Hello,

at first my setup:

Hardware: LAUNCHXL-F28027 with BOOSTXL-DRV8301 and a custom BLDC motor

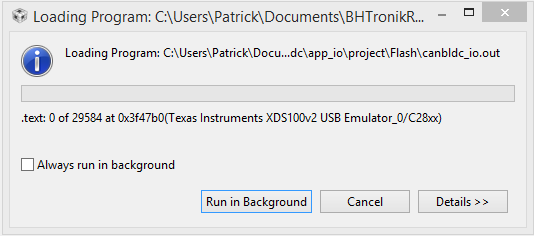

IDE: Code Composer Studio 6.0.0.00190 and GUI Composer 1.0.0.201308252300 (rcp-main)

Software: I'm using a slightly modified LAB10A (sending status and receiving speed/configuration via sci)

My question:

At first we have the motor running with moderate torque from 300-3000rpm which is nice. Nevertheless we got a few problems which have to be addressed.

The first problem is that if the wiring to the motor is cut and "no motor" is connected the software doesn't recognize, it still sends the motor identified flag and reasonable speeds/currents, despite the fact that the connectors are open. Is there any possibility to recognize such a case?

Second while we got moderate strength of the motor in low and higher speeds it's sometimes not enough, especially at lower speeds. We already learned that the influence of Ki and Kp values is rather great but somehow empirical because we have rather complex mechanics attached. Two things: first we are not sure whether our user.h settings match the motor to 100% so it would be kind of you if you could quickly verify that these configurations matches (both attached at the bottom). Second is it possible and reasonable to change Ki and Kp values while the motor is running, so perhaps we have to implement a few sets of values for different speed ranges? Would that be helpful or not?

Thanks in advance for your help!

Regards,

Patrick

Motor parameters:

Supply voltage: 12V

No Load RMS Current: max 0.4A

RMS Stall Current: 12A

Stall Torque: min. 30Ncm

Calc. max. Power: min. 25W

Calc. Efficiency at max. power: min. 40%

Calc. max. Efficiency: min. 60%

Calc. Power at max. Efficiency: min. 15W

Calc. Torque at max. Efficiency: min. 0.05N

Insulation Resistance: <4.5MOhm

Calc. Torque Constant: 3.4Ncm/A

Calc. Motor Constant: 3.1Ncm/W

Calc. Speed regulation constant: 89rpm/Ncm

Calc. Rotor Inertia: 15gcm

Link to my user.h contents using MyMotor as motor:

http://pastebin.com/C57yNPXC