Other Parts Discussed in Thread: C2000WARE, POWERSUITE

Tool/software: Code Composer Studio

Hello,

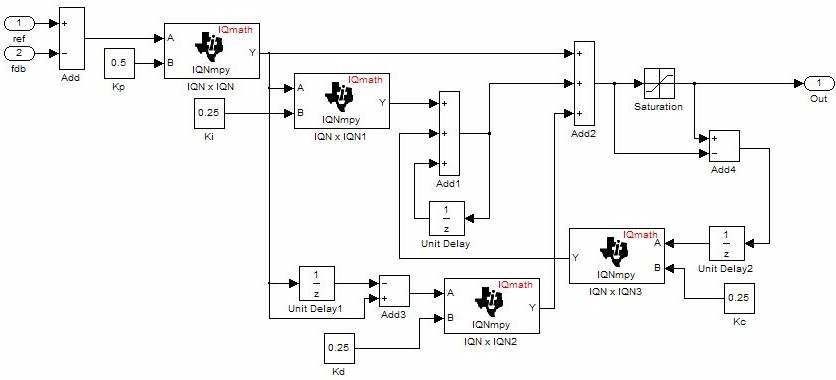

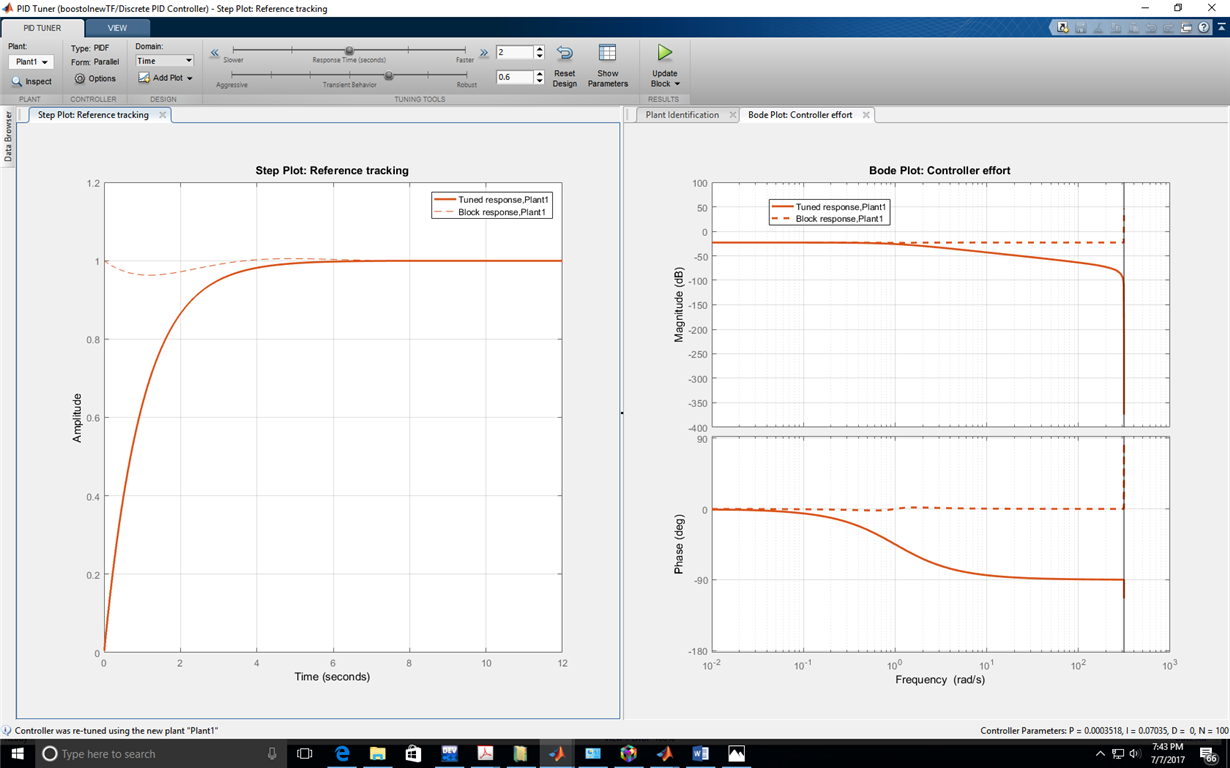

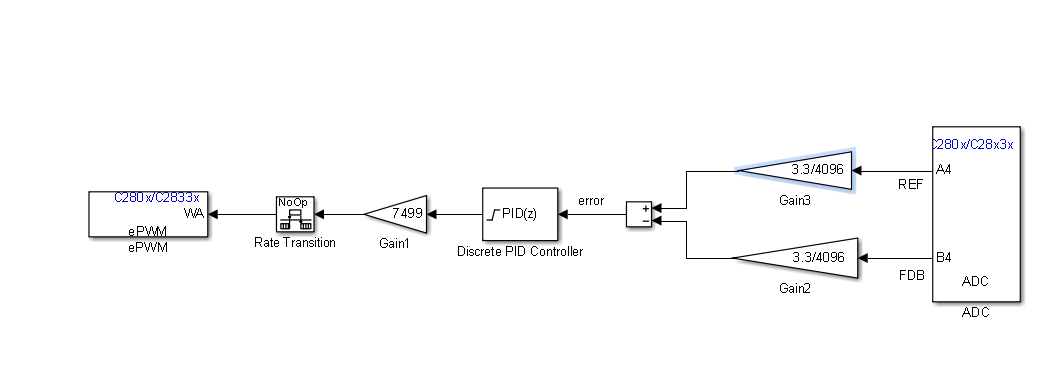

I am trying to use the DMC pid block in Simulink for closed loop control of an ordinary boost converter on a breadboard. It seems to be giving the right output but the performance of the PID is very worrisome. The output of PID that controls the gate driver of the mosfet is completely unstable, I mean the pulse it yields is unstable. In short, the PID forced to gate driver to operate at either 100% or 0%, as a result, the inductor current was huge. To confirm what I was seeing I simulated the boost converter on Simulink using the ordinary continuous PID controller and compared the results with the one in which I simulated with the DMC PID controller. I discovered that with the DMC inductor current was about x20 with respect to the current gotten when I used the ordinary continuous PID controller. I am convinced there is a major problem.

Additionally, I went through the PID portion of the embedded coder generated C code, the code made complete sense as it is based on ideal PID, I mean I couldn't find any error in the code. So what could be wrong? Or how can I get another tested/good PID controller. Plus, I have also tried the PID controller in the C2000 buck-boost converter example. It didn't work toooooooo. I already have a solid integrator constant, I just need a digital PID to carry it out.

I believe PID is something almost everyone here would know about and probably have used at some point; therefore, I would appreciate tips and assistance. Below is the PID I am talking about (default constants).

Thanks.

David.