Specific Device PN: SN74AHC05PWR

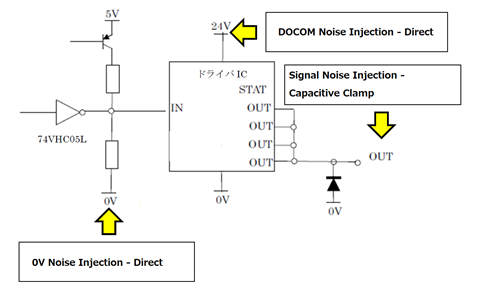

Customer was performing some over-stress noise tests, (see following) and the device ignited into flames at the following conditions:

Test 1: Noise applied to the signal line(OUT) of greater than +2.4kV or less than -4kV caused ignition and fire(capacitive clamp)

Test 2: Noise applied to the DOCOM(24V) line of greater than 1.6kV and under -1kV caused ignition and fire (direct)

Test 3: Noise applied to GND (0V reference potential for device) of >+1.8kV or <-2.0kV caused ignition and fire (direct)

For Test 3, the kV-rating where ignition and fire happened varied with the location on where the 0V line noise was injected.

Because these were over-stress conditions, they know nothing is wrong with the TI device functionality. But they would very much like to avoid failures with ignition and fire. Are there any design considerations or steps than can be taken to mitigate fire during device failure?

Also, they very much hope we can provide them the mechanism on how such a failure could occur. At such high noise voltage (not sure how long the pulses were...), is it the bonding wires melting and igniting the package that cause such a failure? What is the flame-retarded rating of the packaging material...?

Regards,

Darren