Other Parts Discussed in Thread: ISO7842,

Dear all,

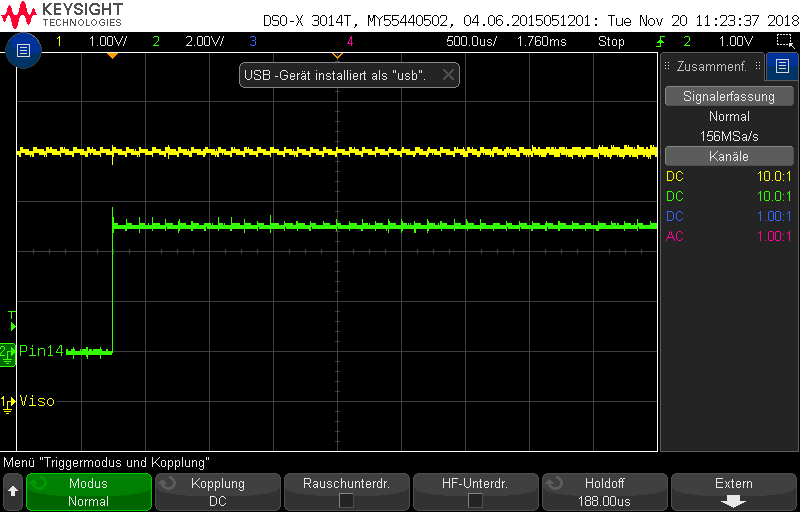

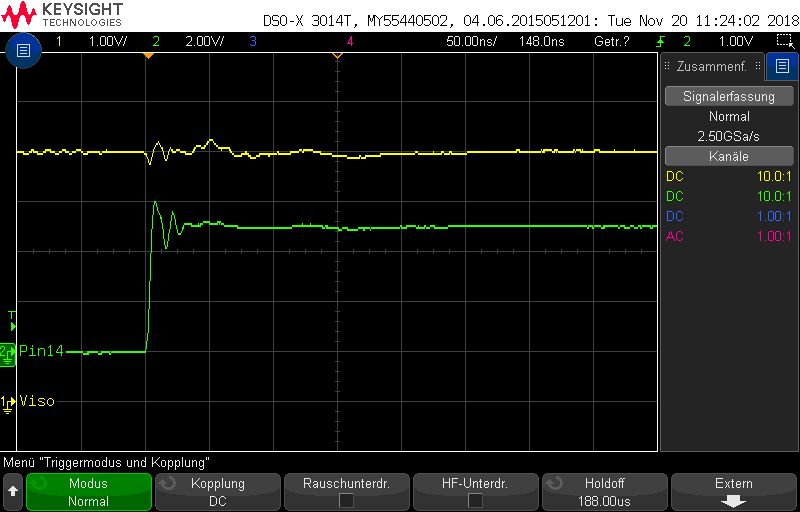

we are using the ISO7842 in one of our products to control an isolated switch as depicted in the picture below. "control signal" has logic high voltage level for a maximum of 1.5s and therefore, the switch closes (load: 1A) and then reopens again. On some of our PCBs we observe the following problem:

"control signal" is activated (high) for 1.5s, the switch closes and then reopens again. But after 1.5s, the ISOW7842 heats up caused by a short circuit of Viso/GNDiso (it is definitely the chip itself, after removing it from the PCB the short circuit on the PCB also disappears). In general, the ISOW7842 is not damaged the first time when "control signal" is activated, it needs some trials until the short circuit appears. Is there a mistake in our circuit (maybe the high impedance connection of primary and isolated ground) or a known issue with the isolated supply?

Kind regards.

Sebastian Reichhold