Hello,

we have a problem with the rsonline feature. We are using a 28027F with DRV8301.

We got two different programs, one which has the RsOnline feature working and one which don't. Let me explain:

Application 1 (working RsOnline):

After application start the system is enabled with RsOfflineRecalc and OffsetRecalc enabled and Speed set to zero. After this "calibration" which is always done we are actively holding the motor at zero speed until an external speed reference is set. This allows for fast startups because the rotors are already aligned.

While accelerating and at steady speed the RsOnline feature is activated and runs as expected without problems. (In other cases it is deactivated, see code below)

Application 2 (RsOnline problem):

This application works the same as Application 1 with THE ONLY difference that we are not holding at zero speed because the motor should be moving freely without an external speed reference. This means that if the speed is zero (also after calibration) we are deactivating the control and reactivate it when a speedreference is set.

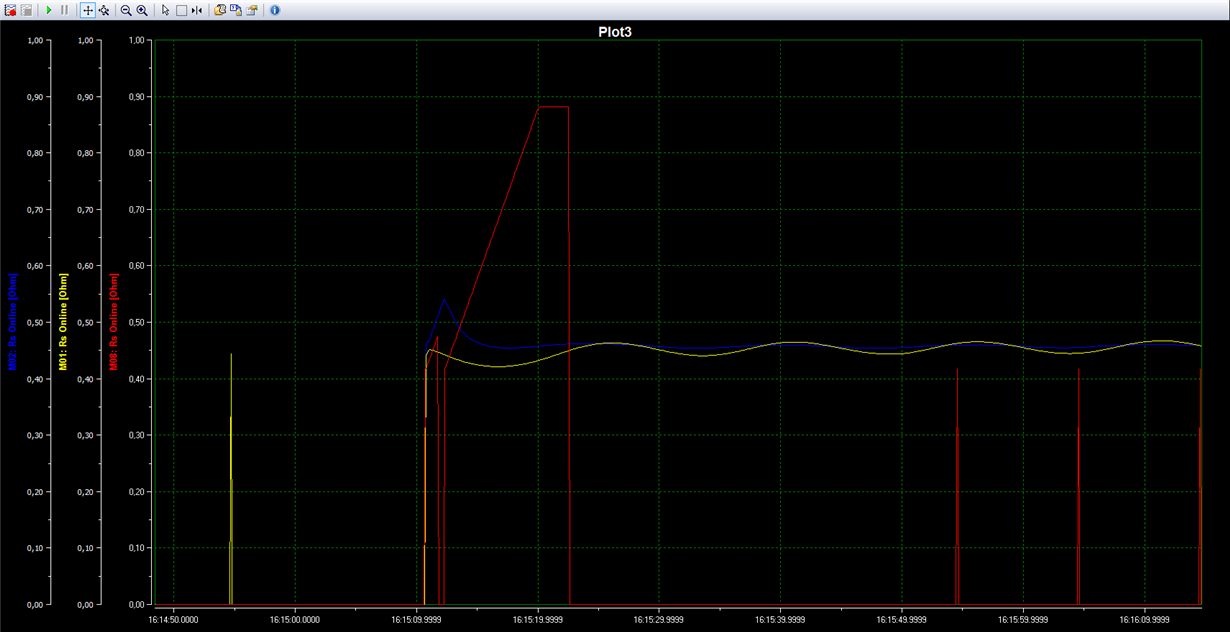

In this scenario as soon as we are activating RsOnline calculation the RsOnline value starts oscillating between 0 and 0.8 (roughly) and also the motor speed is not as accurate as it is in application 1. If we disable RsOnline calculation at least the speed accuracy improves.

What could cause this behaviour?

Here is our RsOnline implementation taken from the motorware manual pdf: