Hello,

Sorry to bother you with a new question.

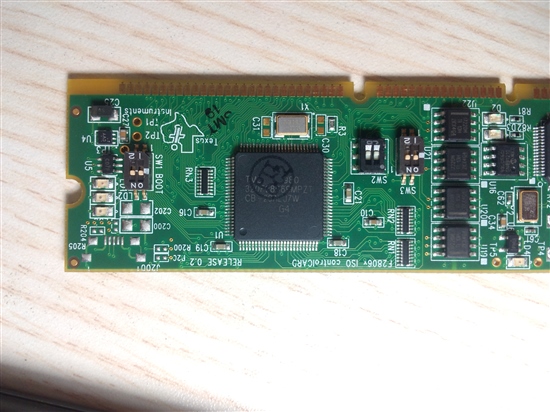

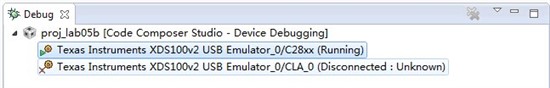

I have spent time trying to identify a three-phase asynchronous motor with InstaSPIN-MOTION, DRV8301-HC-EVM and F28069 ISO controlCARD.

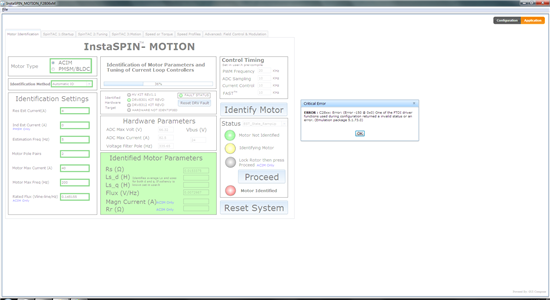

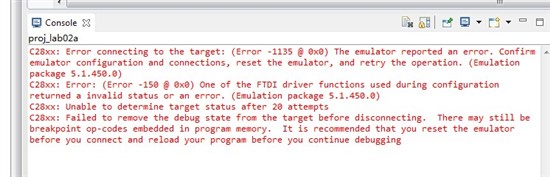

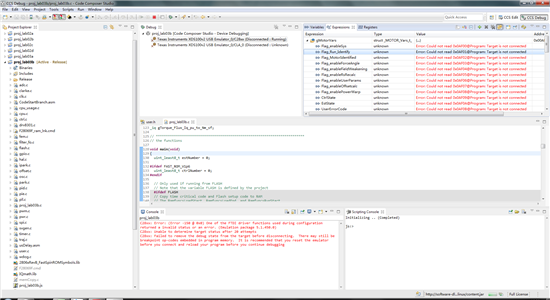

Every time a same critical error occurs on the GUI like this:

So I can’t start my project. I wonder if there is something wrong with my parameters of Identification Settings and Control Timing ? Could you give me some advice ?

Motor parameters:

Model: ZPJ0.75-90S-4

Rated Power: 750W

Rated frequency: 90Hz

Rated voltage: 16V

Rated current: 43A

Rated speed: 2600r/min

Rated torque: 2.5N.m

Thanks very much,

Brant Zheng.