Tool/software: Webench

Hi all,

I have an active design with the UCC28911 that uses design equations from the datasheet and leverages the WEBENCH model. I was informed on January 12th that there were issues with the equations and they've been corrected. Can I please get a list of the addendum / errata so I can verify my development equations? Was the datasheet changed?

"

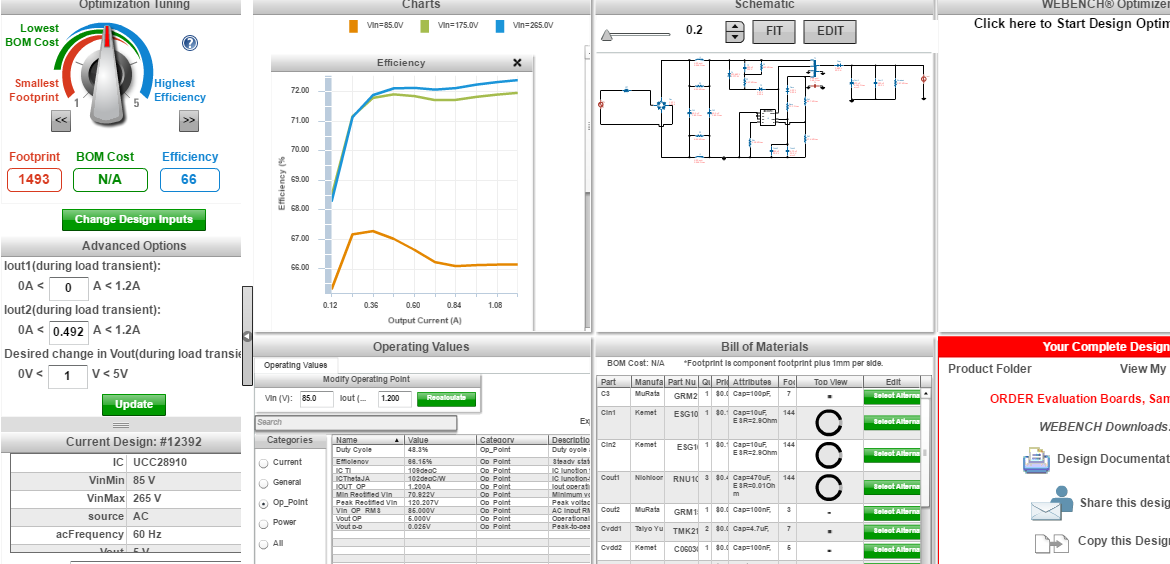

Updates made to the WEBENCH Design:

a. The Transformer Inductance calculation has been updated based on the desired set target switching frequency and the tool now supports improved core/bobbin selection with enhanced algorithm to give better transformer construction details(turns, AWGs, layers, strands, etc)

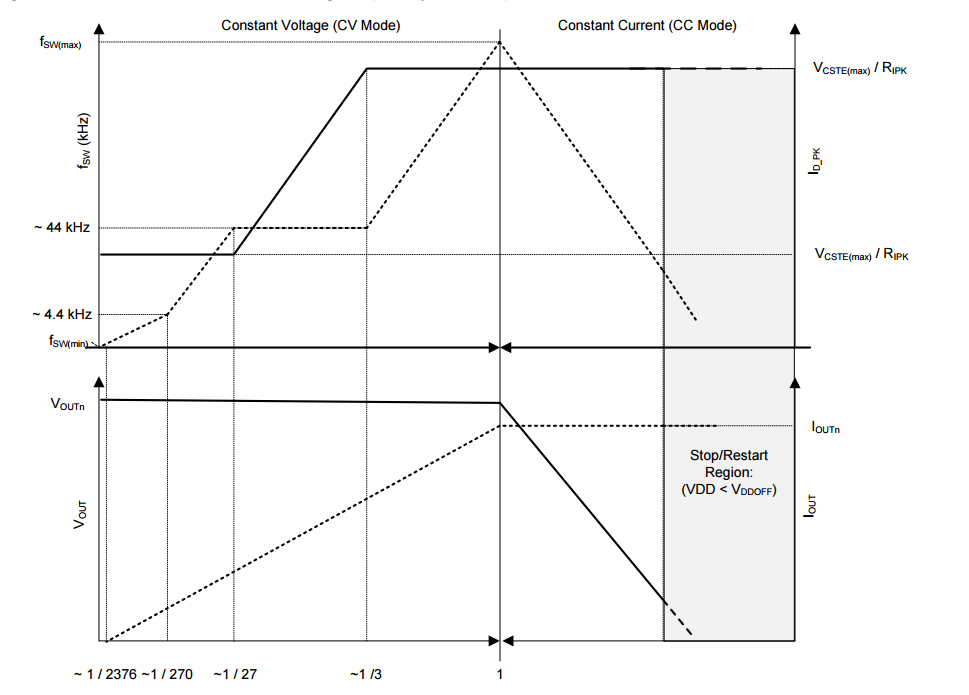

b. Rcs has been renamed to Ripk in the schematic and is re-calculated to set the value of Io(output current) in Constant Current mode with Dmagcc (secondary side conduction duty cycle) of 0.413

c. The preload resistor selection Rpreload has been made more accurate with the preload power sized so that it is higher than the Aux power

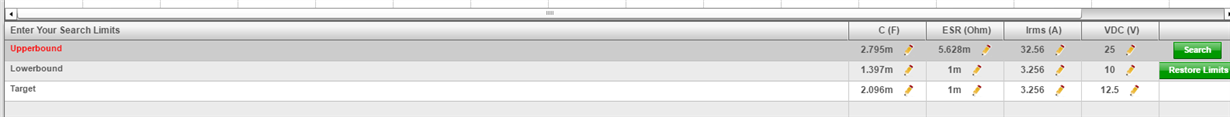

d. Advanced options for entering load transient is supported in the tool to help select appropriate Cout to fit in your application

e. The output preload resistor determines the converter minimum operating frequency. With the updated Rpreload value as mentioned in point c), Cout1 value will get automatically updated as well because the output capacitance is typically determined by transient response requirement from no load

f. Cvdd1 needs to supply device operating current until output reaches target minimum operating voltage in constant-current regulation. The time taken to do that depends on Cout. With an update in Cout( look at point e.), change in Cvdd1 value will also get reflected

g. With the update in Transformer Parameters(turns ratio, etc), we also encourage you to use the new values of snubber circuit comprising Dz, R3, C3, R4 , D1 along with the VS(voltage sense) pin resistors Rs1 and Rs2

"

Regards,

Aaron