Dear Sir/Madam

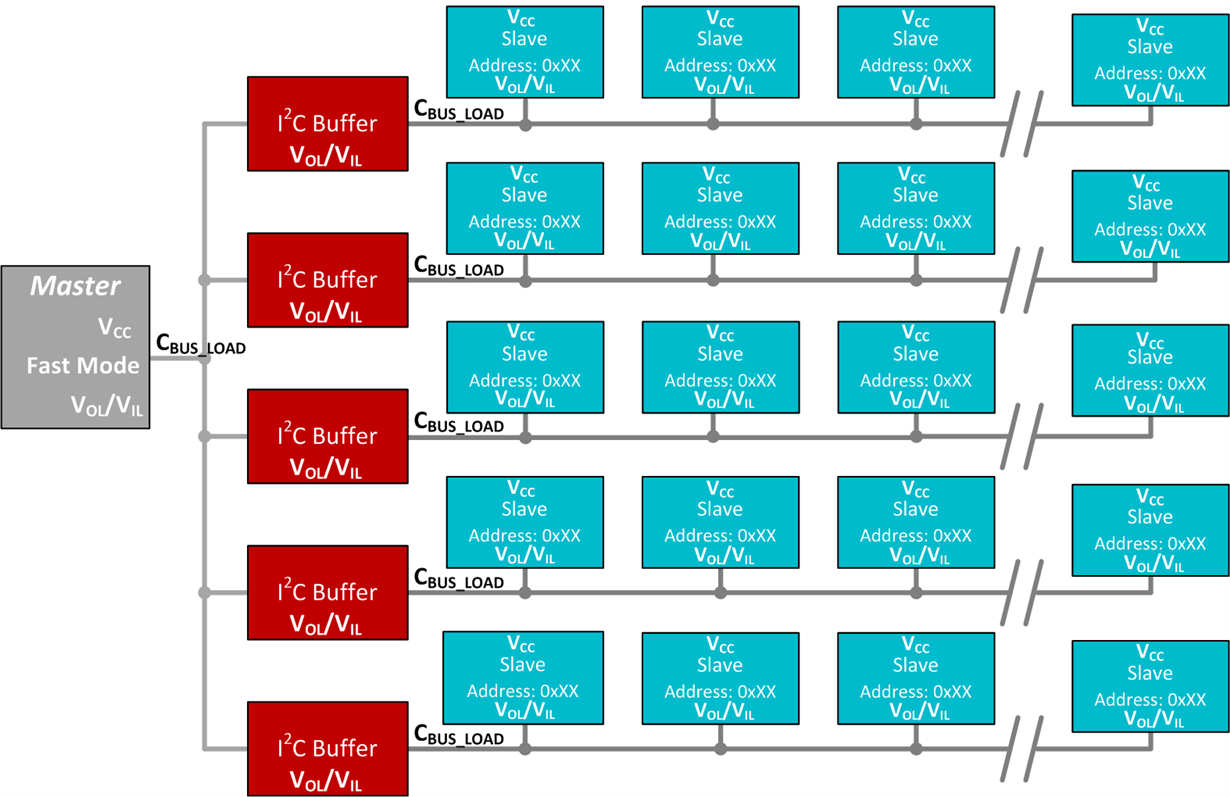

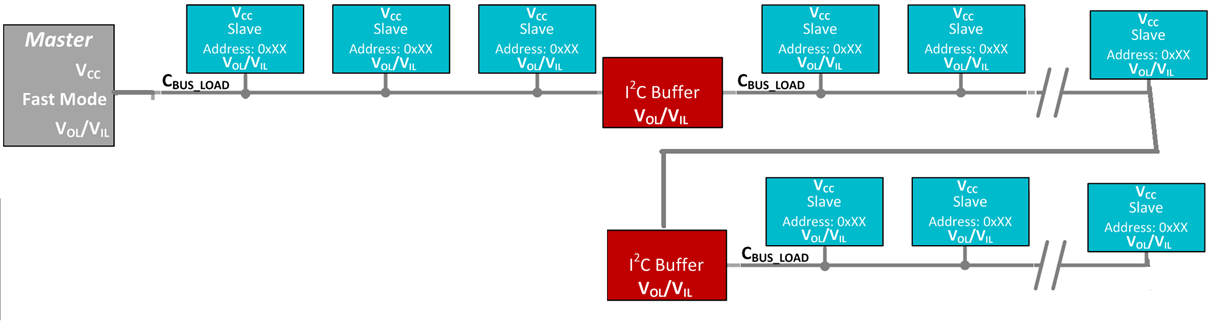

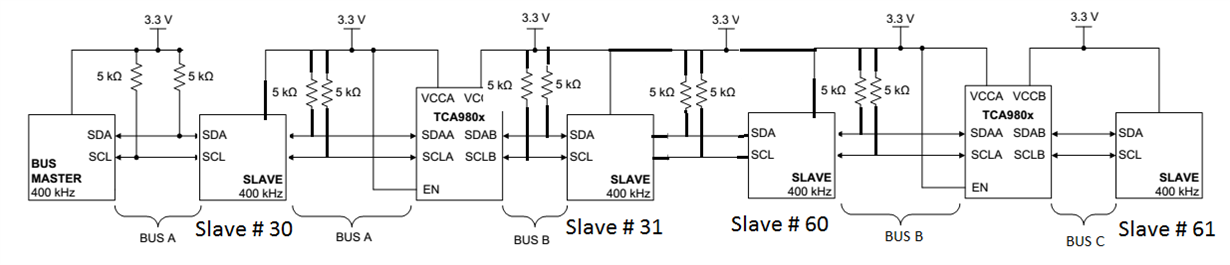

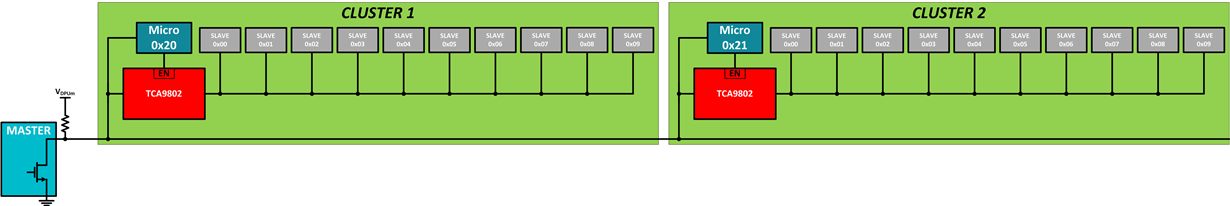

We have designed one system where we are using 7bit I2C address and connecting 30 slave boards to the Master board on same I2C Bus. My master and Slave boards are connected with PCB or Rigid+Flex PCB.

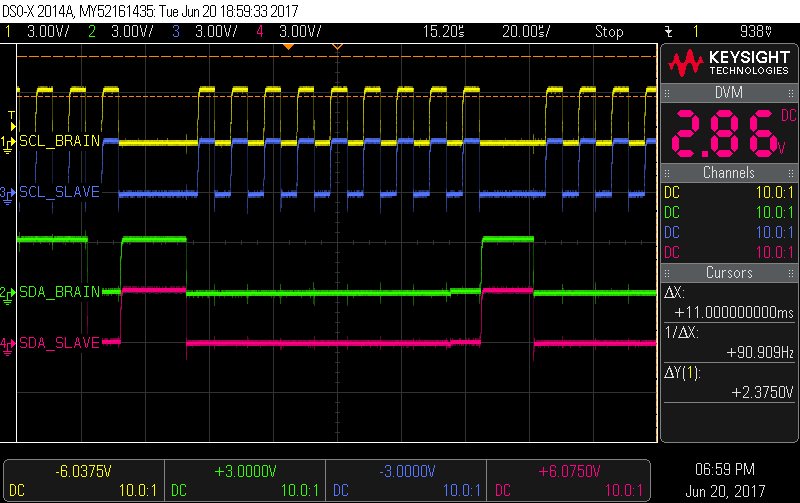

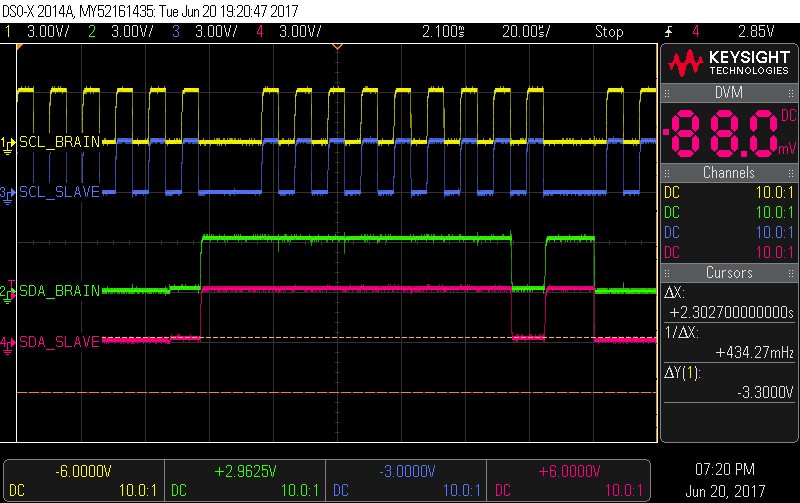

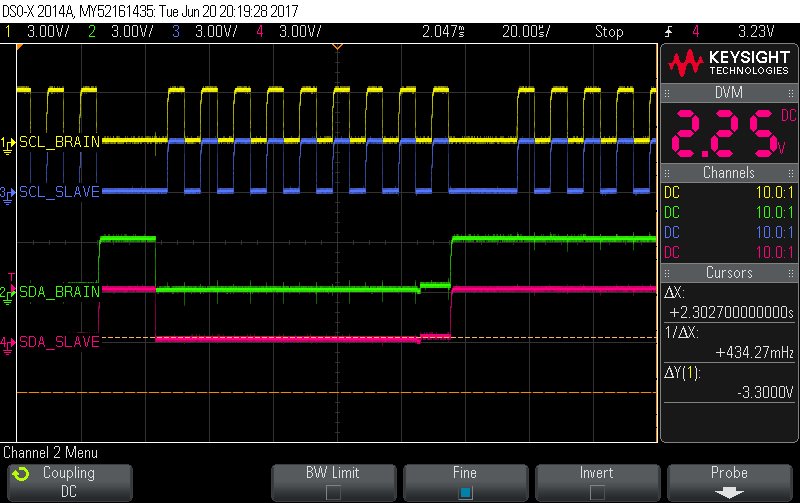

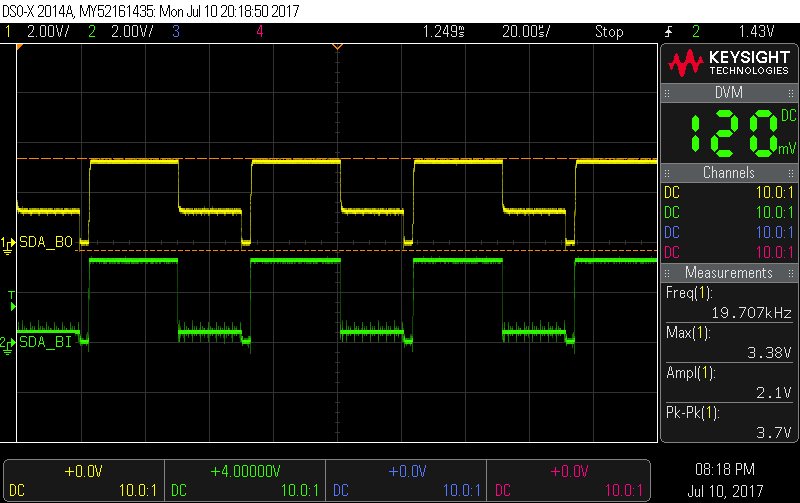

Attached is the I2C waveform which we captured after we connect 10, 20 & 30 Slave to the BRAIN/Master. Brain/master and each slave using 4.7k pull up resistor with 3.3V & each slave is generating its own 3.3V and GND is common in the whole system.

Now my question if we use 10bit address to connect more slave to the same I2C bus, will it be allow me to connect on the same bus without any problem, based on the attached waveform? Can you please guide how we can check and verify the same? The newer slave will be same as earlier 10/20/30 slaves and will have the pull up of 4.7k

In nut shell if we use 10bit I2C address and BRAIN is connected with 1020slaves(BRAIN and Slaves connected with PCB and connector, no cables used to connect them) what parameter we check and how so can be sure that i can physically do the same. Please help/guide so we can expand the system.

Thanks

Krunal Shah