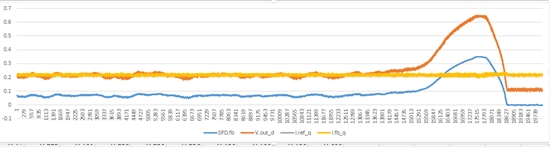

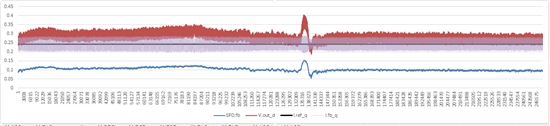

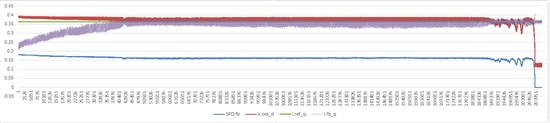

I enable the force_angle to help the motor to start rotation with a heavy load. But some times the force_angle_status keeps 1 so that the motor couldn't accelerate to its set speed. (it rotates very slow, around the force_angle_freq_hz)

I find the Force_Angle_status to be 1, therefore, the controller used forced angle information but not est angle.

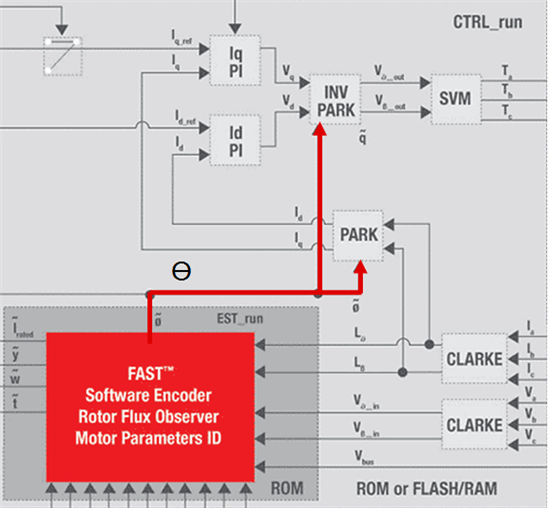

The force_angle should be disabled automatically after FAST est angle estimation converges to let FAST est angle take over the angle input to the PARK/CLARK conversion.

Is that correct? If so, what should I be aware to solve this problem?

Thank you.