Hi,

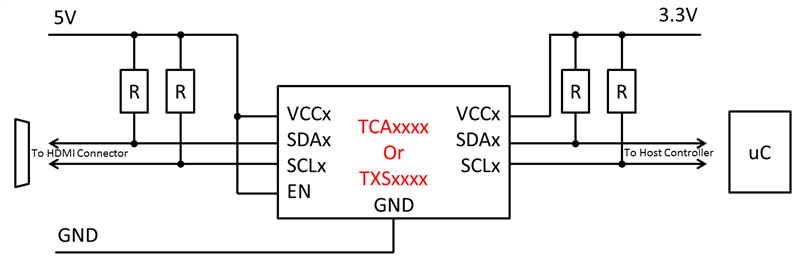

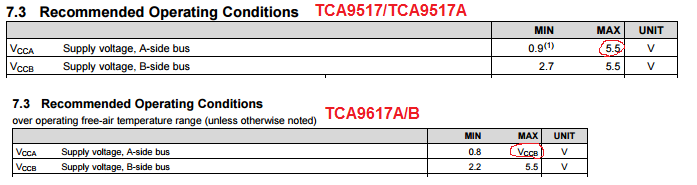

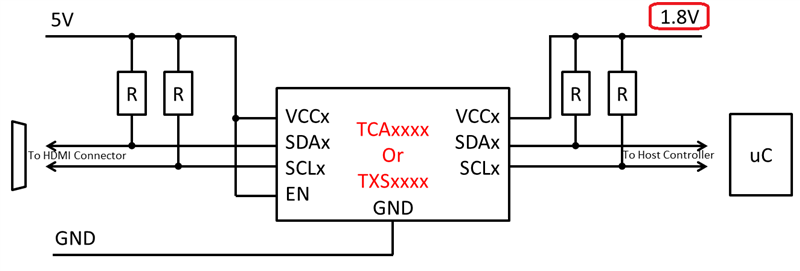

We are considering to use TXS0102 for 1.8V <--> 5.0V(the connector side) level shifting on the HDMI DDC(VCCA=1.8V, VCCB=5.0V).

So, is TXS0102 able to be applied to the HDMI DDC although TXS0102 supports the I2C bus ?

We are concerned the phenomenon such as the oscillations and especially whether passing the HDMI DDC compliance test.

Could you please suggest us your recommneded parts for the HDMI DDC based on your experience ?

Best regards,

Kato