Hi

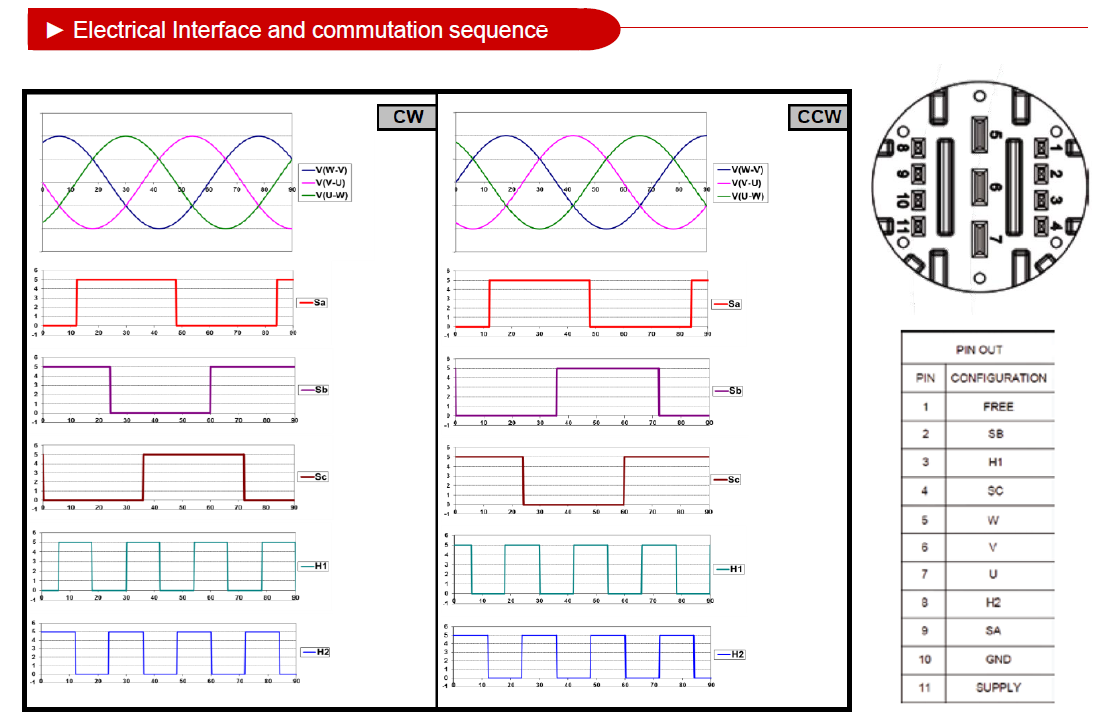

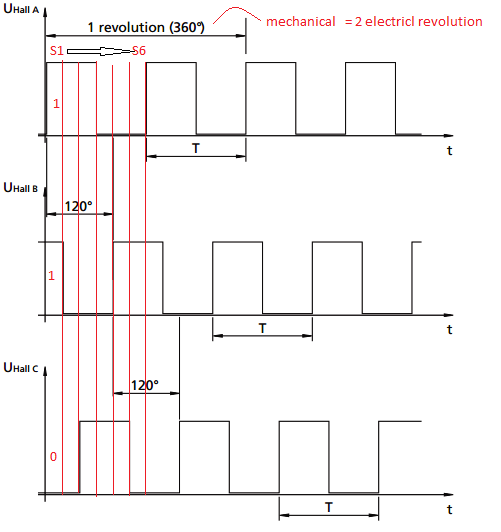

We are experiencing a problem using the TI evaluation board DRV8301-HC-EVM Rev D powering a Sonceboz motor (model 5642 - 5 pole pairs, low inductance). Our problem occurs when using lab 12b for velocity control with quadrature.

If we use a 1000 line encoder feeding into the QEP, we get one of two behaviours depending on the starting angle of the motor: either it is fine, or it runs backwards at full speed. When running backwards the problem appears to be something to do with the output – the velocity speedQEP_krpm is correctly measured as large and negative, the error signal is large and the controller is requesting (and getting) maximum current. The motor has 12 detents and starting from half of these gives the problem, the other half gives perfectly normal control. It is completely repeatable. If we use the FAST estimator instead of QEP (lab 5d), it works correctly in all start positions (although the RPM is not very smooth).

When working normally, EST_getAngle_pu() and ENC_getElecAngle() track reasonably well. When not working, the former angle rises as before but the encoder derived angle falls very slowly for about one (electrical) revolution; then both angles change so quickly that we cannot sample them.

Thanks for any help.