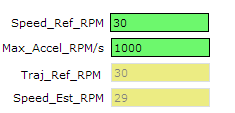

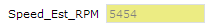

I am working on the FOC labs and I have just finished lab 2c. I have done the labs twice in an effort not to miss anything.

I am reading the forums as well, and I get the impression that at this point the motor should be running close to top speed. Is this correct? Mine isn't if this is correct. Attached are the spreadsheet and user.h file if I need to look at something extra or change something.

Thanks,

David