Hi,

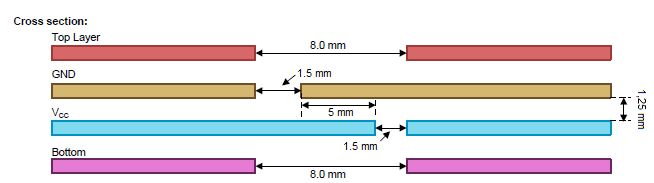

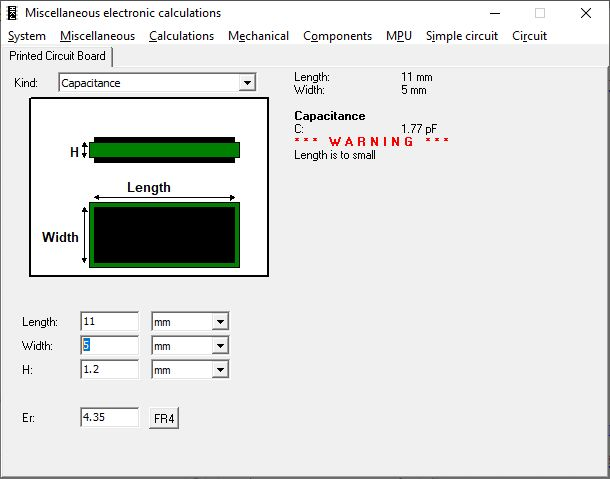

My customer is trying to follow SLLA368C chapter 4 for the interlayer cap implementation, but the max features that they can do are shown below:

They would like to know if you recommend implementing this interlayer cap, or to just add SMD caps on the top and bottom layers? Any guidance would be appreciated.

Regards,

Antonio