Hello,

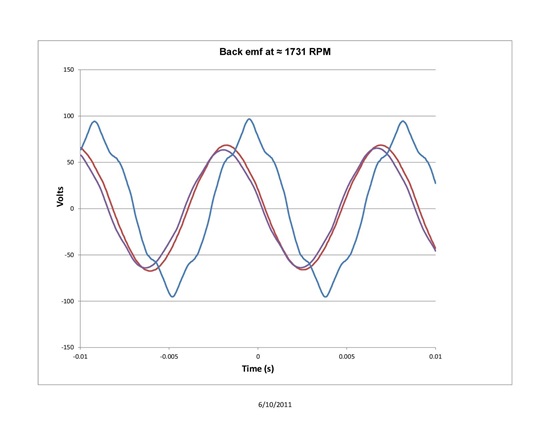

I have been using the older TI motor control software for several years now (since 2010). I have been running a two head air compressor that spins between 500 to 2000 rpm and pulls about 230 watts at max load and speed. The DC voltage to the motor drive is full wave rectified AC of about 150 volts DC under load. The motor is a custom 8 pole 12 teeth BLDC with an IPM rotor. The back emf wave shape is slightly trapezoidal (see non-sinusoid wave in image below), but seems to run fine with the sliding Mode Observer from the older TI code. The winding resistance as measured from line to line is 3 ohms (so 1.5 ohms per phase). The inductance as measured with LCR meter at 1 kHz from line to line is about 18 mH (so 9mH per phase). My old tunning values are as follows:

Fsmo = 0.985

Gsmo = 0.73

Kslf = 0.157

Kslide = 0.5

Speed Kp = 0.6

Speed Ki = 0.005

Speed Kf = 0.0

IqKp = 0.6

IqKi = 0.0318

IqKf = 0.0

IdKp = 0.6

IdKi = 0.0318

IdKf = 0.0

IqRef = 0.6

I have been trying to use the new Insta_Spin FOC with the HV_PFC_Eval kit. When I run Lab 2b I get the following:

#elif (USER_MOTOR == My_Motor)

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4) //8 pole motor ?

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs 1.85

#define USER_MOTOR_Ls_d 0.06921637)

#define USER_MOTOR_Ls_q 0.06921637

#define USER_MOTOR_RATED_FLUX 0.4583907

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (3.0)

#define USER_MOTOR_IND_EST_CURRENT (-3.0)

#define USER_MOTOR_MAX_CURRENT (6.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

When running the lab 2b the motor does seem to stall sometimes even when I increase the current.

Is the motor supposed to stall during this test?

Should I disconnect all load from the motor? Currently the motor is built into a two head compressor, but I do not load the compressor, however, some loading does occur from the friction of the compressor pistons.

When I try to run the motor RPM up to 2000 it stalls. From what I understand the current settings are in amps. If so, it seems these currents are high for what I am used to driving the motor. Typically at max load, I am not driving more than 2 amps, but with this software it seems 3 amps is just barely driving the motor.

My main question is… as long as the old sliding mode observer was able to work with this motor should the new FAST algorithm be able to work as well? Do you see anything about this motor that would concern you with your new software? I have only spent a day working on this, so I may figure a lot more out as I continue my efforts. Just thought i would check with you guys to make sure I am not missing something.

My main goal of switching to the new software is to hopefully gain more starting torque and to utilize the stator winding resistance feedback while the motor is running.