Sir,

Motor Used : Motor Power TC80-2.8-21 model Having

Rated Speed = 3000 @230VAC, Rated Torque = 2.6Nm ,

Rated Current = 3Arms, and Encoder PPR = 2000.

My Setting,

#define USER_MOTOR_TYPE MOTOR_Type_Pm

#define USER_MOTOR_NUM_POLE_PAIRS (4)

#define USER_MOTOR_Rr (NULL)

#define USER_MOTOR_Rs (0.7422892)

#define USER_MOTOR_Ls_d (0.003110148)

#define USER_MOTOR_Ls_q (0.003110148)

#define USER_MOTOR_RATED_FLUX (0.3917434)

#define USER_MOTOR_MAGNETIZING_CURRENT (NULL)

#define USER_MOTOR_RES_EST_CURRENT (1.0)

#define USER_MOTOR_IND_EST_CURRENT (-1.0)

#define USER_MOTOR_MAX_CURRENT (1.00)

#define USER_MOTOR_FLUX_EST_FREQ_Hz (20.0)

#define USER_MOTOR_ENCODER_LINES (2000.0)

#define USER_MOTOR_MAX_SPEED_KRPM (3.0)

#define USER_SYSTEM_INERTIA (0.05456888676)

#define USER_SYSTEM_FRICTION (0.05014914274)

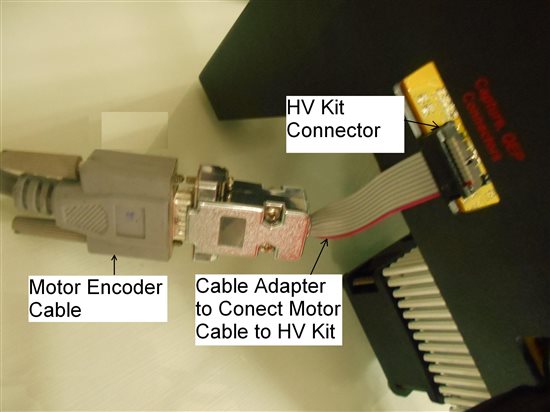

I am using HV kit , In lab 12 I connected the encoder appropriately with the kit and have tested this by

variable "st_obj.vel.conv.Pos_mrev" which comes around '1.0' on one full manual rotation of motor shaft. And even Added a long variable in program "EncCounts " which i m monitoring in watch window, which come around 8000 on full manual rotation of motor shaft.

EncCounts = ENC_getRawEncoderCounts(encHandle); //Used in watch window to debug.

Now the problem is ,

When "gMotorVars.Flag_enableSys" & "gMotorVars.Flag_Run_Identify" is set to 1.

I monitored the encoder counts its varies even though the motor shaft is stationery.

Then Motor velocity run with varing speed (Sometime it run with high RMP and Some times in Low RPM) and stops in between speeds. Even though in this whole process my RefSpeed is 100RPM.

Please (Below image) have a look at cable adapter made to connect motor encoder cable with the HV Kit.

Motor Encoder Cable is shileded but the adapter here is a Bus Strip which is not shielded. Will this create a problem???

If this is the problem ...How to Cable the motor connector to KIt to eliminate Noise??