Hi,

I am having trouble tuning the VLM33J servo motor I am testing. I’m using lab 12b and running sensored. Using SpinTAC the load regulation is not as good compared to the same motor with a commercial servo drive.

Inertia was estimated in Lab12a. The inertia estimate of 0.872 was within 28% of the calculated value of 0.680. I also noticed that different Kp_Idq settings give slightly different inertia estimates. I mention this because it may play into my problem.

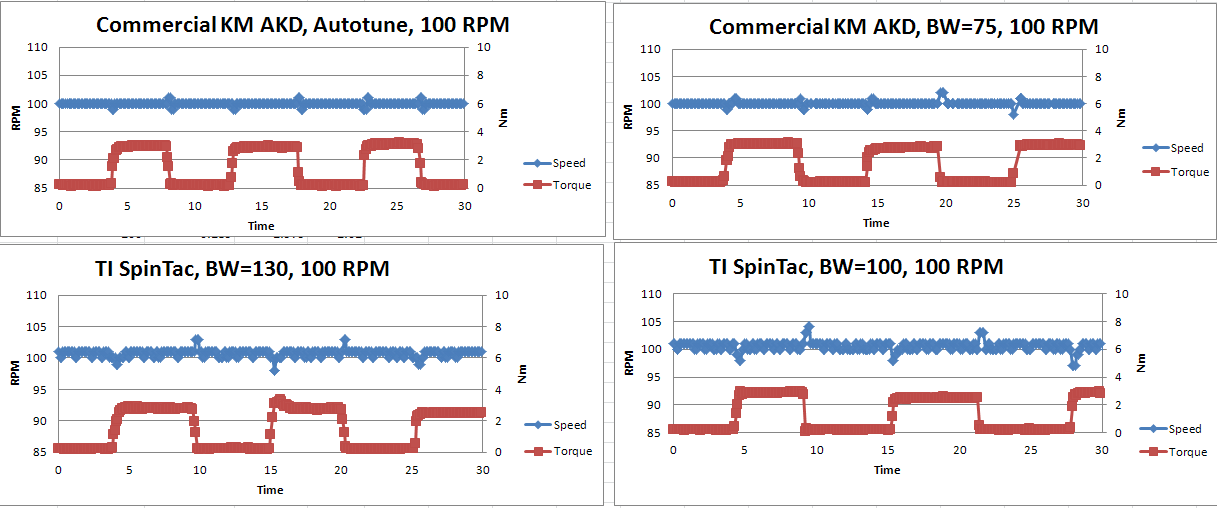

Using Lab 12b with two bandwidths (100 and 130) the data below was taken comparing SpinTAC to a commercial servo drive. The same motor, encoder, and load setup was used. When the load is changed (0 to 3 Nm) the commercial drive’s speed has less disturbance. The commercial drive auto tuned and slider tuned are the top two graphs, SpinTAC with BW of 130 and 100 on the bottom graphs. Hopefully you can see the speed changes are much more on the bottom graphs.

I've tried other bandwidth settings. With lower bandwidths the speed disturbances are even greater, and with higher bandwidths the speed changes are smaller, but running at higher speeds (500 RPM, 1K RPM) the motor is noisier and the system vibrates more.

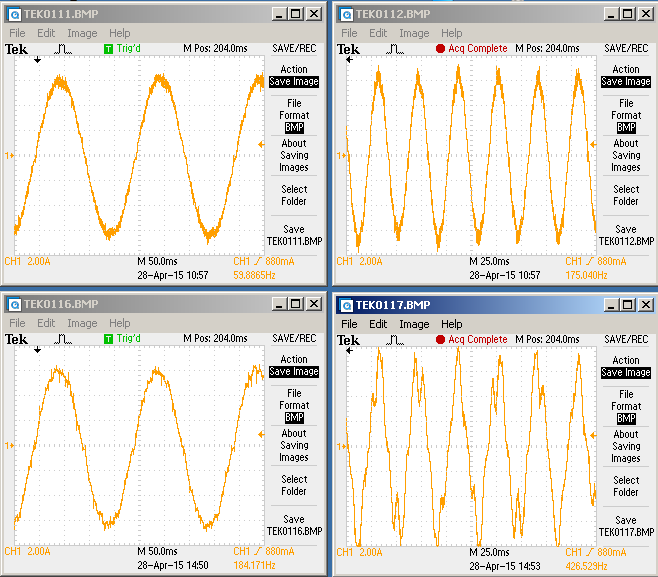

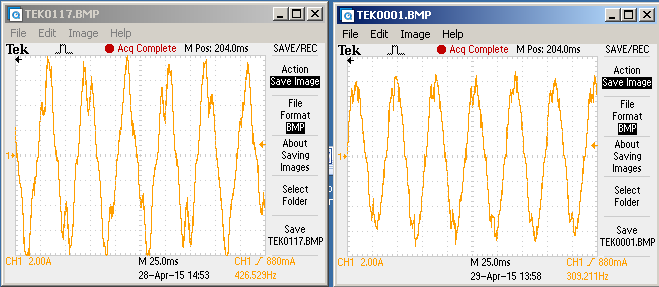

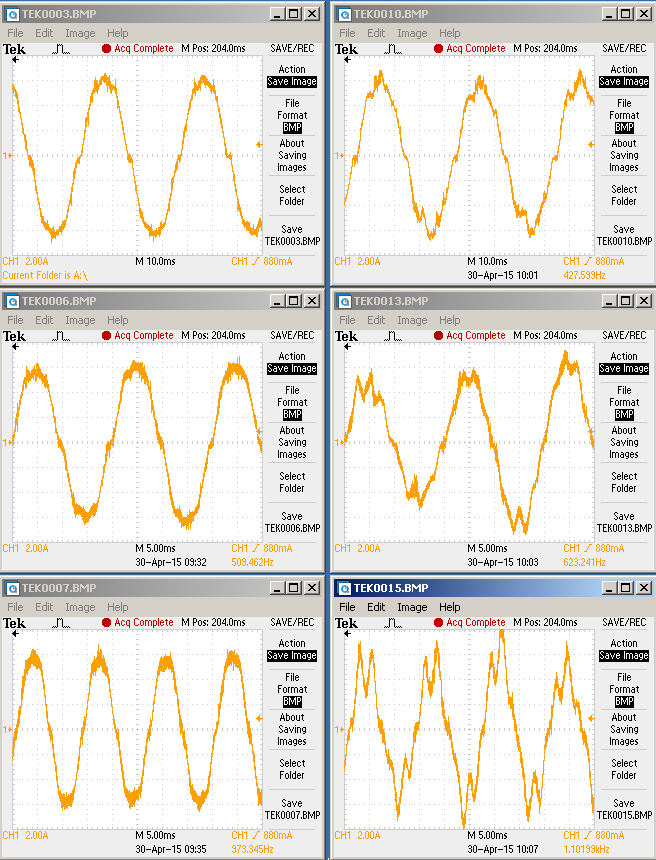

These tests were done with Kp_Idq set to 0.40. I've tried other proportional gains but this seems to give the best performance. Below are the current signals for the commercial drive and SpinTAC. The commercial drive at 100 RPM and 500 RPM are at the top. The SpinTAC/TI drive at 100 RPM and 500 RPM are on the bottom. At 100 RPM the two look similar, but the SpinTAC signal at 500 RPM looks bad. This is certainly causing some of the vibration.

I am not sure of how to better tune the motor. At zero speed and bandwidth of 130 with no load, if you take the shaft of the motor and rotate it 90 degrees, it seems fairly tight and snaps back to position with little oscillation. So it feels tuned OK. But for the same setup, with the commercial drive the shaft is harder to turn and stiffer. I don’t understand this because looking at the current waveform while doing this test, both waveforms look similar. Why would 6 Amps of current feel weaker with TI than the commercial drive.

Please provide any suggestions on how to better tune this motor.

Thanks.