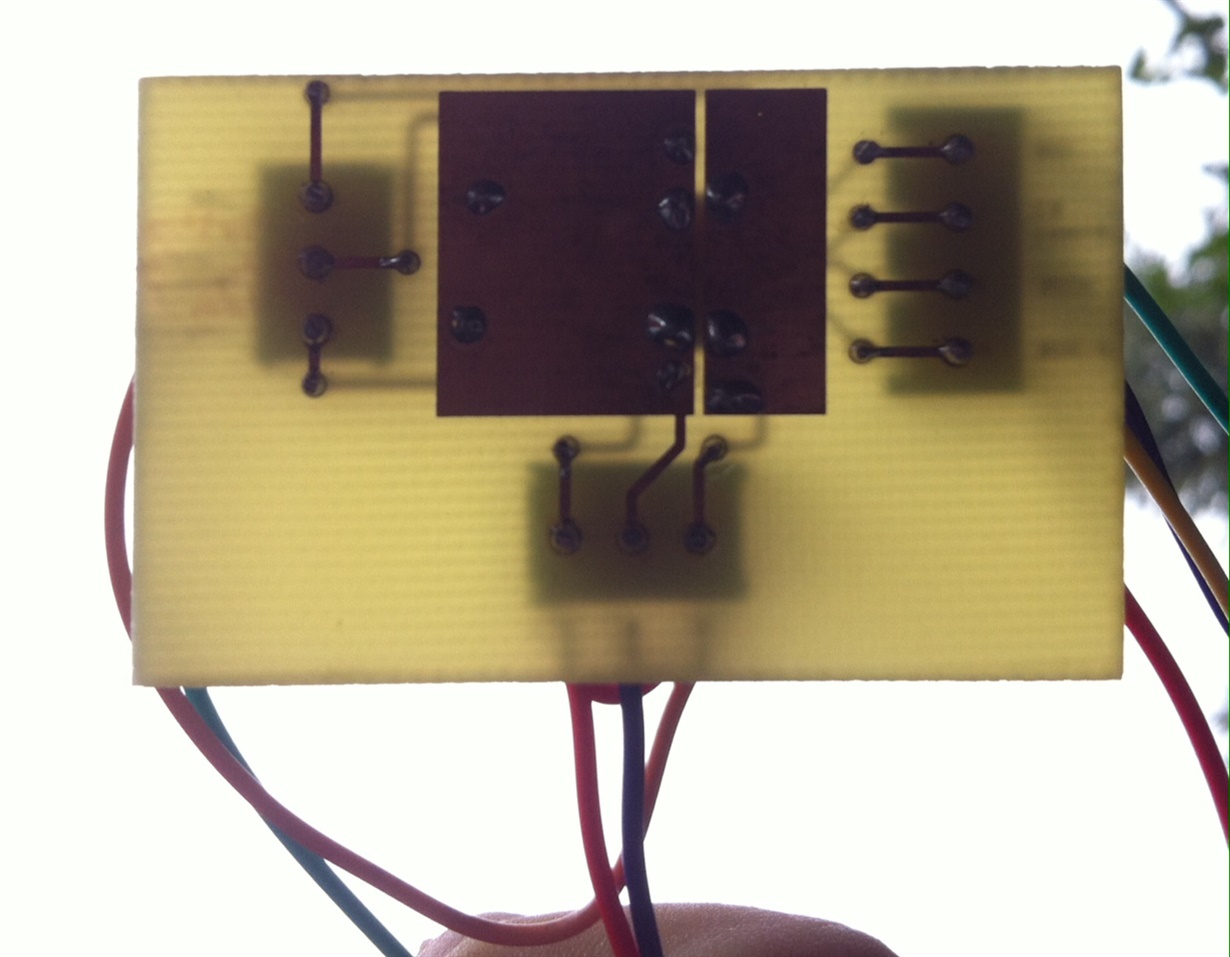

The ADC is mounted on a propper evaluation board, layout as in the datasheet.

I have exchanged ADCs and Arduinos, so failure of device is probably not the problem.

The SPI clock is set to 8 MHz, I also tried 2 MHz.

The Reset pin is constantly high.

Can anyone help or maybe has a sample code (any language)?

If you need more Information, just tell me :)