Happy new year Adam and Chris!!

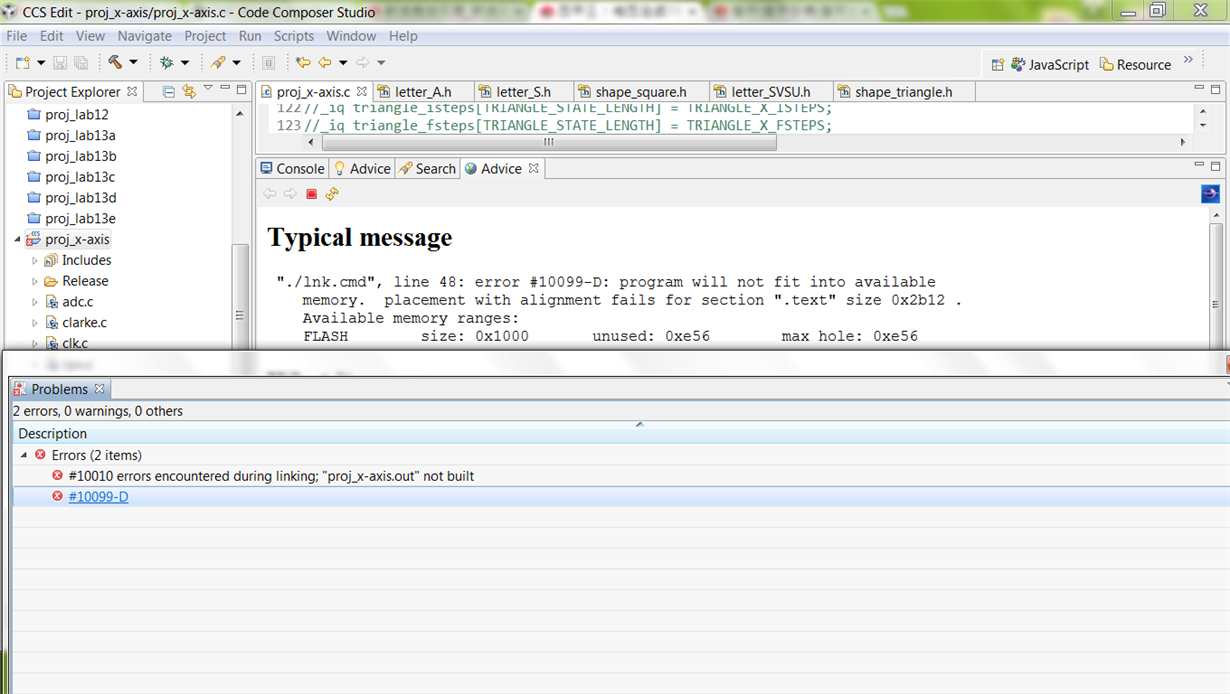

Working on the 2d CNC using given example codes on MW11. I found no problem on the INDIVIDUAL motion from X and Y-axis. But they are not correctly cooperating. In square plot, by given settings in STPOSPLAN_addCfgState, it suppose to have the bottom case (attached); but it (top one is what I actually obtained) is not and obviously, x is not waiting until y is done; and y is not following x-to-go signal either.

What do you think, why the Transitions are not following the Conditions in motion sequence? I connected gpi041 and 40 between two drv boards; and press START on both boards at the same time (tried my best) to run them (I'm not running thru. flash). Any mistake in my operation?

Thank you for help.