Hi,

I have a problem with demo 12A.

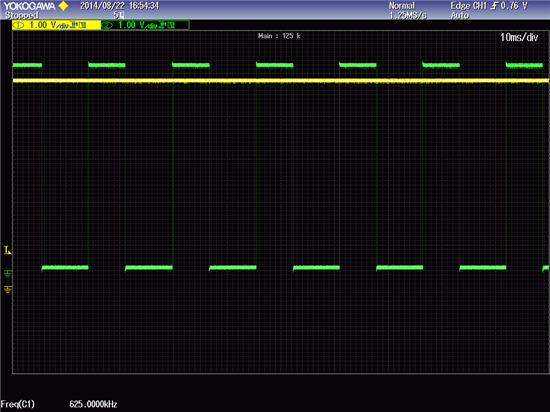

I used demo 3A to check that my motor is running and my encoder is working correctly (scope)

Then I run demo 12A.

What I see is that the motor is toggling only one line from the encoder. motor is vibrating.

Then I got the errors 2003 or 2004. I set the speed as low at 100 RPM and the gMotorVars.SpinTAC.VelIdTorqueRampTime_sec at 1. No luck

I also switched the encoder wires but that didn't work.

So I'm out of options but did I mess-up my user.h

this are my defines.

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.35525)

#define USER_MOTOR_Ls_d (0.0001088917)

#define USER_MOTOR_Ls_q (0.0001088917)

#define USER_MOTOR_RATED_FLUX (0.1576235)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (1.0)

#define USER_MOTOR_IDENT_FREQUENCY_Hz (20.0)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (5.0) // During Motor ID, maximum commanded speed (Hz, float). Should always use 5 Hz for Induction.

#define USER_MOTOR_ENCODER_LINES (75.0) //Encoder( 360 P/R at 4.8:1 reducer) Number of lines on the motor's quadrature encoder

#define USER_MOTOR_MAX_SPEED_KRPM (1) // Maximum speed that the motor

#define USER_SYSTEM_INERTIA (0.1739310026) // Inertia of the motor & system, should be estimated by SpinTAC Velocity Identify

#define USER_SYSTEM_FRICTION (0.2174943686) // Friction of the motor & system, should be estimated by SpinTAC Velocity Identify

48V faulhaber 4490 h motor

Any suggestion?