Hello Everyone,

I am currently seeking to buy some equipment for motor control experiment and I am interested in TI's "2MTR-DYNO InstaSPIN-FOC Evaluation Module" (www.ti.com/.../2MTR-DYNO

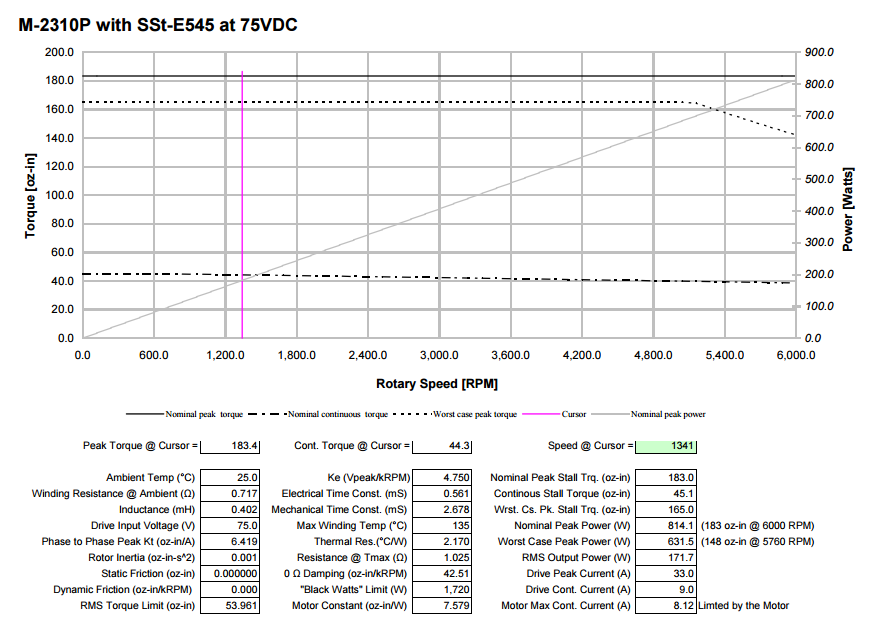

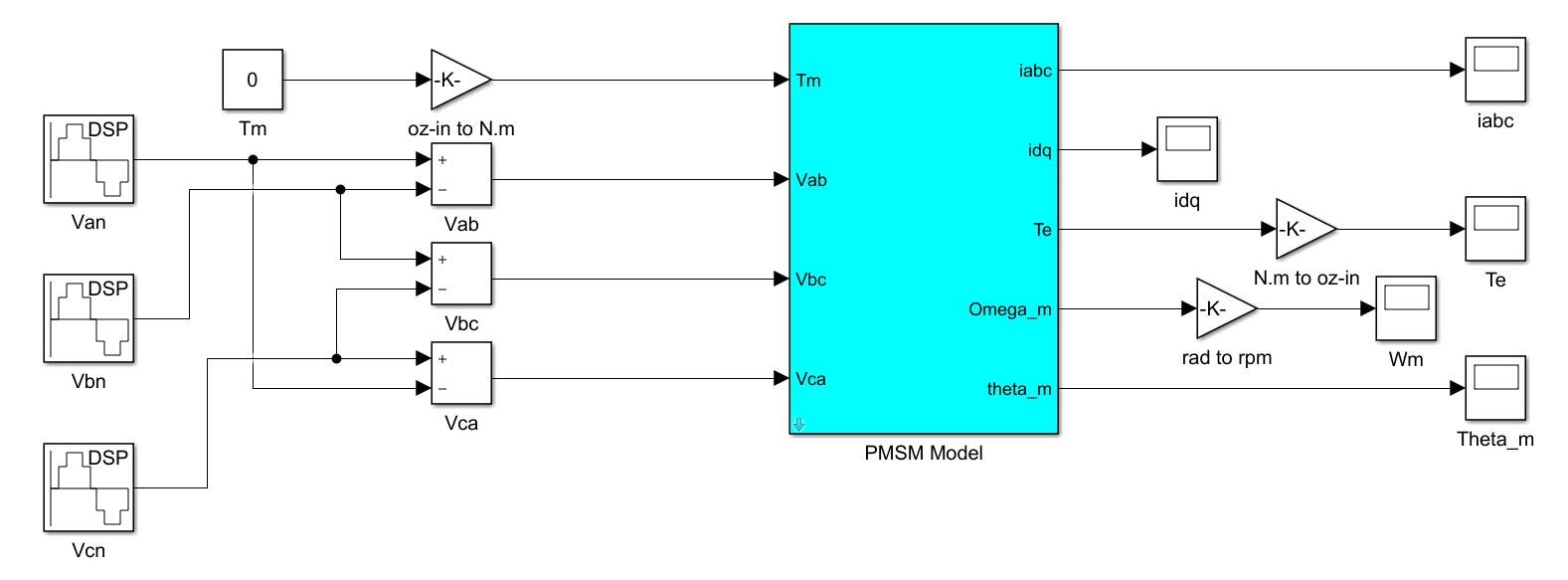

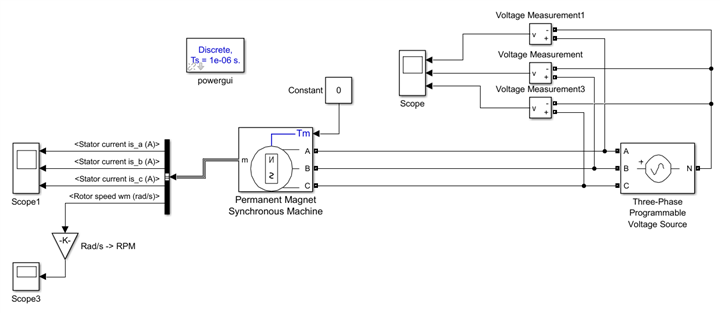

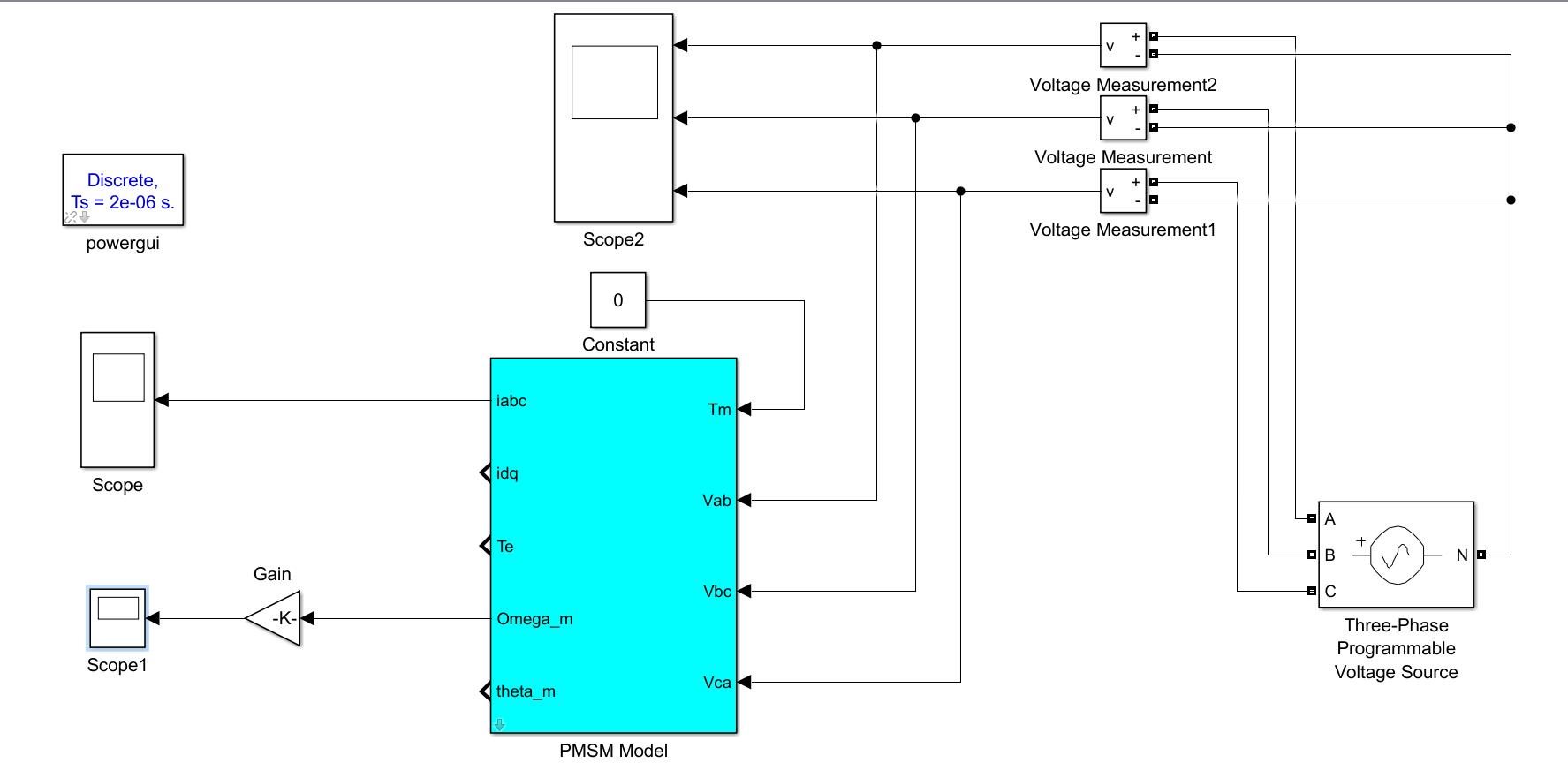

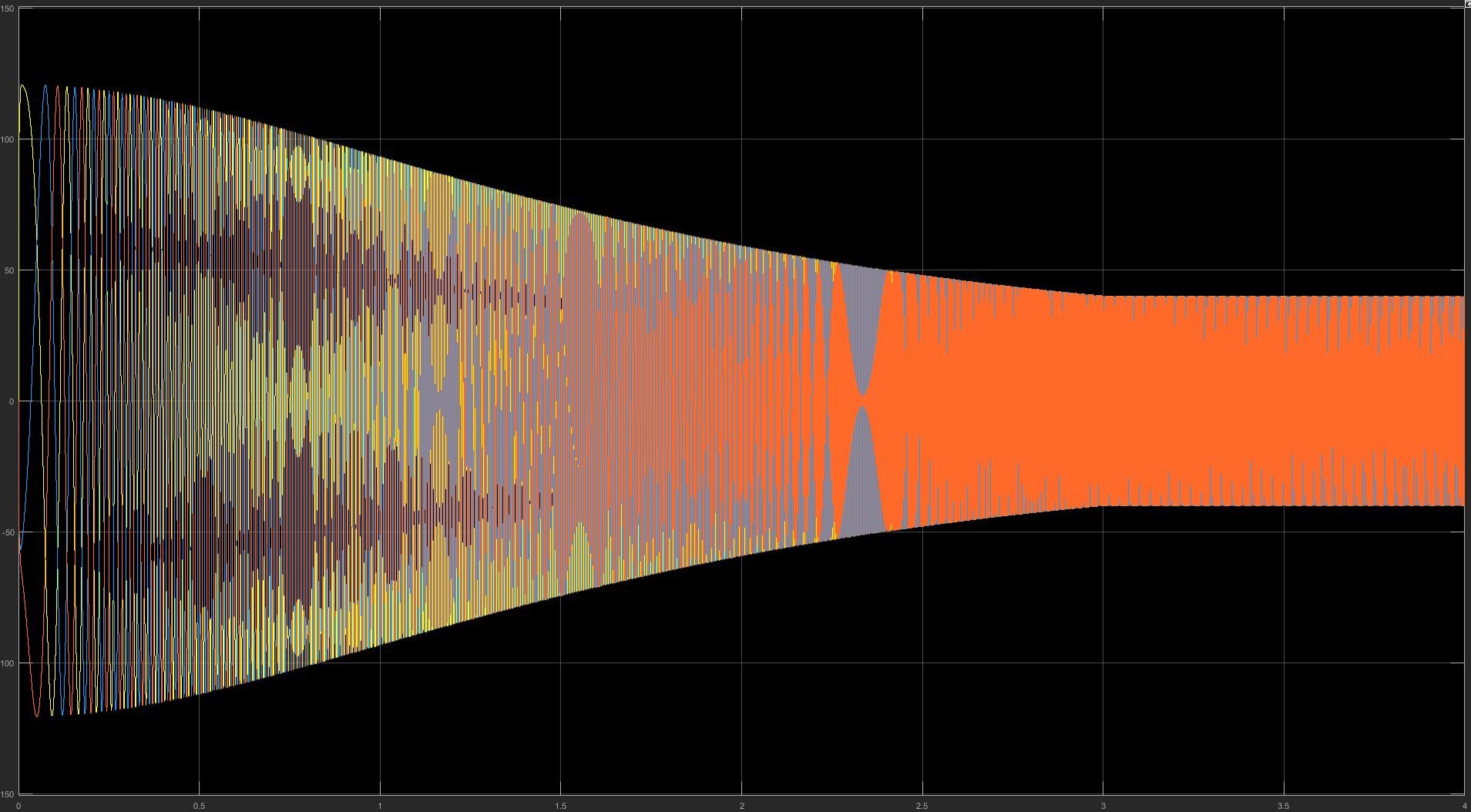

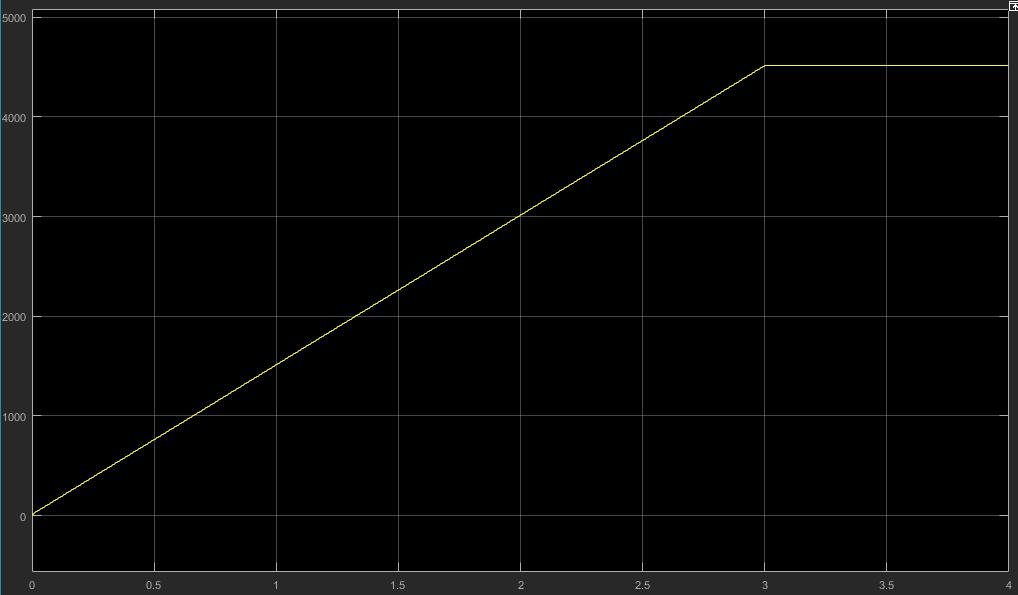

To guarantee that I made the right choice, I want to test the control performance of my designed controller on this motor first using Simulink. However, after looking both TI’s website and the datasheet provided by Teknic (according to TI’s website, the motor included in this evaluation module is Teknic’s M-2310P-LN-04K), I was unable to find the necessary specifications of this motor to start my simulation.

The datasheet of the M-2310P-LN-04K can be found at the following website:

https://www.teknic.com/files/product_info/N23_Industrial_Grade_Motors_v6.3.pdf

It provides me with the following information

Motor Poles: 8

Resistance, phase to phase 2.87 Ohm

Inductance, phase to phase 1.61 mH

Electrical Time Constant 0.56 ms

Back EMF Constant 9.28 Vpeak/kRPM

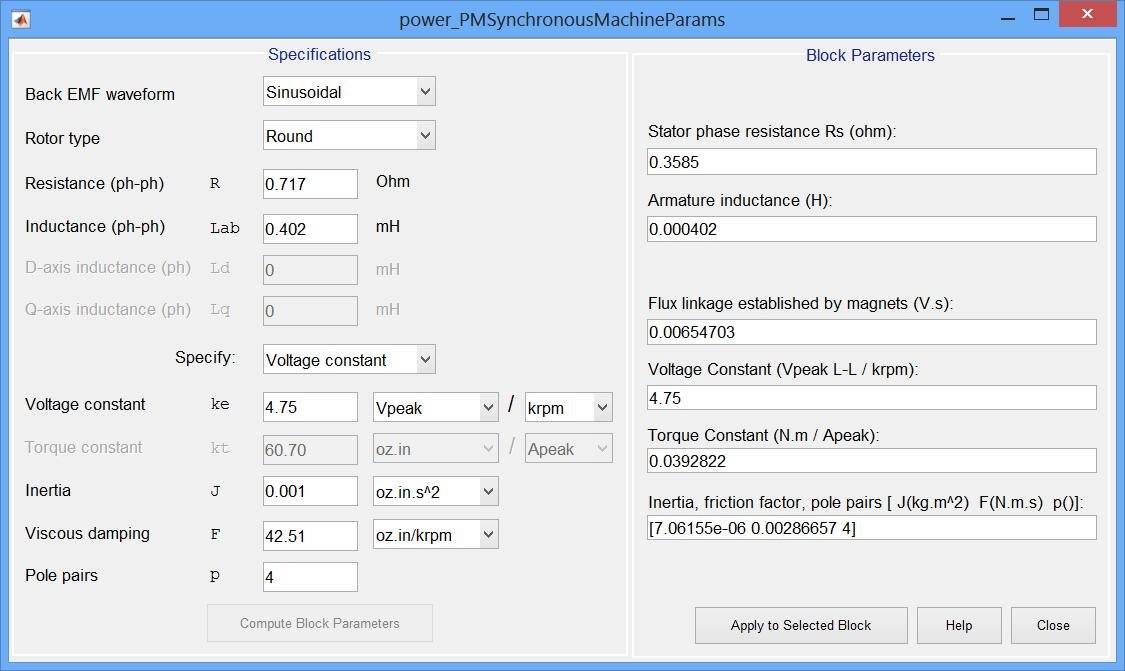

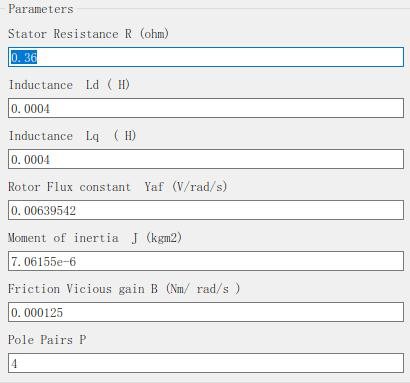

Based on these information, I am able to calculate the following motor specifications

Pole Pairs 4

Stator Phase Resistance 1.435 Ohm

Armature Inductance 0.00161 H

Flux Linkage established by magnets 0.018089 V.s

However, I am unable to acquire the following motor parameters which are necessary for my simulation

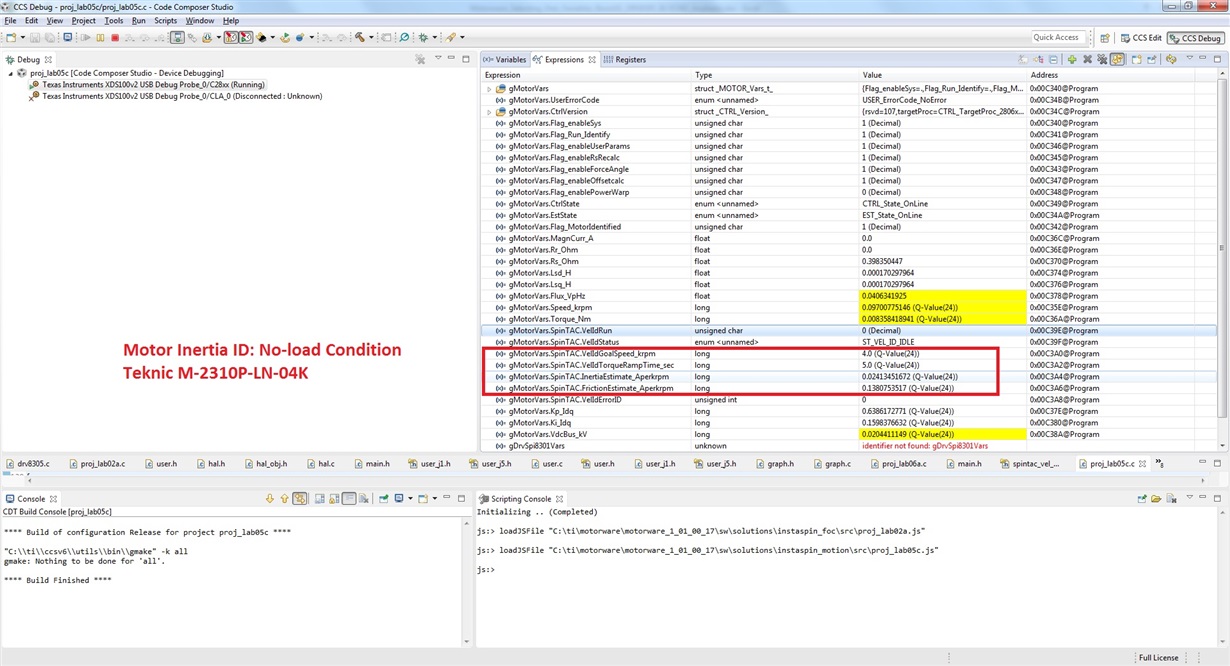

Rotor Inertia kg.m2

Viscous Damping N.m.s

Rated Current A

Rated Voltage V

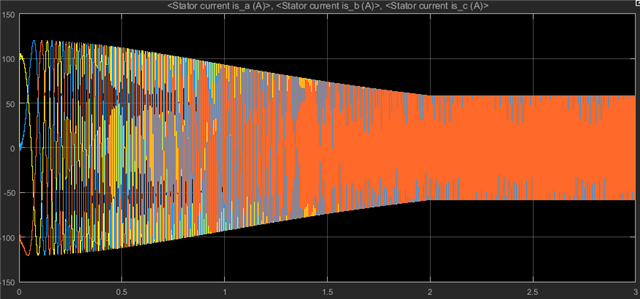

I know that the best way is to buy this product and measure it by myself. But the controller I designed is highly sensitive to sampling time. The minimum sampling time supported by the ADCs on my dsp board is 1 ms. If later I found that I need a sampling time less than 1 ms to control this M-2310P-LN-04K motor, it would be a waster for me to buy this product. I have very limited budget for my experiment and I don’t want to waste it.

The experiment I need to finish is crucial for my Ph.D. thesis and is very important to me. If anyone here can help me figure out how to acquire the above motor specifications, I would really appreciate your help.