Dear all,

I want to use the DRV8301-69M development kit to evaluate the sensorless control of a PMSM motor in generation mode. An external speed is applied to the motor under test and a reverse break torque is applied to the driving motor. I have modified example 4 "Torque Mode" from the motorware labs. The DC bus is extended with a chopper and break resistors to absorb the regenerated energy.

The principle works fine for the moment, but I have to solve some issues:

1. Low speed: When running at low speed (< ~1RPM), it's not possible any more to control the motor properly. Especially at higher torques. I disabled already the forced angle, which improved already the results, since the driving motor is controlled in speed and we want to break with constant torque.

On the forum I saw TI is working on algorithms (eSMO, HFI) to improve low and zero speed control. This is available in the controlsuite. Will this become available in the motorware and if yes, do you have a timing for this?

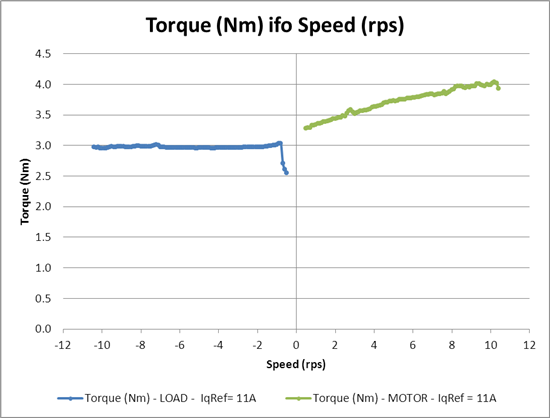

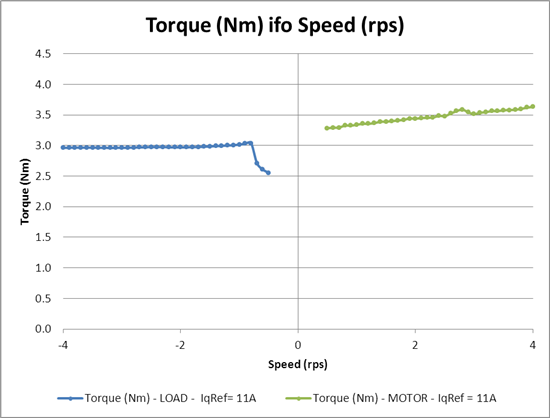

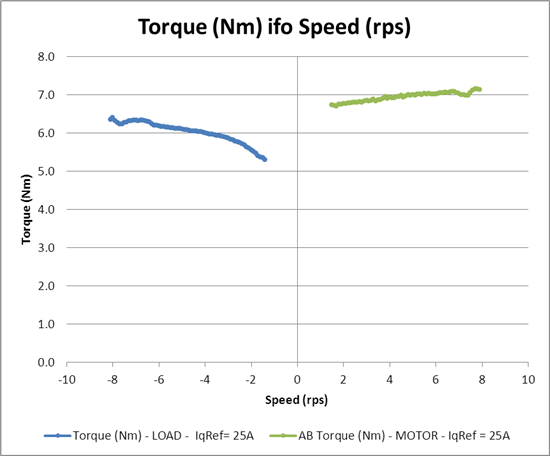

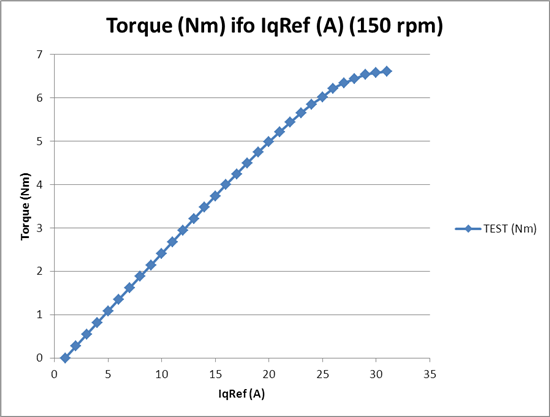

2. When I request a constant Iq (= constant torque since Lq = Ld) to the motor under test and the applied driving motor speed is varying, I can see the torque increases with an increasing speed (Torque increases ~1Nm if speed varies from 1 to 10 rps) while the estimated torque is more or less constant over speed. [measured without Rs online calibration]

3. At higher speeds and higher torques, the speed and torque estimations becomes instable. [No Rs online recalibration]

4. I tried already to enable the Rs online compensation to compensate the Rs resistance but I'm not able to get proper values from the online compensation. The online Rs value oscillates around a certain value (which influences the estimated torque). Is it possible the online measurement doesn't work that good for non-silent motors (Lq not equal to Ld)?

Motor specs:

- Stall torque 9.7Nm

- Torque constant 0.388Nm

- BEMF constant 23.6V

- Ld = Lq = 0.6mH

- Poles 32

Thanks in advance for your inputs!

Best Regards 3s