Other Parts Discussed in Thread: LDC1612,

Hi,

how can I increase the amount of change of LD1312.

only 20 units change when the metal touches to the antenna.

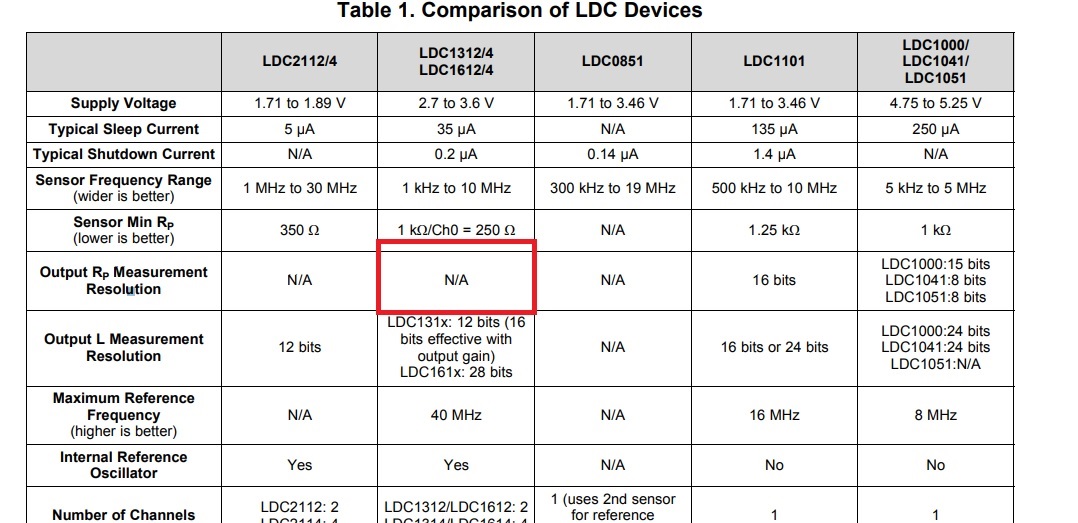

The following picture is an excerpt from the LDC Selection guide.( http://www.ti.com/lit/an/snoa954b/snoa954b.pdf )

why is the red box N/A ?