Other Parts Discussed in Thread: TINA-TI, , OPA333, OPA376, OPA191, OPA192

Tool/software: TINA-TI or Spice Models

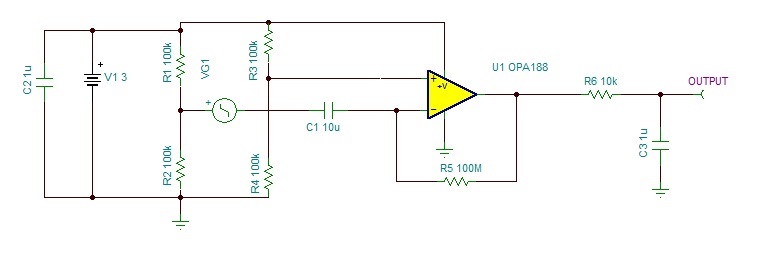

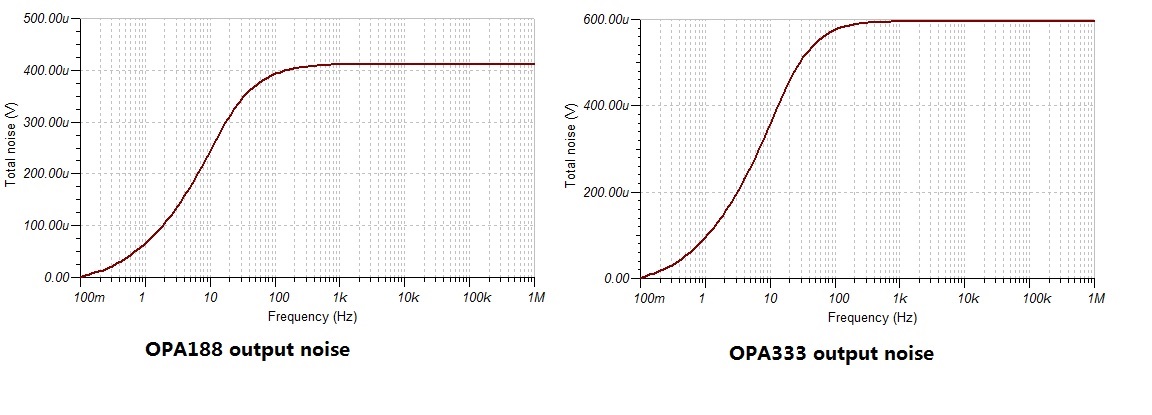

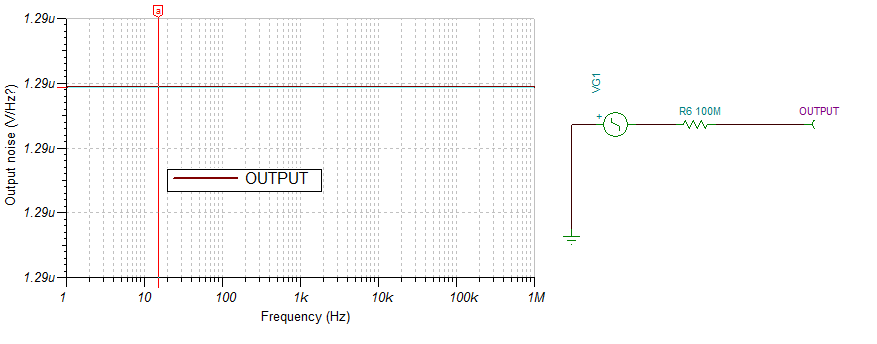

The output noise is very close when putting OPA333 and OPA188 in the following same circuit, why? known that the RTI noise is 8nV/rtHz VS 55nV/rtHz in the spec.

BRs, JH