Hi

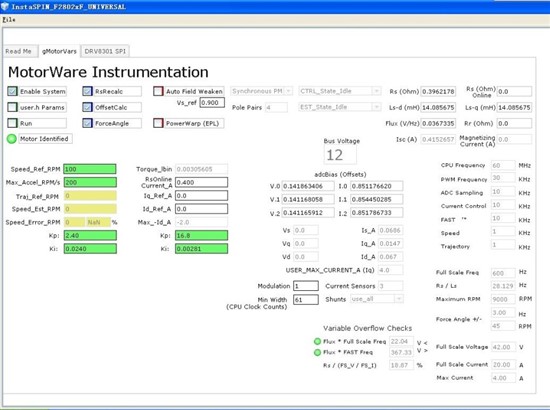

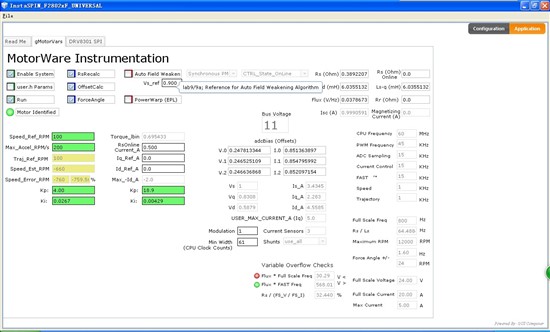

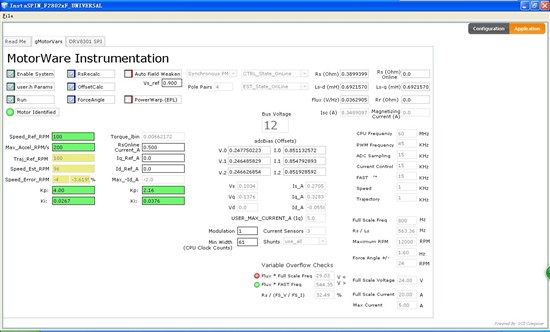

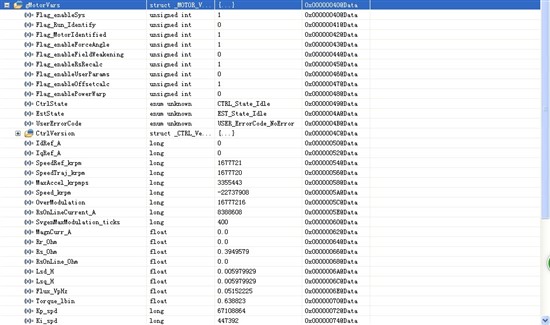

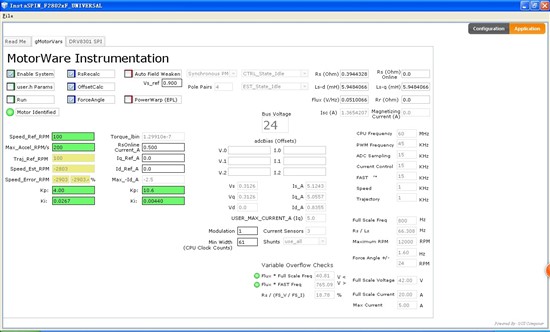

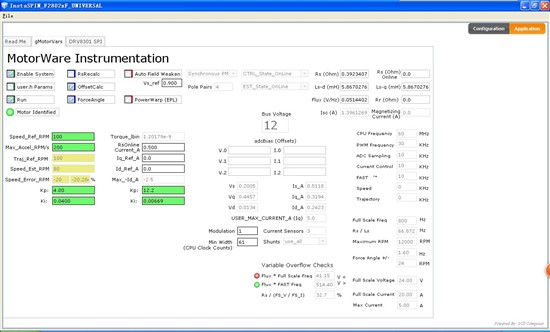

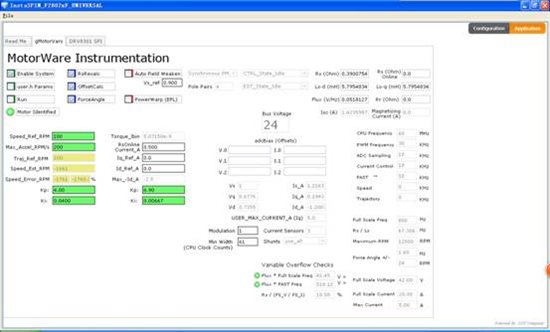

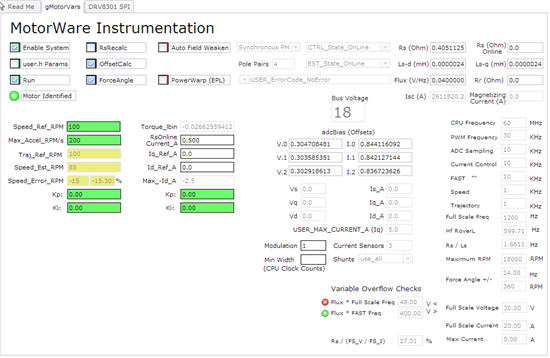

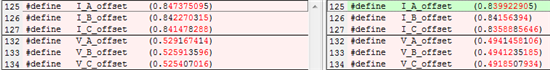

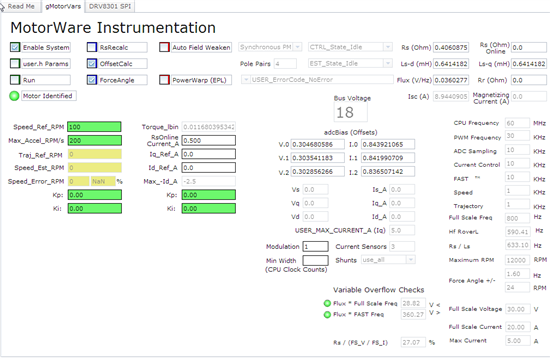

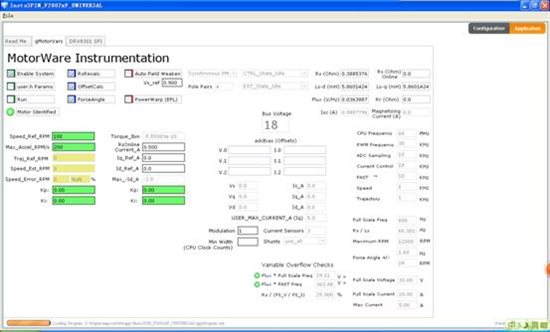

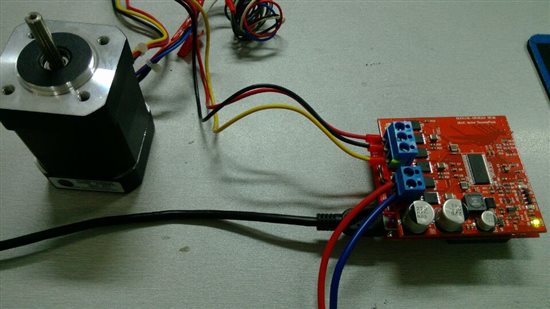

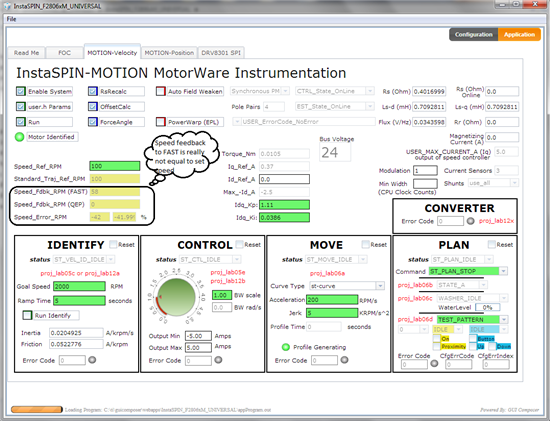

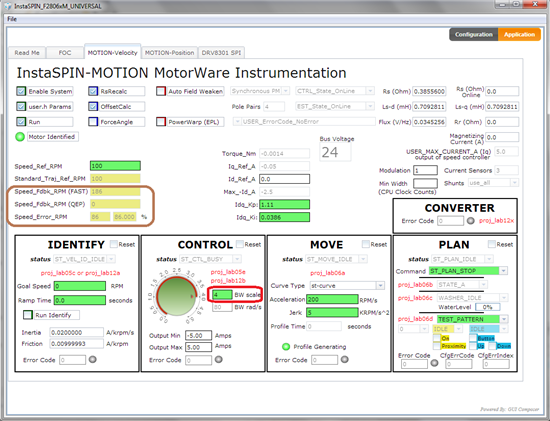

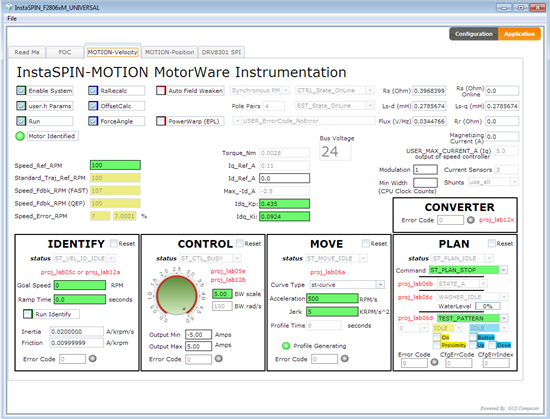

When I used the BOOSTXL-DRV8301 & LAUNCHXL-F28027F to identified the value of motor . My motor is DT4260-24-055-04 . Useing the value estimated by software there is a lot of jittery moment of the rotor . But when the value came from user.h it run very well , also DRV8312-69M-KIT can identified the value by software and the motor run well . In order to identified the value by BOOSTXL-DRV8301 & LAUNCHXL-F28027F software what should I do ?